Road Dryer’s RD-1200XT

BY AsphaltPro Staff

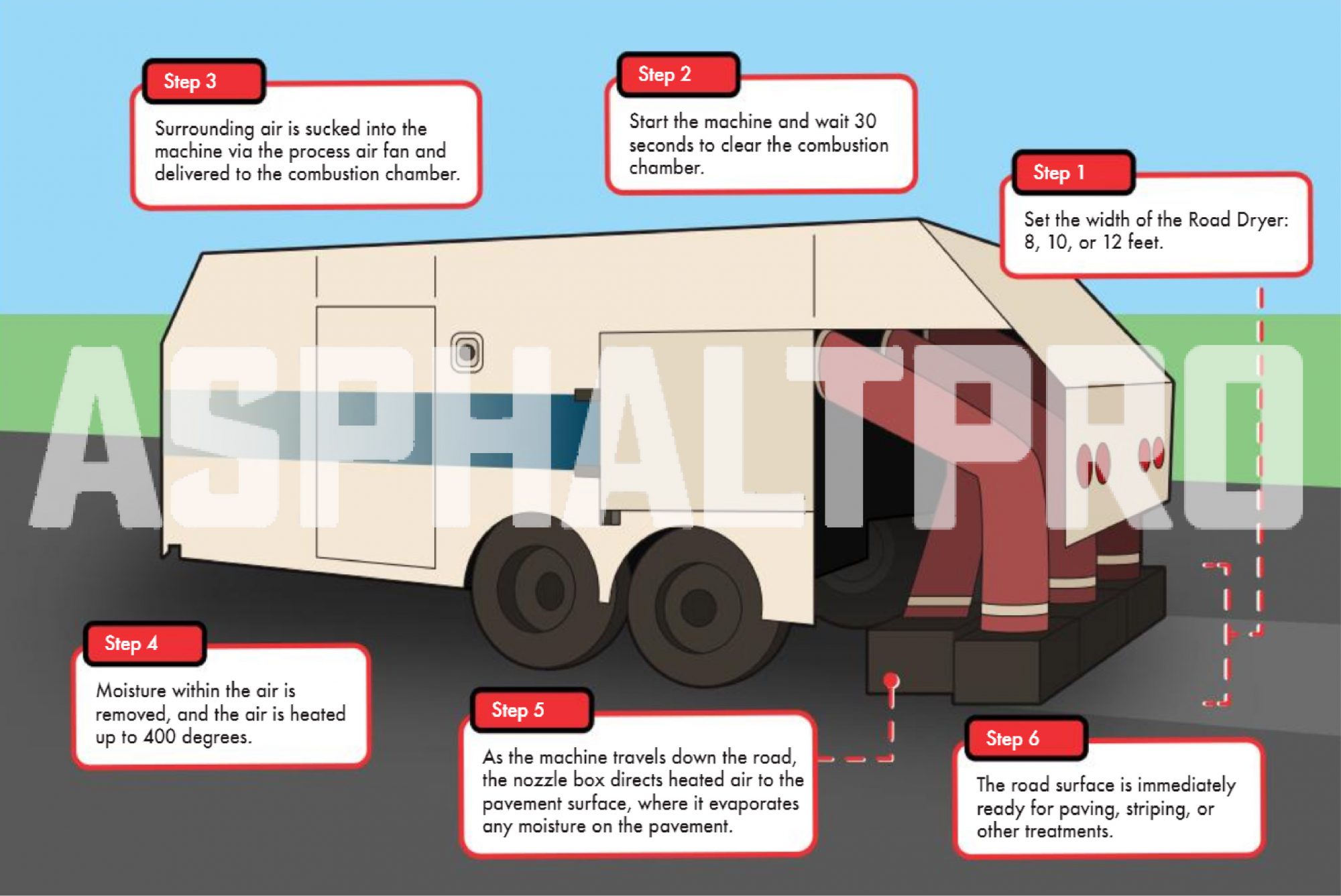

From rainy weather to controlling silica dust with water, the asphalt paving crew may have to dry a pavement surface with equipment before work can commence. That’s why Road Dryer LLC, Greenville, South Carolina, has developed its RD-1200XT road dryer: to minimize delays from wet conditions and make it easier for contractors and agencies to meet timetables. Here’s how it works.

Upon arrival to the job site, the tractor trailer- or truck-mounted RD-1200XT will first need to be adjusted for the project’s parameters. The operator will open the side nozzle door, release the safety, and lower the nozzles into place. The standard width is 8 feet, but the operator can fold out two separate nozzle wings to dry widths of 10 and 12 feet.

From the control panel on the side of the machine nearest the trailer or truck, the operator will start the machine. Prior to igniting the burner, a short 30-second purge will clear the combustion chamber of any possible unburnt gases. Surrounding air is sucked into the air heater via the air inlet to the process air fan, driven by the diesel engine. Air is then blown into the combustion chamber, where it is heated up to 400 degrees and the moisture is removed. The heating process takes approximately three minutes from the time the burner is lit.

The machine is then ready to be pulled down the road at speeds between 25 and 50 feet per minute, directly behind the milling machine or hydro-blaster, or directly ahead of the paver. As the RD-1200XT travels down the road, the nozzle box on the back of the machine rides above the surface of the roadway on a set of wheels. The six nozzles contained in the box direct the heated air ahead of, behind, and to the sides of the machine to allow for longer surface exposure. The design of the nozzle box controls the air flow to the roadway to allow for usage in construction lanes next to live traffic.

The dry, heated air immediately evaporates the moisture on the pavement, leaving the road surface ready for paving, striping or other treatments. When the required surface has been dried, the operator will fold in the nozzle wings, raise the nozzles until the safety latch locks, and close the nozzle doors before driving the RD-1200XT to the next job.

For more information, contact Road Dryer at (864) 272-2988 or info@roaddryer.com.