How to Perform Degassing of New Asphalt Samples in the Lab

BY AsphaltPro Staff

As we discussed in this department last month, there are many benefits to testing mix designs in a lab setting prior to placing pavement on a roadway. One of the limitations is replicating the real world in the lab. Among the tools lab technicians use to replicate the real world is forcing “age” upon the new mix with the pressure aging vessel. One of the errors or problems that might creep in when a pavement is artificially oxidated at an accelerated rate is “bubbles.”

Samples being degassed in one of the four Prentex VDO 9900 models may be monitored visually through the glass viewing window located on the unit’s cover.

American Association of State Highway and Transportation Officials (AASHTO), American Society of Testing Materials (ASTM) and European Standards (EN) are entities that regulate how testing is performed so everything is up to highest quality. As we detailed last month, aging a mix in a lab falls under AASHTO R28, ASTM D6521 and EN 14769 test standards, and manufacturers of pressure aging vessels (PAVs) and vacuum degassing ovens (VDOs) build their hardware and software to meet those standards.

The VDO is designed specifically to remove the air bubbles introduced during the accelerated oxidative aging of the mix in the lab. In fact, the team at Controls Group/IPC Global explains on its website those standards listed above require degassing or removing the air bubbles—conditioning the sample—before you move on to further testing. “This final conditioning makes the aged binder suitable for further tests such as BBR, DSR, penetration, ductility, softening point and many more.”

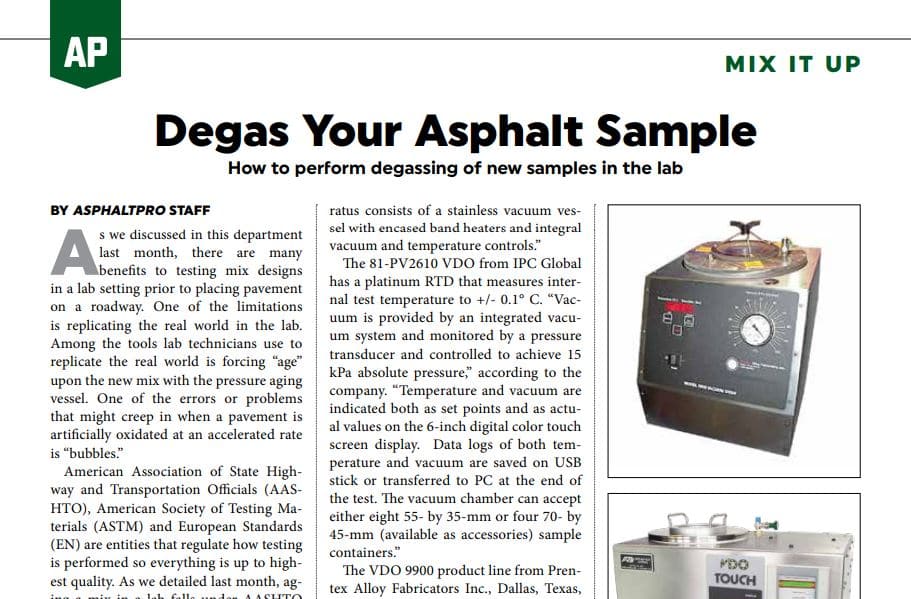

The VDO Touch from Applied Test Systems is a next generation model incorporating updated software and touchscreen capabilities.

The VDO is the machine that makes conditioning “easy” for the lab tech to move on to those additional tests. We don’t want to imply the manufacturers have dumbed it down, but the VDOs available on the market are designed to remove the unwanted air from samples at a stable temperature for the lab tech. Controls describes them like this: “The apparatus consists of a stainless vacuum vessel with encased band heaters and integral vacuum and temperature controls.”

The 81-PV2610 VDO from IPC Global has a platinum RTD that measures internal test temperature to +/- 0.1° C. “Vacuum is provided by an integrated vacuum system and monitored by a pressure transducer and controlled to achieve 15 kPa absolute pressure,” according to the company. “Temperature and vacuum are indicated both as set points and as actual values on the 6-inch digital color touch screen display. Data logs of both temperature and vacuum are saved on USB stick or transferred to PC at the end of the test. The vacuum chamber can accept either eight 55- by 35-mm or four 70- by 45-mm (available as accessories) sample containers.”

The VDO 9900 product line from Prentex Alloy Fabricators Inc., Dallas, Texas, consists of four models and degasses using an integrated self-contained vacuum oven. The vacuum is controlled by a digital microprocessor with the vacuum pressure indicated directly in kPa absolute. The Prentex website states this provides the operator “with simplicity of operation and reducing the chance of error in performing the degassing process.”

The Prentex team differentiates its models from others on the market by explaining its vacuum oven does not measure the temperature of the vacuum. “Instead, our device measures where degassed asphalt temperature has shown to stabilize; namely, at the aluminum support for the sample tins, which is machined from ¼-inch [6.4-mm] thick aluminum.”

Applied Test Systems, Butler, Pennsylvania, offers the ATS Vacuum Degassing Oven (VDO Touch), which is the next generation ATS VDO incorporating updated software and touchscreen capabilities. It is a benchtop unit with leveling legs and is part of ATS’ CE-approved asphalt bitumen/binder testing line. The manufacturer states it is NIST traceable RTD for temperature measurement, with an accuracy of +/- 1°F. It includes a USB port on the front of the unit for upgrades and data downloads and has programmable temperature, soak time and vacuum time.

As mentioned last month, this brief look at PAVs and VDOs isn’t an exhaustive list of the products available. Not all lab equipment manufacturers or suppliers are quick to share their product availability but mix designers, lab technicians and quality control teams are encouraged to check out the lab equipment advertised in these pages.