PSS’ RoadQuake® RAPTOR™

BY AsphaltPro Staff

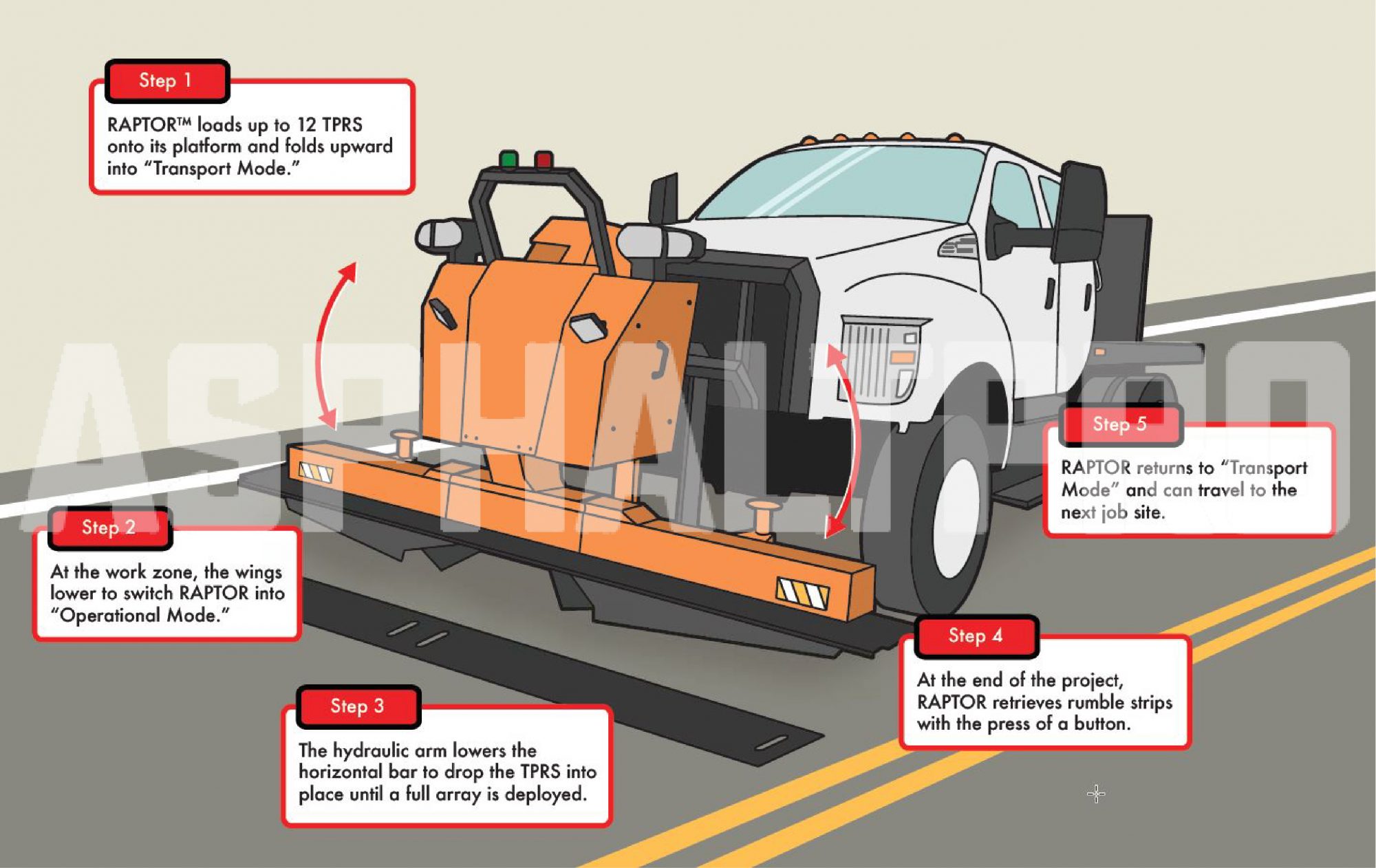

Keeping workers out of live traffic is a fundamental part of work zone safety. To that end, the team at PSS, Cleveland, has developed the RoadQuake® RAPTOR™ Rumble Strip Handling Machine that fits on the front of a work truck to transport, deploy, realign and retrieve RoadQuake 2F Temporary Portable Rumble Strips (TPRS). Here’s how it works.

Introduced in 2009, RoadQuake TPRS alert drivers to changing road conditions. The strips conform to the surface of the road and were designed for use in short duration work zones. RAPTOR is the latest innovation to PSS’s line of rumble strip handling equipment. The machine, affixed to the front of a work truck, picks up the TPRS with a magnetic bar and sets the strip on the tray of the apparatus. Up to 12 TPRS are loaded, and the two wings of the RAPTOR platform partially fold upward into “Transport Mode.”

At the work zone, the truck driver uses a remote control from the safety of the cab to lower the wings of the machine into “Operational Mode.” He then presses a button to activate the RAPTOR’s magnetic bar to retrieve the TPRS; the hydraulic arm lifts and aligns the TPRS on the lane, releasing it in place. The driver moves forward and repeats the process, with no manual stress injuries to himself.

If a rumble strip is skewed by traffic during the project, the driver can bring the truck to the strip and press a button to have the RAPTOR realign the TPRS. Again, no workers have to step into live traffic.

When the project is complete, RAPTOR retrieves each rumble strip and returns it to the tray. When all strips have been collected, the machine returns to “Transport Mode” and moves on to the next job.

For more information, contact Dave McKee at (216) 403-0898 or david.mckee@pss-innovations.com.