How to Perform Pressure Aging of New Mix in the Lab

BY AsphaltPro Staff

We know there are many benefits to testing mix designs in a lab setting prior to placing pavement on a roadway. One of the limitations is replicating the real world in the lab setting. Among the tools lab technicians use to replicate the real world is forcing “age” upon the fresh binder or new mix.

The American Association of State Highway and Transportation Officials (AASHTO), American Society of Testing Materials (ASTM) and European Standards (EN) are entities that regulate how testing is performed so everything is up to highest quality. Aging a binder in a lab falls under AASHTO R28, ASTM D6521 and EN 14769 test standards, and manufacturers of pressure aging vessels (PAVs) build their hardware and software to meet those standards. This sounds incredibly simple, but the fact of the matter is the OEMs have done the heavy lifting in creating the machines that will age the asphalt—so you don’t have to.

We don’t want to imply the manufacturers have dumbed it down, but when using a PAV, preparing a tower of pressure-aged samples for further testing is as easy as 1, 2, 3.

- Step one is to set the desired temperature and pressure using the device’s display/control panel.

- Step two is to insert the specimens.

- Step three is to press the start button and let the machine run the program.

Some manufacturers’ equipment will allow you to reverse steps one and two. The point is you set your parameters, put the specimens in, press “go” and let the machine do the rest of the work. The software within takes measurements and calculates information, providing that information to you via printouts, thumb drives, the ubiquitous cloud and so on.

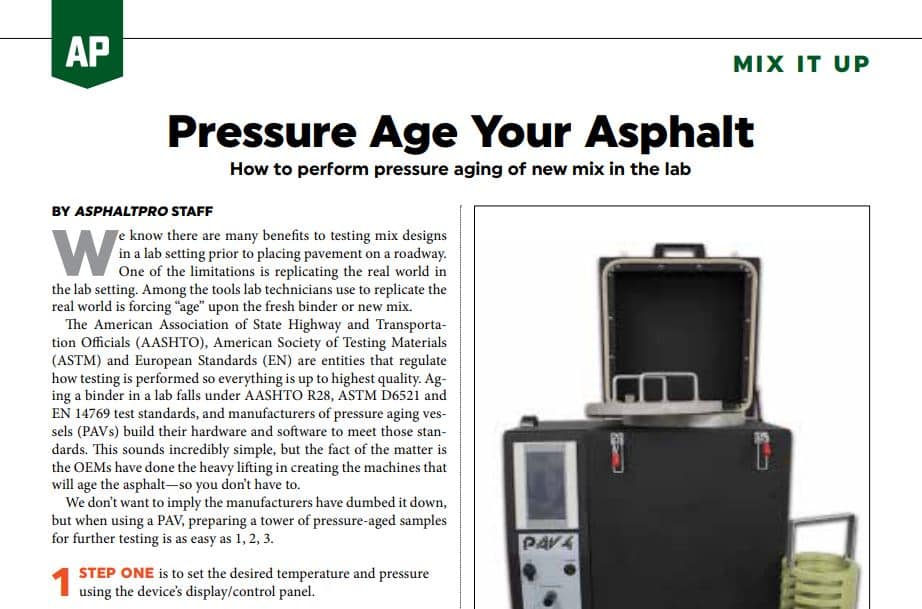

The pressure aging vessel from Applied Test Systems is the PAV4.

When the equipment has completed the aging process, the specimens are ready for testing in other devices. Depending on the test to be run, you may need them “still hot” or cooled. Depending on the test to be run, you may need them degassed, and that’s another back-to-basics article for another day.

Different PAV devices from different manufacturers offer similar operating pressure and temperature ranges, for obvious standardized testing reasons. For example:

The Applied Test Systems’ Pressure Aging Vessel (PAV4) has an operating pressure range of 2.10 ± 0.05 MPa (304 psi) and operating temperature range of Standard: 90°C, 100°C, and 110°C; Programmable from 50°C to 150°C. The system includes 10 AASHTO T 179 specimen pans and a solid, precision anodized aluminum specimen holder. Data acquisition features include time, temperature and pressure, and a USB port on the front of the unit makes data downloads (and software upgrades) convenient.

James Cox & Son’s New Generation Pressure Aging Vessel (CS-PAV1) has an operating pressure range of 2.1 ±0.1mPa and temperature range of 80° to 115°C, with resolution of 0.1°C. The system includes a set of ten specimen pans, a precision anodized aluminum sample holder with lifting handle, and a specimen handling tool. Additional pans can be ordered as necessary. Compressed air with a pressure of at least 350psi (2.4MPa) and a regulator must be user-provided.

The PV2600 from IPC Global has pressure monitored by transducer and controlled to 2.1 ± 0.1 MPa and selectable test temperatures from 80°C to 120°C, PID controlled to ±0.5°C. The system includes user friendly software that allows the operator to view in real time vessel temperature and pressure (set points and actual values) on a 6-inch, color, reclining, touch screen display.

This isn’t an exhaustive list. Check out the December product gallery coming up next month for some of the lab equipment and testing devices available to you in the marketplace.