Tacoma Builds Award-Winning Greenroad

BY AsphaltPro Staff

To learn more about checking in-place air voids, check out this accompanying article, “How to Check In-Place Air Voids.”

North America has a new, high-scoring environmentally sound project thanks to porous asphalt paving design in the City of Tacoma, Washington. The Greenroads Foundation, headquartered in Washington, manages a third-party certification process that assesses the sustainability of transportation projects using the Greenroads Rating System. For 2020, the foundation has awarded the City of Tacoma’s East 40th Street Green Infrastructure Project the Greenroads Silver Certification.

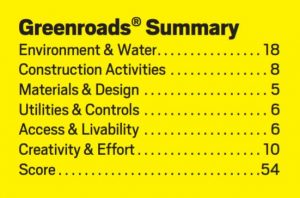

The project earned 54 points and met all project requirements to become the highest-scoring Greenroads project in the world. The Sandy Forks Road project in Raleigh, North Carolina, which you can read about here, had held this distinction since November 2017.

The East 40th Street Green Infrastructure Project reduces neighborhood flooding, enhances safety and increases accessibility, replaces underground utilities including water mains and sanitary sewers, and improves water quality by 99.8 percent for 39.1 acres in the First Creek, Lower Puyallup watershed. Localized flooding previously happened along this corridor because it is a low point in the East Tacoma neighborhood.

The East 40th Street Green Infrastructure Project reduces neighborhood flooding, enhances safety and increases accessibility, replaces underground utilities including water mains and sanitary sewers, and improves water quality by 99.8 percent for 39.1 acres in the First Creek, Lower Puyallup watershed. Localized flooding previously happened along this corridor because it is a low point in the East Tacoma neighborhood.

Let’s take a look at the project’s design, execution and success. It began in 2017, when the City of Tacoma’s environmental services division let the job to prime contractor Northwest Cascade Inc. and paving subcontractor Miles Resources LLC, Puyallup, Washington, to rebuild and pave a porous asphalt on East 40th Street.

Pat McBride is the estimator/project manager for Miles Resources, and provided details of the mixes and design that made the new pavement structure possible.

“In Western Washington, the projects requiring porous hot-mix asphalt (PHMA) are becoming more and more common,” McBride explained. “With this trend, the City of Tacoma, several asphalt paving contractors, asphalt designers and the Washington Asphalt Paving Association (WAPA) have been constantly working to create higher quality porous asphalt designs. This project was one of the initial projects in Western Washington using designs from this group’s efforts and yielded outstanding results that have helped improve PHMA and asphalt-treated permeable base (ATPB) design and placement throughout Western Washington.”

McBride explained that the project first required the team demolish the existing hardscapes and landscaping, replacing them with environmentally driven materials that would allow stormwater to infiltrate the new roadway, new landscaping and new sidewalks with the intention of furthering the advancement of clean stormwater systems in lieu of further adding to the city’s existing stormwater systems.

Replacement meant paving with environmentally sound asphalt and best practices to ensure a long-lasting pavement structure that won’t require frequent maintenance.

Miles Resources paved side by side to eliminate the cold joint.

“Miles Resources executed the 2,224 tons of PHMA and ATPB paving in two lifts over the course of two days,” McBride said. “The goal was to pave the roadway with virtually no joints, as failures tend to occur in these types of projects at cold joints.”

He explained the paving team accomplished this using three pavers; two of which worked side-by-side to place asphalt down the two-lane road while a third pulled the side streets in. “This was not only aesthetically pleasing, but created a uniform looking roadway with a smooth, bump-free surface,” McBride said.

The porous pavement structure is as follows:

- A 6-inch section of filter sand

- A filter fabric on top of the filter sand

- A 4-inch lift of permeable ballast rock

- A 3-inch lift of asphalt treated base

- A 2-inch top lift of aramid fiber-reinforced CI ½-inch PG70-22ER PHMA

“Both the ATPB and PHMA are designed for an equivalent single axle load rating of 0.3 to 3.0 (millions) and used 0.5 percent of Evotherm M1 anti-stripping in the PG70-22ER binder,” McBride said. “The designed air voids for the ATPB were 27 percent and for the PHMA were 19.7 percent.”

McBride shared that it can initially be difficult for inspectors and some agencies to grasp that the paving team isn’t shooting for normal compaction ranges seen with standard asphalt paving. The densities of 93 percent and higher would destroy this system.

The project features a 16-foot shared space separated from the roadway by bioswales that filter rainwater while increasing the route’s safety and aesthetics. Image by Aaron Copado, courtesy of the City of Tacoma

“You have to picture aggregates in porous asphalt as a bunch of marbles stacking up next to each other,” McBride explained. This “stacking” creates the desired voids in mineral aggregates (VMA), which makes the structure porous. “The necessary voids will cause a much lower compaction result from a nuclear gauge than a standard asphalt mix but in fact will be fully compacted.

“For example,” he continued, “on this project our top lift of half-inch porous HMA was designed for 19.7 percent air voids (VA), so this would be designed for 80.3 percent compaction. The base lift of Asphalt Treated Porous Base was designed for 27 percent VA, so we would be shooting for 73 percent compaction. Because there are primarily only a few sizes of coarse aggregate in porous asphalt, the mix compacts quite readily and achieving the design levels of compaction isn’t an issue.”

