Tips to Maintain your Haul Truck

BY Sandy Lender

Save on Costs with Your Professional Guide to Asphalt Mix Delivery

Part 1—Take a New Look at Haul Truck Maintenance

For the 2017 paving season, we dive into an essential area of project management for asphalt professionals: safe and timely delivery of hot-mix or warm-mix asphalt (HMA/WMA) to the paving site. During this eight-part series, you’ll get some back-to-basics best practices to share with veteran and new haul truck drivers, in addition to new tips, ideas, and case studies with logistics and technology that will enhance your bottom line. Producers have streamlined processes at the plant; contractors have nailed down best practices in the work zone. Now it’s time to harness the potential you’ve been missing when it comes to mix delivery and haul truck fleet management.

Let’s start with minimizing downtime. At first, that sounds like an old discussion of routine maintenance; but we’re going beyond the routine with this series.

Keep in mind, according to the Federal Motor Carrier Safety Administration (FMCSA), you must display a periodic inspection decal that proves your commercial motor vehicle (CMV) has been inspected within the past 12 months, but that decal doesn’t prevent “surprise” roadside inspections. In other words, the decal proving you’re in compliance merely protects you from being cited for a violation of periodic inspections. Operating a commercial vehicle means a state or federal inspector can stop you if they notice something that appears unsafe.

This behooves you to perform routine maintenance for best and safest operation in between your mandatory periodic inspections. Drivers must prepare a driver vehicle inspection report (DVIR) at the completion of each day’s work, and must turn those in to the company, but that’s only half the story.

Maintenance is Your Responsibility

All trucks must have a clean and visible “Construction Vehicle—Do Not Follow” sign. It’s the law. Part of your daily, pre-shift walk-around should include looking at this sign to ensure it is clean, legible and in good repair. Photo courtesy John Ball of Top Quality Paving & Training, Manchester, New Hampshire.

The haul truck driver is responsible for delivering sand, aggregate, millings, or a hotbox of one to five tons up to a body of 20+ tons of 300oF perishable asphalt mix. That’s heavy duty hauling for the road-building industry, which means the truck has got to be up to par.

One of the most important items to ensure is working on your truck is the backup alarm. Many companies have instituted the policy that a haul truck with an inoperative backup alarm will not be allowed on a job. This means an independent driver could show up with a load of material and get kicked off the job, making him financially responsible for 18 or so tons of cooling mix.

