Look at What’s New for Mix Production

BY AsphaltPro Staff

Quality starts way back at the quarry and refinery. It continues at the asphalt mix plant. For this edition focused on quality control and best lab practices, it only makes sense that we present some of the latest and greatest offerings for the production of a mix that’s on spec.

Asphalt Drum Mixers Inc.

ADM offers heavy-duty drag conveyors with material transport ratings up to 500 TPH.

Asphalt Drum Mixers Inc. (ADM), Huntertown, Indiana, offers a full line of drag slat conveyors for all of its asphalt plants, or to be paired with plants from other asphalt plant manufacturers. The conveyors are designed to handle material transport ratings as high as 500 tons per hour (TPH) with reinforced weld-on slats and chrome carbide wear liners on the slat floor and along the sidewalls. ADM designed the conveyors with a segmented sprocket design, which allows for easy access to the stairway, handrail and maintenance platforms. Full-length hinged steel casing covers come standard on the drag slat conveyors and optional blue-smoke recovery systems mount on the conveyor to reduce emissions from silo tops.

For more information, contact Mike Devine at (260) 637-5729.

AMETEK

AMETEK, Brookfield, Middleboro, Massachusetts, offers the DV2TRV Viscometer to measure the viscosity of highway asphalt binders at mixing and compacting temperatures. It uses AMETEK Brookfield’s Thermosel System as defined by the Strategic Highway Research Program (SHRP).

The features include:

• Adheres to ASTM D4402;

• Ensures asphalt pumpability; and

• Provides variable temperature and shear rate capability for complete viscosity profiles.

For more information, contact (508) 946-6200.

Ammann

The ABP HRT from Ammann is designed to incorporate large percentages of RAP in mix designs.

The Ammann ABP HRT (High Recycling Technology) asphalt-mixing plant is designed for asphalt manufacturers who need to incorporate large proportions of recycled asphalt (RAP) without sacrificing production capacity and quality. The HRT is a “2-in-1” plant, featuring both a warm and cold recycling system that can be used simultaneously. The plant became available in the North American market about a year ago. It is manufactured by Ammann, a family owned, Swiss-based company.

There are two warm recycling systems to choose from: A conventional concurrent flow dryer for RAP additions of up to 60 percent; and the RAH100, from which 100 percent recycled materials can be used. Foamed bitumen, pigments and other additives can be used.

The most striking visual difference between the HRT and traditional plants is the vertical stacking of the RAP-bearing components. This configuration is designed to reduce wear and sticking and shortens the travel distance of hot RAP material.