After each lift was placed, the Construction Testing Laboratories, located in Puyallup, Washington, took samples for infiltration testing. “The project specifications called for infiltration rates of a minimum rate of 100 inches per hour,” McBride said. “We achieved an average of 3,000 inches per hour on the ATPB and 600 inches per hour on the PHMA.”

He explained that the infiltration testing was performed, in place, per ASTM C1701 Standard Test Method for Infiltration Rate of In Place Pervious Concrete. While that might sound a little strange, because the test method was originally designed to test pervious concrete pavements, it’s now often specified to test porous asphalt as well. “A 12-inch-diameter pipe is sealed to the pavement surface with plumbers putty and 40 pounds of water is timed being poured into the pipe and down into the pavement,” he explained. (See article “How to Check In-place Air Voids.”)

The new road features narrower lanes than before to improve safety and reduce speeding, and was built with permeable pavement to allow stormwater to filter through the soil. This reduces stormwater flow and helps filter pollution from the water before it reenters the First Creek ecosystem, alleviating 38 percent of the site runoff for downstream impacts.

“The project is a green gem for transportation in the State of Washington,” said Dr. Jeralee Anderson, CEO of Greenroads International. “We are thrilled for Tacoma’s team and so proud of their leadership and commitment to environmental sustainability.”

This is the fifth certified Greenroads project in Tacoma, reinforcing the city’s commitment to environmental policy leadership. Tacoma is a Greenroads member and was the first to adopt a resolution establishing the city as a “Green Roads Community” by creating its roads and infrastructure as “models of environmental, economic and social stewardship,” according to Resolution 38945.

The $4.5 million project was funded with a grant from the Washington State Department of Ecology, the City of Tacoma’s Public Works’ voter approved Streets Initiative Fund, the Environmental Services Department’s Surface Water Fund, and the Tacoma Water Bond Fund.

Numerous unique partnerships across organizations and the community helped to create a valuable asset for the Eastside Tacoma Neighborhood. The construction and design of the project was created by a partnership between the City of Tacoma’s Environmental Services, Public Works, and Public Utilities Departments, along with the Washington Department of Ecology, KPG, GeoDesign, Northwest Cascade Inc., Totem Electric, Miles Resources, Silver Streak Inc., AESI, and Watershed Environmental Solutions LLC.

The project received the Pacific Northwest Clean Water Association’s “2018 Innovative Stormwater Project Award” and Washington Asphalt Pavement Association’s “2019 Special Innovative Pavement for Western WA.” It also placed third in the National Association of Flood Stormwater Management Agencies’ “2018 Green Infrastructure Award” for cities with medium and large populations.

McBride is proud of more than the awards. The project offered Miles Resources an opportunity to test best practices and prove the environmental benefits of asphalt. “Installing the porous asphalt treated base allowed for increased infiltration as opposed to putting directly on ballast or choker,” he said. “The use of aramid fibers alleviated drain down concerns and helped keep the binder on the rocks as well as strengthen the overall asphalt. The use of multiple pavers to eliminate joints will help extend the life of the asphalt.”

In the end, the project was recognized not just for its environmental stewardship, but also for its special and innovative use of HMA.

There are currently more than 130 projects registered for the Greenroads Project Rating Program in 11 states and 8 countries valued at more than $32 billion USD. Washington State has the most certified Greenroads in the world, and the City of Tacoma’s project is the 29th to certify in the state since the program began in 2011.

Established in 2010, Greenroads Foundation is an independent 501(c)(3) non-profit corporation which advances sustainability education and initiatives for transportation infrastructure. As the developer of the Greenroads Rating System, the foundation manages the certification process for sustainable transportation development projects in the U.S. and internationally.

Extra Parts of the Puzzle

A 16-foot-wide shared-use path was built along the new roadway from East McKinley Avenue to Portland Avenue East, creating a safe connection for pedestrians and cyclists traveling to nearby schools or accessing the new Pipeline Trail. Thirteen biofiltration swales, or sloped channels designed to capture and filter stormwater runoff, were installed between the roadway and the path. Over 150 trees were planted within these bioswales to create a safety buffer.

A 16-foot-wide shared-use path was built along the new roadway from East McKinley Avenue to Portland Avenue East, creating a safe connection for pedestrians and cyclists traveling to nearby schools or accessing the new Pipeline Trail. Thirteen biofiltration swales, or sloped channels designed to capture and filter stormwater runoff, were installed between the roadway and the path. Over 150 trees were planted within these bioswales to create a safety buffer.

The project team also partnered with local eastside elementary and high schools to beautify the new shared-use path. Students from Lister, Lincoln, Stewart and First Creek schools used a superhydrophobic coating to paint poetry into the pavement.

“The project created connections to other neighborhoods and provided access to multi-use centers in the city. Not only was mobility improved, but the project’s attributes addressed multiple stormwater and transportation issues facing this particular neighborhood,” said Olivia Mathison, associate engineer with the City of Tacoma’s Environmental Services Department.