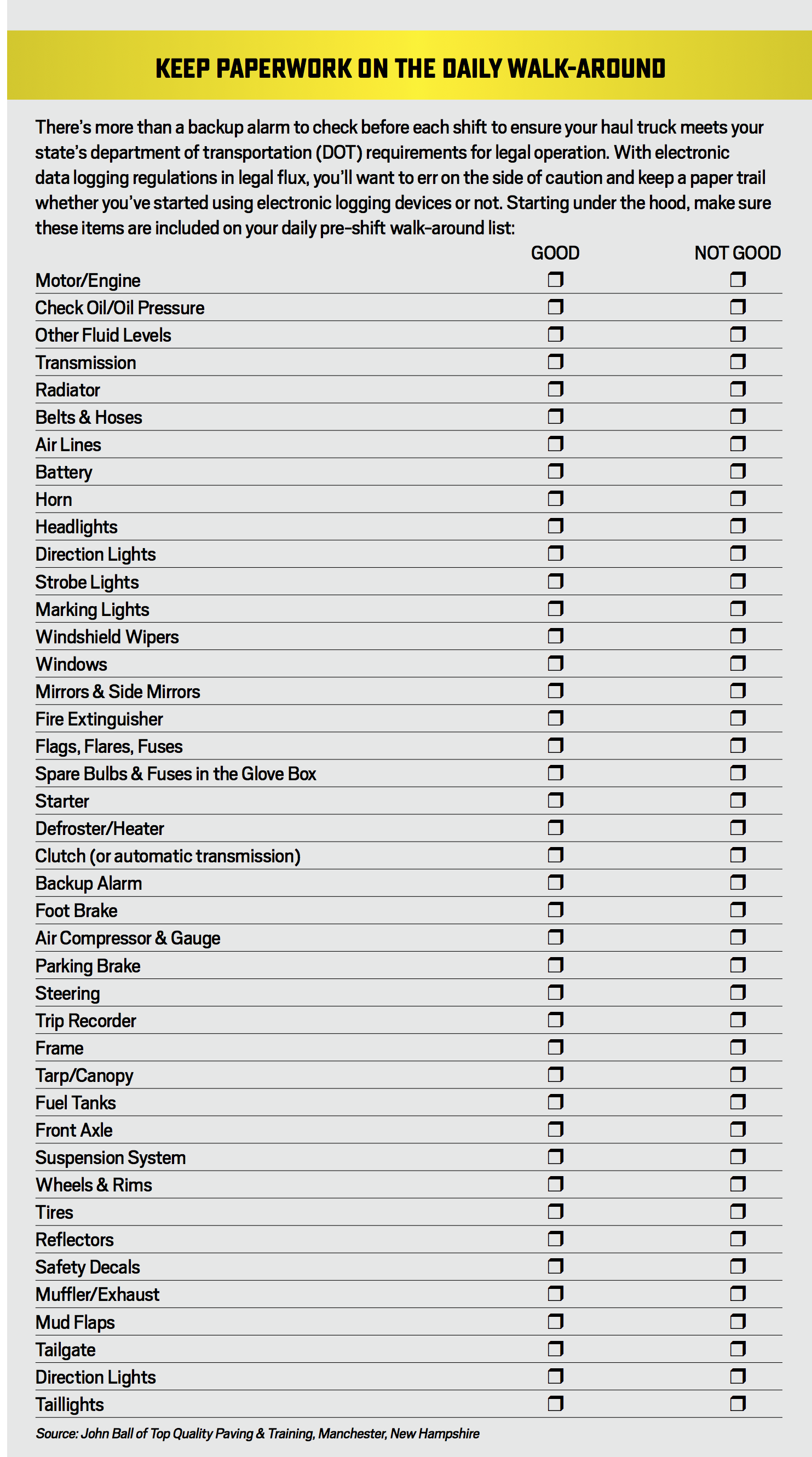

Of course there’s more than a backup alarm to check prior to each shift to ensure your haul truck meets your state’s department of transportation (DOT) requirements for legal operation (See Sidebar “The Daily Walk-Around” on page xx). Independent driver Steve Murray of Steve Murray Trucking, Hooksett, New Hampshire, has a routine even after he’s completed his daily inspection, but before he gets to the jobsite.

- Rinse the truck off with a 1,000-pound pressure washer.

- Make sure the windows and mirrors are clean for visibility.

- Make sure the lights are working.

- Clean the body so there’s no residue.

- Then go to the job for instructions.

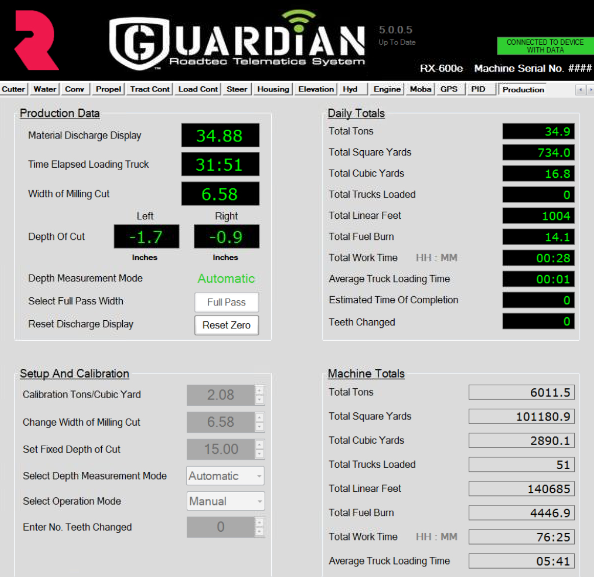

To track maintenance activities, drivers and mechanics have the help of modern technology. Even before large original equipment manufacturers (OEMs) joined forces to standardize data points, they were developing telematics to gather information on the way engines run, to detect faults in equipment, to schedule maintenance actions, to streamline machine safety, to monitor emissions controls, and to gather data for fleet management.

These are concepts that cross the entire equipment fleet; they’re not unique to the haul trucks in the yard. For instance, the team at Volvo Construction Equipment has telematics packages standard on 7 articulated haulers, 23 excavators, 11 wheel loaders, and as an option on two pavers, 2 soil compactors, 4 asphalt compactors, 4 compact wheel loaders and 8 compact excavators. Then the Volvo Trucks team has the Gateway telematics system to monitor and gather data for commercial vehicles.

Other OEMs have recently released telematics solutions for on-highway trucks. In March, Caterpillar announced its on-highway truck fleet solution complementing telematics that are already standard on their construction equipment. Their VisionLink interface will now combine telematics information from virtually all assets on a jobsite including on-highway trucks, giving customers a powerful asset management tool, as well as keeping customers’ heavy duty trucks compliant with federal regs concerning an electronic logging device (ELD), which will be discussed in more depth in a future installment of this series.

Telematics is, at its core, machines talking to machines. Back in the mid-2000s, OEMs recognized that many contractors have mixed fleets, which meant the end user had mixed data coming in on different types of screens. Different machines were failing to talk to one another in different languages. That had to be reconciled some way.

