Minimal Operator Variables with PaveAnalyzer

BY Khaled Hasiba, P.E

Minimal Impact of Operator Variables when using the Automated Extraction Machine (PaveAnalyzer) for asphalt binder and filler extraction from Asphalt Mixtures (Preliminary Results)

Background on the Automatic Extraction of Asphalt Binder

This test method is used to quantify the amount of bitumen in asphalt mixtures for specification acceptance, quality control and assurance, and research purposes. The automatic closed system offers a safer work environment for asphalt technicians since all fumes are encapsulated inside washing drum, which eliminates the exposure to toxic materials. It involves washing the binder off the aggregates using solvent and ultrasonic motion, separating the fines from the binder in a centrifuge, and recycling the solvent by separating it from the asphalt binder through a distillation and condensation process. The aggregates and fillers are then dried by forced air circulation.

Experimental Laboratory Study

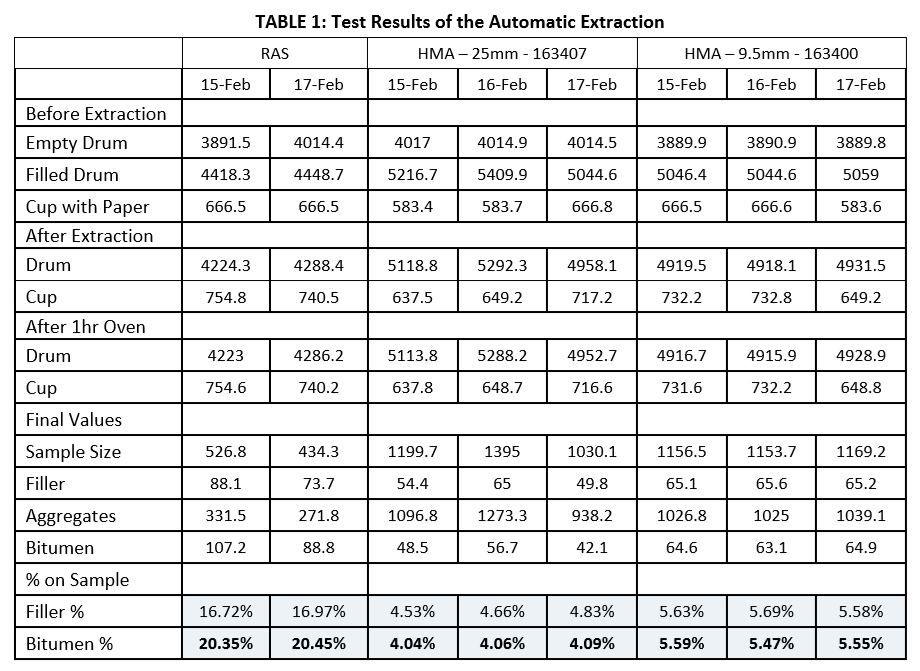

An internal laboratory study was conducted by Controls Group USA to assess the impact of human error involved in operating the PaveAnalyzer equipment during the automatic asphalt extraction. Two research engineers from different operation offices performed automatic extraction of asphalt binder on three (3) different asphalt mixtures: recycled asphalt shingles (RAS), and two (2) Hot Asphalt Mixes (HMA) of Nominal Maximum Aggregate Size (NMAS) of 9.5mm and 25.0mm. Both mixes included 15.0% of Reclaimed Asphalt Pavement (RAP).

An internal laboratory study was conducted by Controls Group USA to assess the impact of human error involved in operating the PaveAnalyzer equipment during the automatic asphalt extraction. Two research engineers from different operation offices performed automatic extraction of asphalt binder on three (3) different asphalt mixtures: recycled asphalt shingles (RAS), and two (2) Hot Asphalt Mixes (HMA) of Nominal Maximum Aggregate Size (NMAS) of 9.5mm and 25.0mm. Both mixes included 15.0% of Reclaimed Asphalt Pavement (RAP).

The study was conducted between February 15th and 17th 2017 in Controls Group’s facility in Milan, Italy. Tests on February 15th and 16th were conducted by the same researcher, while test on the 17th were performed by the second researcher. Both HMA mixes were collected from one source in the state of Indiana, while the RAS samples were collected from one source in the state of Texas.

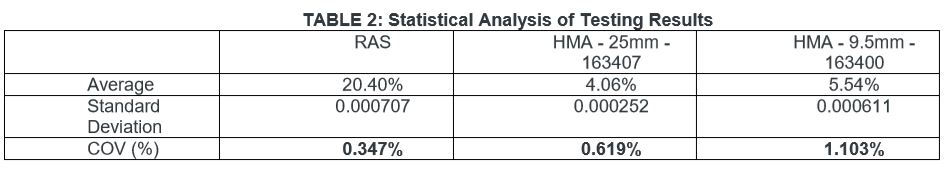

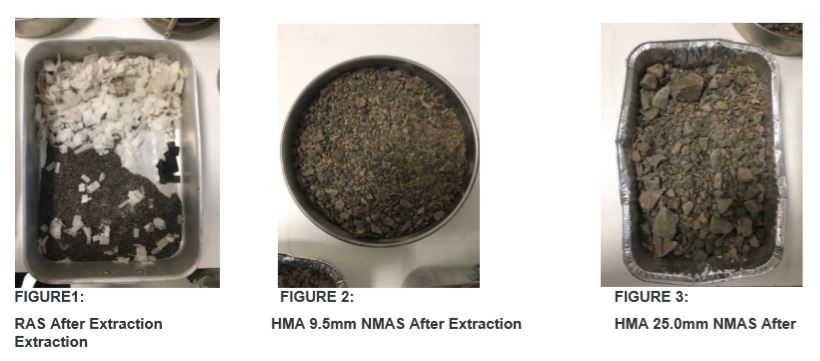

The study showed very low variation between both operators when utilizing the automated extraction methodology. This is referred to the full automation of operation during washing the binder off the aggregates, separating the fines particles in the centrifuge and recycling the solvent in the asphalt tank. The study yielded coefficient of variations of 0.338%, 0.545%, and 1.079% for RAS, HMA 25mm NMAS, and 9.5mm NMAS, respectively. Table 1 and 2 present the testing data and the statistical analysis, while Figures 1, 2 and 3 show images of the washed aggregates and fibers after extraction and drying is completed.

Conclusion

The above study and figures demonstrate that there is minimal impact from operator variables on the results when bitumen and filler content is analysed using the PaveAnalyser.

If you have any question, please feel free to contact Khaled Hasiba, P.E. at: khaled.hasiba@controls-group.com +1 847 551-5775