Astec Industries

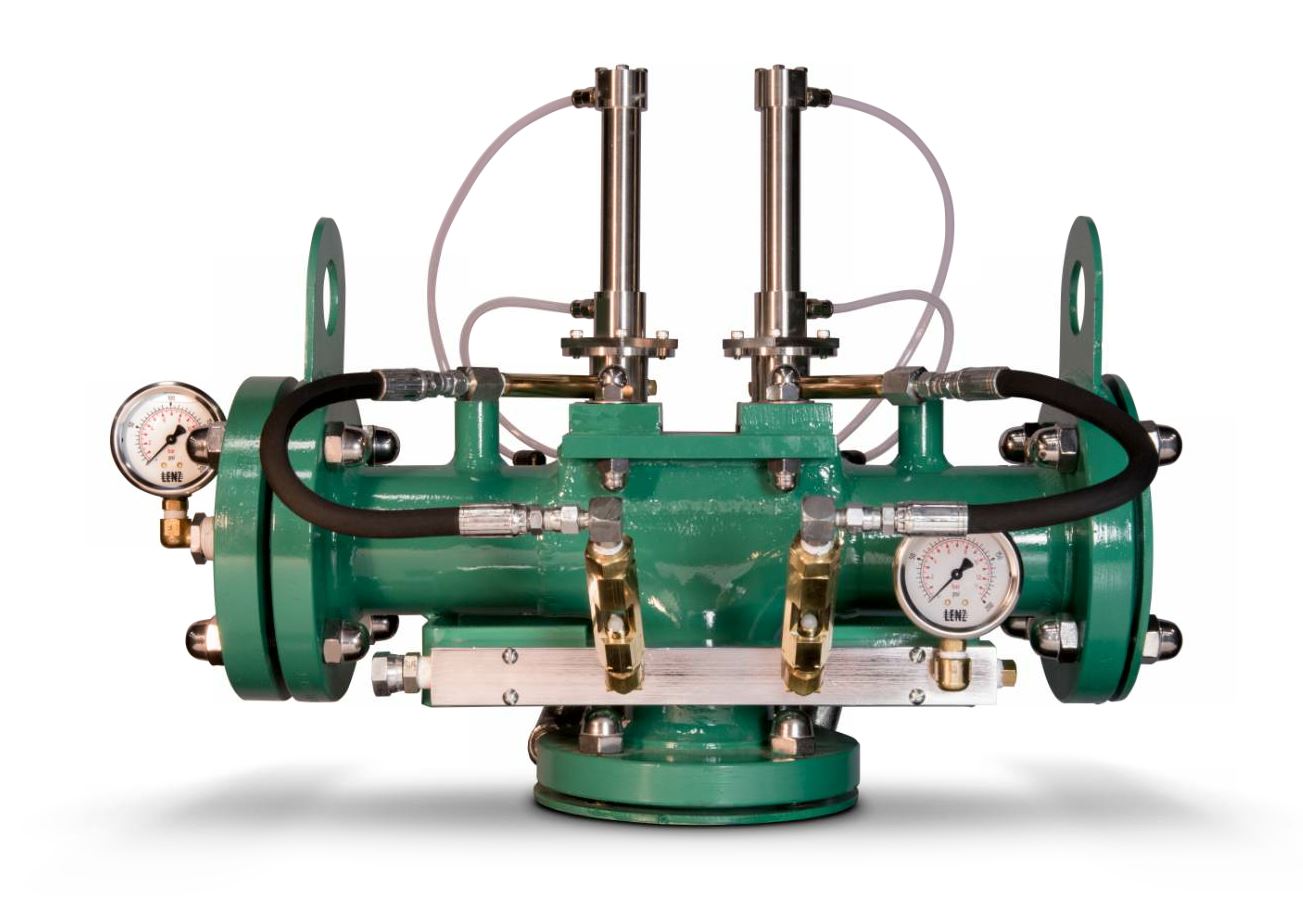

The Generation 3 from Astec uses a flow splitter plate to force liquid AC to encounter the water spray nozzles within the system.

Astec Industries, Chattanooga, Tennessee, released the Generation 2 warm-mix system December 2017 to allow producers to make WMA mix designs without chemical additives. The Gen3 apparatus is installed inline. It uses a flow splitter plate to ensure the heated AC encounters both water spray nozzles in the system. As the liquid AC enters the Gen3 manifold, it is directed above the splitter plate adjacent to two water injection valves. Electric over air solenoids open and close self-cleaning water valves to inject water. As water flashes to steam and mixes with liquid AC, it foams and expands through an orifice plate and into the mixing device.

For more information, contact Astec Parts at (800) 251-6042.

Butler-Justice Inc.

The X-VOCS asphalt plant odor control system from Butler-Justice was introduced in 2017.

Blue Smoke Control, a division of Butler-Justice Inc., Anaheim, California, offers the X-VOCS System, which features proprietary technology designed to remove odors and VOCs such as Hydrogen Sulfide (H2S) from the hot-mix asphalt process. Introduced in late 2017, the system is best applied to existing or new installations where long-term odor and VOC control/containment is important. The X-VOCS incorporates a five-stage filtration system. In the first three stages, a series of filters remove over 95 percent of target particulates down to 0.3 microns. In the final two stages, carbon filtration beds remove remaining odors and volatiles, according to the manufacturer.

Maximum emissions control can be achieved when paired with the company’s patented Blue Smoke Control Collector, which is designed to target and eliminate “blue smoke.” Those systems are operating in hundreds of plants worldwide.

For more information, contact Mike Butler at (714) 696-7599.

IPC Global

IPC Global’s Pavelab50 PaveAnalyzer is an automatic asphalt analyzer designed for the separation and extraction of bitumen, filler and aggregates from asphalt mixtures by closed-system solvent extraction. Fully compliant with the new ASTM D8159-2018 Automated Extraction of Asphalt and EN 12697-1 and benefiting from the latest environmentally friendly technologies, the Pavelab50 PaveAnalyzer makes the extraction process safer, faster and easier with almost zero emissions coming from the extraction process, according to the manufacturer. The totally integrated system includes a washing and extraction chamber, high speed centrifuge, solvent recycler, aggregate dryer and balance all-in-one unit minimizing the footprint, improving safety, reducing variability, and saving laboratory and operator time, according to the manufacturer.

For more information, contact ipcglobalsales@controls-group.com or info@controls-usa.com.

KPI-JCI

The GT440 mobile horizontal shaft impactor from KPI-JCI and Astec Mobile Screens offers patent-pending hybrid technology.

KPI-JCI and Astec Mobile Screens, Yankton, South Dakota, launched their latest patent-pending hybrid technology in their GT440 mobile horizontal shaft impactor (HSI) at ConExpo in March 2017. This hybrid unit offers rugged performance with environmentally-friendly features. While operating in line power, the GT440 has significantly lower operating costs, reduced permitting, reduced noise levels, creates no engine emissions, has the ability to run indoors and does not require refueling.