By Feb. 5, 2010, a team of OEMs developed and released a “first” standard with a set of data points—hours, odometer, fuel, location, date/time and machine identification information—that all OEMs could incorporate in a telematics package. The idea was to let all OEMs’ machines talk to each other in the same language when “talking about” those specific data points. Fleet managers know there are more data points than the six listed in this paragraph, and OEMs kept working to make the standard more robust for the end user. The International Organization for Standardization (ISO) published the final standard—I5143-3—Nov. 30, 2016.

This gives contractors and fleet managers confidence that the data-monitoring across the fleet is gathering, interpreting and delivering information in a uniform manner.

You’re Responsible…Except When You’re Not

Under the PC-11 standard, you’ll find new oil specified for your Tier 4 compliant engine. If you pick up the API CK-4, it is designed to work optimally with older and newer engines. If you pick up the FA-4, it is designed to work optimally for the 2017 engines.

No matter what tier level your engine is, you are responsible for keeping it, and the components surrounding it, in top working condition. You’ll want to test the freezing point of the coolant before winter—every winter. Check the belts and hoses on a regular basis, too. Make sure the air cleaner indicator gives you a good reading.

Consider the new after treatment systems available now. You want to monitor whichever system your engine manufacturer uses and perform basic maintenance as the OEM recommends. Pay close attention to the type of lube oil the manufacturer recommends, which we’ll discuss further in just a moment. The team at Wolter Group LLC, Brookfield, Wisconsin, reminds you,

“The after treatment will not function properly unless you use the specific low ash oil.”

Something to be aware of when dealing with your Tier 4 engine is liability. While you can take care of routine cleaning and checks on your own, error codes indicate problems that may require professional help. During the “What’s Now” Speaker Series that took place on the CASE Construction Equipment stage during CONEXPO-CON/AGG 2017, Dave Piech, who is the vice president for engine compliance NAFTA, CNH Industrial, shared emissions regulatory news and what he anticipates for future emissions standards. He mentioned onboard diagnostics (OBD) and liability.

OBD offers advanced—and advancing—technology to assist operators, but the “right to repair” comes into question. If you receive a warning light or fault code from your OBD regarding your Tier 4 engine, you may be breaking the law if you make the repair yourself. Piech explained that changing the way an engine runs has both safety and environmental impacts. “If anybody goes in and adjusts how an engine runs, that may be a violation of the law,” he said.

Wolter Group states on its website: “It is best to check with the engine manufacturer representative first before replacing the oil or coolant. Additionally, if there is an error code flashing on the display, your best bet is to call the nearest servicing dealer so they can diagnose and fix the problem.”

Part of your responsibility in maintenance is to change the fluids and filters under the hood regularly. Think about oil changes for a moment, because even this tried and true, routine maintenance item saw change as of 2016.

As fleet managers may have recently learned, heavy duty engine oils (HDEO)—labeled API CK-4 and FA-4—are part of the nomenclature in the Proposed Category 11 (PC-11) oil standard that hit the marketplace December 2016. PC-11 is the category in which we find the CK-4 and FA-4 specs. Some of the goals of upgrading from the former CJ-4 oils to the PC-11 category are to protect engines no matter what level of shear stress the oil will undergo in the engine, to protect against oil breakdown due to oxidation under higher operating temperatures, and to safeguard fuel economy.

We’ll lean on the Shell ROTELLA® Products website at rotella.shell.com for a breakdown of what’s different about the high temperature high shear (HTHS) viscosity oils available to the marketplace:

In order to meet goals for more fuel-efficient engines and fewer emissions, many next-generation engines will run at higher operating temperatures. This will require changes in engine oil composition, so they can withstand more heat without sacrificing engine protection. It will also mean that instead of one category of engine oils, we’ll have two—CK-4 and FA-4. CK-4 engine oils will be a direct replacement for the engine oils you’re using now. You’ll be able to buy the same viscosity grades and oil types (conventional, full synthetic, synthetic blend) you’re using now, and they’ll be “backwards compatible” to ALL current vehicles. They’ll just also conform to the new PC-11 standards. The new FA-4 engine oils will be offered in lower viscosity grades and are designed primarily for next-generation engines to help maximize fuel economy without sacrificing engine protection. These FA-4 oils may have limited backwards compatibility, and would be labeled as such.

If you feel the need to spend seven or eight minutes on this, Chevron has prepared a series of short videos at www.deloperformance.com debunking myths about PC-11 and the like. The point for this article is to let you know that you’ll find new oil specified for your Tier 4 compliant engine. If you pick up the API CK-4, it is designed to work optimally with older and newer engines. If you pick up the FA-4, it is designed to work optimally for the 2017 engines.

