Hitek’s Pavijet MG7 MiniPaver

BY AsphaltPro Staff

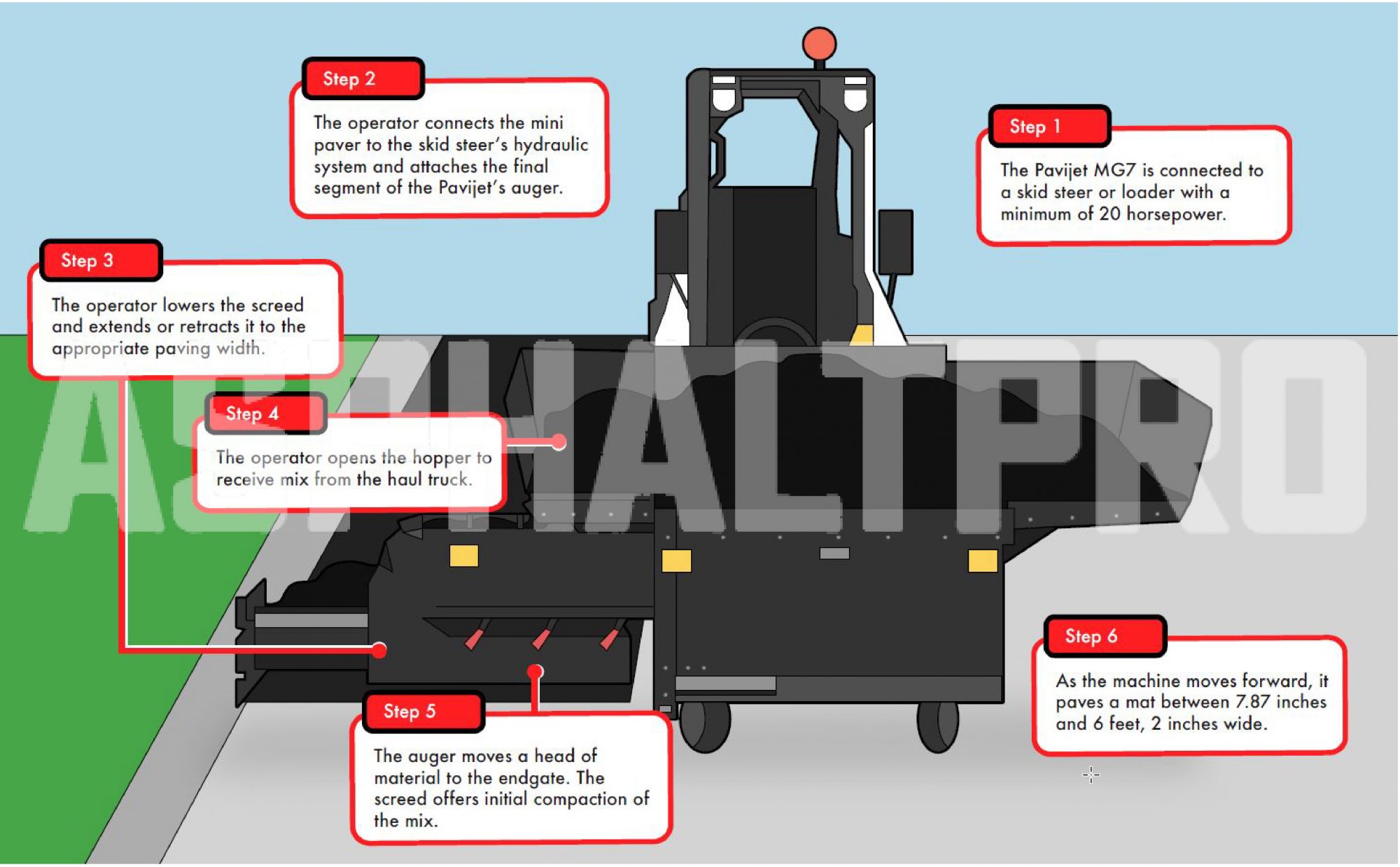

The Pavijet MG7 from Hitek Equipment Inc., Kenosha, Wisconsin, is a mini paver that can be used for road widening, shoulder work, and maintenance and repair work. It can also be used to pave cycling paths, sidewalks and other narrow paving jobs. Here’s how it works.

The Pavijet MG7 connects to a skid steer or loader with at least 20 horsepower. The operator then connects the Pavijet to the skid steer’s hydraulic system and attaches the final segment of the machine-wide auger by hand.

From the cab of the skid steer, the operator then lowers the extendable screed with controls onboard or by a small radio control system. He can use the radio control system from outside the skid steer to dial in the precise paving width–anything from 7.87 inches to 6 feet, 2 inches–from a better vantage point. All control of the machine uses the skid steer’s hydraulic system.

Next, the operator unfolds the hopper. A haul truck delivers material, such as gravel, sand, stones or hot-mix asphalt, directly to the 1.8 cubic yard hopper.

The hydraulically driven auger, which extends the width of the machine, pushes material out to the endgate. The screed provides initial compaction of the mix as it’s laid at depths from 1.97 inches below grade to 9.84 inches above grade behind the mini paver.

As the machine paves, the operator can fold up the hopper to move more mix to the auger box. He or she can also retract the screed as needed to navigate around obstacles such as signs and trees.

For more information, contact Shane Sommers at (262) 842-1700 or shane@minipaver.com.