Vogele WITOS Paving Docu Connects Job Site Apps

BY AsphaltPro Staff

WITOS Paving Docu from Vögele, Antioch, Tennessee, bridges the gap between its two existing job site applications: RoadScan, the non-contacting temperature-measurement system; and WITOS Paving Plus, the telematics solution for coordinating all processes from the mixing plant to the paving process in real time. The solution is aimed at contractors who want to record and analyze more than just paving temperature, but don’t need the full range of WITOS Paving Plus functions.

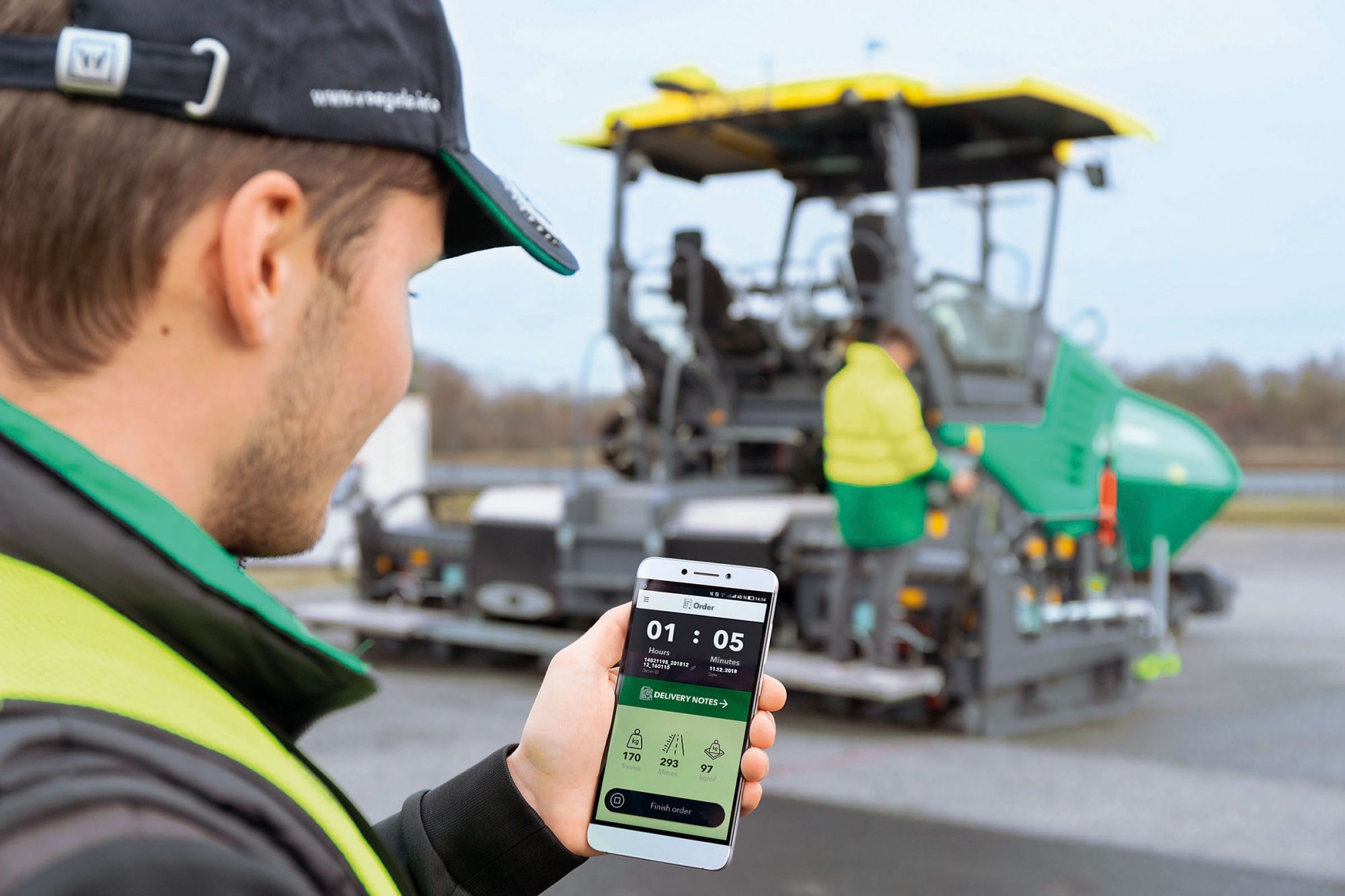

At a job site, foremen can use a special smartphone app (and paver operators the machine terminal) to initiate jobs in WITOS Paving Docu and record a wide array of additional paver and paving data, such as working width, paving speed, interruptions to paving and effective paving time. Delivery notes can also be scanned in using a QR code or entered manually, allowing paved areas, paved material quantities and areal densities to be calculated continuously. At the end of a day’s paving, job-site reports are sent automatically by e-mail to selected recipients. They include information on key job-site data and machine utilization.

The app and the paver are networked via WLAN, so information can be exchanged between the machine and the foreman’s smartphone even where there is no mobile phone connection. This way, both the foreman and paver operator know at all times how many tons of material have been paved on what surface area and in what areal density.

For contractors who want to plan their job sites by largely conventional methods, but document them digitally, WITOS Paving Docu offers the option of automating the recording and analysis of job-site data. All they have to do is install the corresponding app. The necessary hardware—the telematics module and the screed width measuring unit—is fitted directly in the paver. The app offers clear and intuitive menu navigation, so users can familiarize themselves with the application quickly even without specific prior knowledge or extensive training. For contractors, this greatly increases the efficiency of job-site documentation processes without requiring lengthy introductory phases.

The application is designed to function even in rural areas with no mobile coverage. The paver creates a WLAN network with a range of about 164 feet (50 m) and acts as the server on the job site.

The full version of WITOS Paving Plus, Vögele’s software-based process management solution, networks everyone involved in the process, from the mixing plant to the paver operator, and comprises five modules. Job site planning (Control), provision of mix (Materials), mix transport (Transport), paving of asphalt (JobSite) and the subsequent analysis of processes (Analysis); therefore, can all be managed by a single system in real time.

For more information, contact Matt Graves at matt.graves@wirtgen-group.com or visit www.wirtgen-group.com/america.