Maxam’s Safe-Sampler™

BY AsphaltPro Staff

If you need to take liquid asphalt cement (AC) samples from your 4-inch or 6-inch line that feeds liquid AC to your mixer, the engineers at Maxam Equipment, Kansas City, Mo., have developed a sampling device to assist you. This in-line capture features an enclosed sampling system to dispense the asphalt into quart or gallon containers without exposing workers to hot liquid. Here’s how it works.

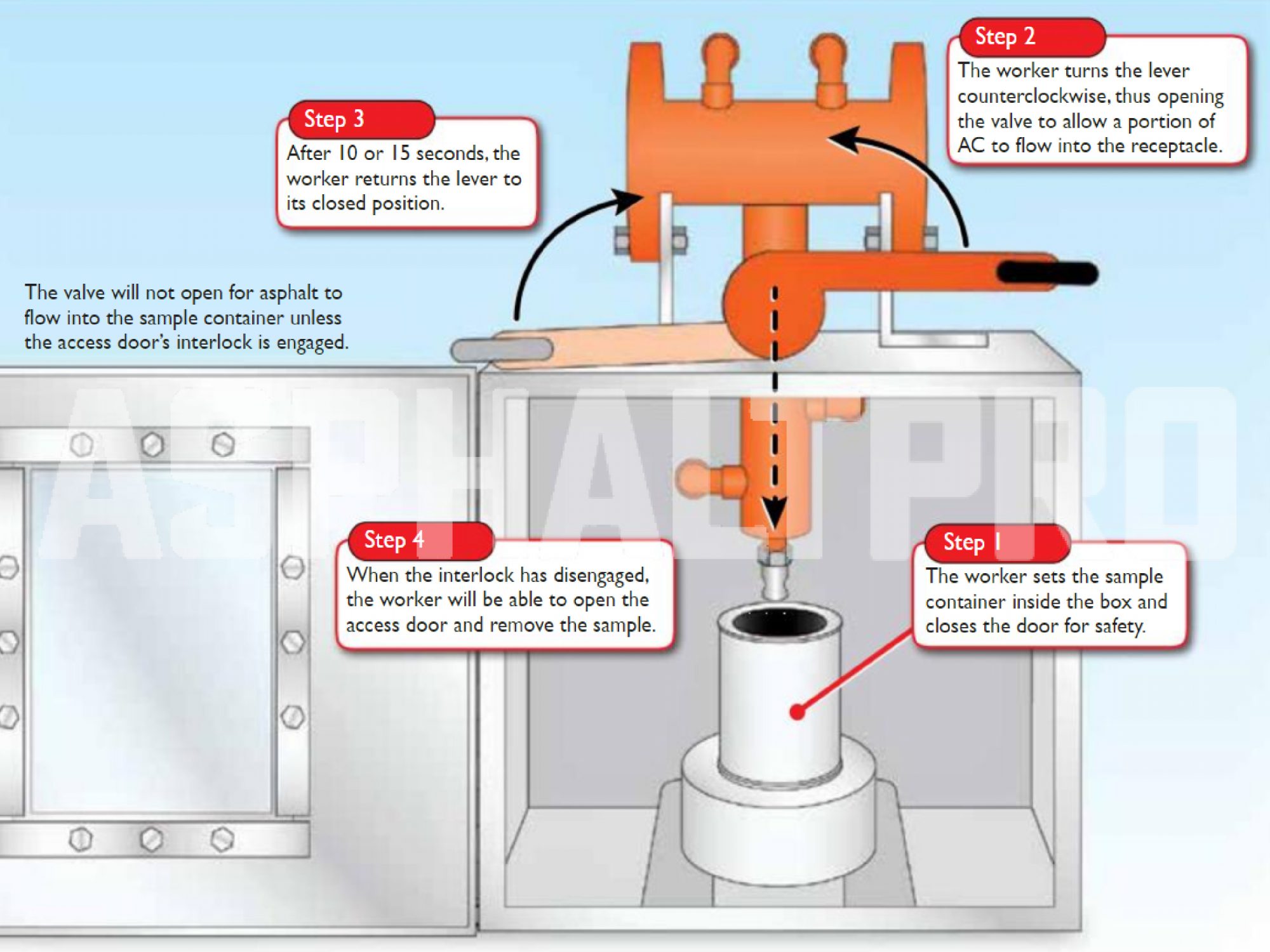

The mechanic installs the Maxam Safe-Sampler™ in the existing asphalt line at the plant. Asphalt flows through the heated spool. When a worker needs to take an asphalt sample, he or she places the receptacle inside the box beneath the valve.

The worker closes and latches the door on the front of the box. He then rotates the lever counterclockwise to no more than a 6 o’clock position to begin the sampling process. The sampling will not begin unless the access door’s interlock is engaged.

The hot-oil-heated piping, valve and spout allow liquid AC to flow without plugging to the sampling container within the box. The worker views the flow through the high-temperature glass on the front door. The flow of AC continues through the line during the sampling, with just a minimal sample amount deflected to the sampling valve.

When the container is filled—approximately 10 to 20 seconds for a quart container depending on the size of the line—the worker rotates the lever back up to close the valve, stopping the flow of AC through the spout. The flow continues normally through the line.

For more information, contact Maxam at 816-241-7380 or visit www.maxamequipment.com.