Maintenance Matters For the Quality of the Job

Telematics is, at its core, machines talking to machines. The Guardian system from Roadtec, an Astec Industries company, allows machines to notify mechanics, operators or even personnel back at the OEM headquarters when it’s time for routine maintenance or when a system has “moved” out of its optimum settings. Depending on the type of package—or subscription—the contactor has opted into, a technician in the home office or OEM’s office can troubleshoot remotely or send a mechanic to perform maintenance in a timely fashion. Photo courtesy Roadtec, Chattanooga.

Keeping the haul truck in top notch condition does more than keep you in compliance with the DOT. If you’re an independent driver, you want contractors to hire you again, thus having a truck that contributes to bonus-worthy quality works in your favor. If you’re part of a company that maintains its own trucking fleet, each vehicle is a piece of the paving puzzle. Each piece requires maintenance for optimum performance. Start at the top.

You want to inspect the tarp—or canopy—each day to ensure it has no rips or tears. Look at the mechanism that lowers and raises the canvas to ensure it moves smoothly and completely. In other words, you don’t want the device to stop short, leaving the tarp to hover a foot or two above the HMA in the bed. This leaves room for wind to whip in and cool the top of the material into a segregated shell while you drive from the plant to the job site.

Independent driver Steve Murray Trucking’s Murray installed a Slide-n-Go cover system from Cramaro of Stuart, Florida. This system runs on two cables that unroll and retract the canvas along rails, forming a l

id on the truck body when closed. “If you have arms on the cover, you have to watch those don’t hit wires,” Murray cautioned.

“With the system Murray has, it holds the heat in the body,” John Ball of Top Quality Paving & Training, Manchester, New Hampshire, said. “You don’t want the tarp flapping like a sail as you drive down the road. You’ll lose heat from your perishable material.”

While inspecting the tarp before your shift begins, look into the truck bed. You’ll want to make sure it’s clear of clumps of yesterday’s mix, of course, but look for debris that may have blown in overnight. Take the time to pick out plastic wrappers, soda cans and anything else that has gotten in. Anything you see in the bed of the haul truck will get covered with mix and then will get carried into the hopper of the paver. Once it’s in the hopper, it will likely go into the mat, creating a quality control problem that spells deducts later. As the haul truck driver, you can stop that financial loss with just a few minutes of cleanup during your pre-shift walk-around.

Another way you can make your vehicle appealing to the paving crew is to make it compatible with paving equipment.

For example, does your haul truck have a trailer hitch at just the right height to “grab” and tear the rubber on the front of the hopper? That leads to a potential mess each time trucks charge the hopper—giving laborers extra shoveling to do and an extra repair for the mechanic. The crew won’t be excited to re-hire you if you tear up the equipment. Instead, remove the trailer hitch on those weeks when you’ll be hauling asphalt.

Your truck will be more compatible with the paver if you can get the mud flaps out of the way, as well. Each individual state department of transportation (DOT) has different requirements of haul truck mud flaps—splash guards. You won’t find guidance on the FMCSA site because it doesn’t dictate policy on this item, but your state DOT will have regulations for the height the flap can hang from the ground, how much of the back tire it must cover, and the angle of flying debris it is to block. Check with your DOT’s website to make sure you start out in compliance. Then look into systems for easily lifting the flaps out of the way.

When you back the truck to the paver, you stop before making contact. When the paver operator moves the paver forward and brings the push rollers into contact with your vehicle, the push rollers are to touch the back wheels of the haul truck. If the mud flap is in the way, the push rollers now have the opportunity to deliver a jerking motion as the tractor moves forward. This will cause segregation in the mat. The push rollers also have the opportunity to tear the mud flaps. This means a repair for you later and possibly a chunk of polyurethane in the mat, which is another quality control problem. The push rollers also have the opportunity to leave asphalt mix on the mud flaps, which means more cleaning for you at the end of your shift. None of those scenarios is an efficient use of time or materials.

Instead, look for a system that will let you press a button in the cab to hydraulically lift the mud flaps when you enter the paving work zone. Or use this idea from Murray. He has extended the outer flaps of his rig from heavy duty chain.

The chains keep the flaps hanging at the proper height for his DOT regs, and allow him to physically place the flaps on the fenders to keep them out of the way while he discharges the load. Check out Part 4 of this series, Move the Mud Flaps Out of the Way, next month for a full explanation.

As you can see, haul truck maintenance goes beyond changing fluids and filters on a regular basis. It goes beyond handling the big emergency repairs that crop up. By performing daily inspections and regular maintenance, you keep your vehicle in compliance and enhance your ability to contribute to a quality paving team.