All of the components are included onboard to allow operations to easily switch the power supply.

“This hybrid technology is truly revolutionary, our customers can benefit from electric power without sacrificing the convenience of a diesel power unit, all at the push of a button,” said Stephen Whyte, product manager for KPI-JCI and Astec Mobile Screens.

For more information, visit https://www.kpijci.com/equipment/track-mount/andreas-hsi-plants/.

Leica Geosystems

Leica Geosystems, part of Hexagon, Heerbrugg, Switzerlaand, announced in June, its new Leica Aibot. The latest unmanned aerial vehicle (UAV) system is based on DJI’s aerial platform, the M600 Pro, to acquire mobile 3D mapping data. The technology is designed to allow users to get a complete data set with a user-friendly and innovative interface. Leica Geosystems software suite supports the new UAV workflows. It uses Leica Infinity for point cloud, digital surface model and orthophoto generation.

For more information, visit https://leica-geosystems.com.

Libra Systems Inc.

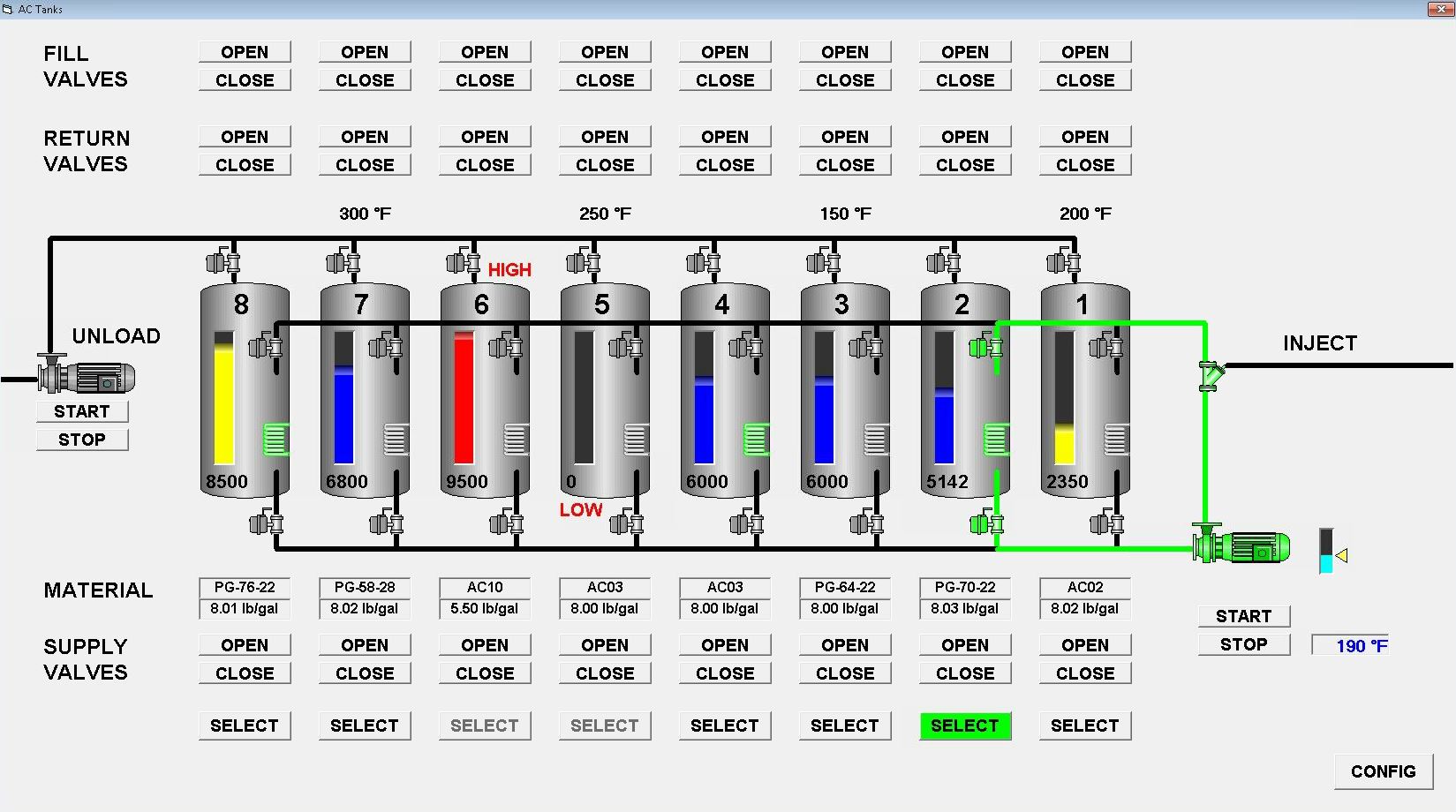

This screen shot shows the new version of Libra’s Automatic AC Tank Switching Module.

Libra Systems Inc., Harleysville, Pennsylvania, has released a new version of its Automatic AC Tank Switching Module, available for the PlantWise Drum Mix Control System. The enhanced module controls all fill, return and supply valves, as well as the AC pump and truck unloading. Tank levels are also monitored, including critical limits. Dynamic, color-coded graphics provide at-a-glance status pertaining to valve changes, material flow, tank levels, temperatures, interlocks and any alarm conditions that require the operator’s attention. Manual control of heaters, agitators, etc. can be turned on and off through the software. The Automatic AC Tank Switching Module is fully integrated with the PlantWise automatic blending process, including material use totals and the capability to control the entire plant without manual buttons.

For more information, contact Greg Fleisch at (215) 256-1700 x123.

Pine Test Equipment Inc.

The Rotary Asphalt Wheel Tester from Pine has more than 14 years of proven performance with the City of Los Angeles.

The Rotary Asphalt Wheel Tester (RAWT) by Pine Test Equipment Inc. was designed to determine the rutting performance of all HMA mix types. The accuracy and predictability of this accelerated test method remained ambiguous until the City of Los Angeles shared the results of 14 years of use and 15,000+ SGC rut wheel tests of many different HMA mix types. Now an integral part of the City of LA’s Pavement Preservation program, the results were featured in the September 2016 edition of AsphaltPro. Independent research conducted by Dr. Hussain Bahia of the Modified Asphalt Research Center (University of Wisconsin Madison) on the speed, accuracy and repeatability of the new rutting test method was presented at the June 2018 ASTM meeting in San Diego. The short test time allows for expedited quality control and acceptance.

For more information, contact Dave Savage at (724) 458-6393.

Stansteel

The Accu-Shear® from Stansteel/Hotmix Parts is installed in the asphalt injection line prior to the plant mixing zone.

The Accu-Shear® from Stansteel/Hotmix Parts, Louisville, Kentucky, is designed for multiple liquid additives and features advanced in-line water foaming of liquid asphalt cement (AC). The shearing process promotes total blending and homogenized flow for warm-mix asphalt (WMA) production. The Accu-Shear is also engineered for in-line blending of rejuvenators, latex, emulsions and most liquid chemicals on the market today with the optional four-port additive manifold.

For more information, contact Rick Rees at (800) 826-0223.

TransTech Systems Inc.

You can let the plant know how the mix is performing in real time with a non-nuclear pavement density gauge from TransTech.

The flagship product from TransTech Systems Inc., Latham, New York, the Pavement Quality Indicator (PQI), is what put the company on the map in 1998. The PQI is the non-nuclear pavement density gauge offering precise pavement density and moisture measurement in 3 seconds, according to the manufacturer. With the PQI, you don’t have the hassle of regulatory training and certifications. There is no radiation threat with the product, which means after a day of work just place it in your truck and you’re done. Help TransTech celebrate 20 years of non-nuclear density technology.

For more information, call (800) 724-6306 or visit www.transtechsys.com.

Troxler

The Troxler Moisture Measurement System (MMS™) (Model 3630) is a real-time method of moisture measurement for quality-oriented asphalt plants. It launched in May 2017 to provide accurate moisture content through a noncontact “scan” of combined virgin aggregate. This helps plants more precisely control binder addition, resulting in cost savings and a better quality product. It also allows operators to better manage the burner temperature during drying to enhance product quality and save energy/reduce emissions.

The MMS measures virgin aggregate on an inclined conveyor belt and provides a continuous moisture content reading. Measurements are displayed in a plant’s control room or transmitted to its control system. This data, when used in conjunction with weigh bridge data, allows the plant to make asphalt more like the mix design.

For more information, contact Miguel DeJesus at (919) 719-1836.

Viking Pump

Viking Pump offers electrically heated asphalt pumps to complement its industry leading asphalt pumps fitted with integral heating jackets. Introduced in 2015, electric heating provides an alternative for heating asphalt and bitumen.

Electric heating offers a number of advantages over steam, heat transfer oils or external electric heat tracing, including:

• Lower installation costs in remote locations when steam or hot oil is not available or requires long piping runs.

• Reduced environmental costs by eliminating hot oil leaks.

• Reduced energy costs with heat source in pump vs. external heat tracing.

• Simplified service by eliminating hot oil or steam pipe connections.

• Improved safety by eliminating hot oil or steam piping leaks.

Viking also offers a simple and effective temperature control system. It includes a thermocouple with thermowell for mounting in the bracket port, and a controller which powers all heat cartridges on one pump.

For more information, contact Gus Purcell at (910) 276-4343.