Kokosing Saves with Lone Worker Solution

BY AsphaltPro Staff

Kokosing Materials Inc., a sister company of Kokosing Construction Co. Inc., Fredericktown, Ohio, has long been concerned about employees working at its facilities alone, whether that takes the form of a loader operator left alone pushing up millings, the plant operator loading out the rest of the mix, the quality control tech finishing up a test, or the terminal operator transferring liquid.

“What if someone has a medical emergency?” said Chuck Mull, corporate environmental manager at Kokosing. It wouldn’t be the first time that happened. A few years back, one of Kokosing’s loader operators had a cardiac event. “Thankfully, there were guys in the shop close by, but if he had been alone, we could have had a big issue.”

The company tried to enforce having two people on site at all times, but found it was a hard practice to keep up when the season got busy. With all facilities operating at max and multiple night shifts a week, personnel would get pretty slim. “It’s a big challenge for asphalt companies, since you’re usually running with just a plant operator, loader operator and ground guy,” Mull said. It doesn’t give much leeway for a two-man rule.

That’s why Kokosing’s safety team invested in lone worker safety devices from Blackline Safety Corp., Calgary, Canada. It’s an investment that has earned the company the National Asphalt Pavement Association’s 2020 Asphalt Operations Safety Innovation Award. Kokosing has previously been recognized with NAPA’s 2018 Asphalt Operations Safety Innovation Award for its lockout/tag out app.

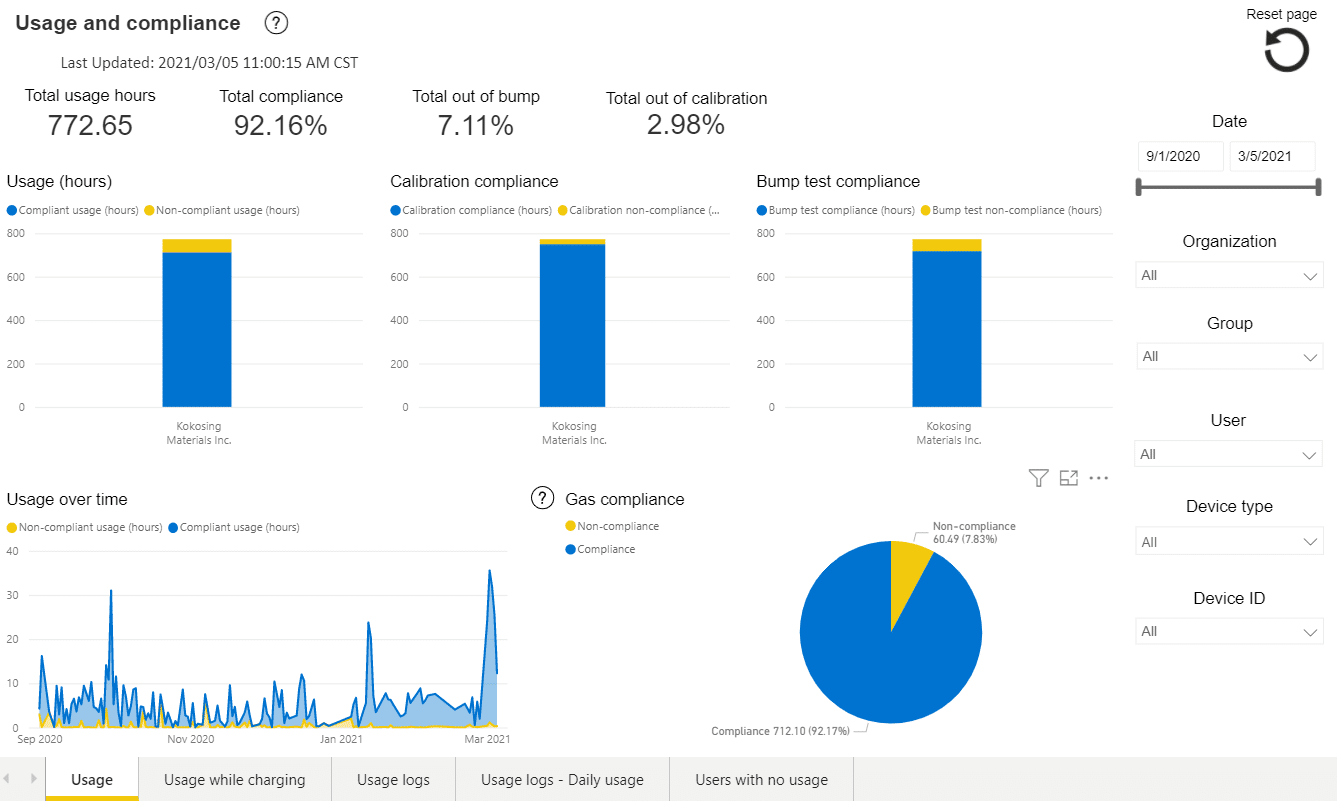

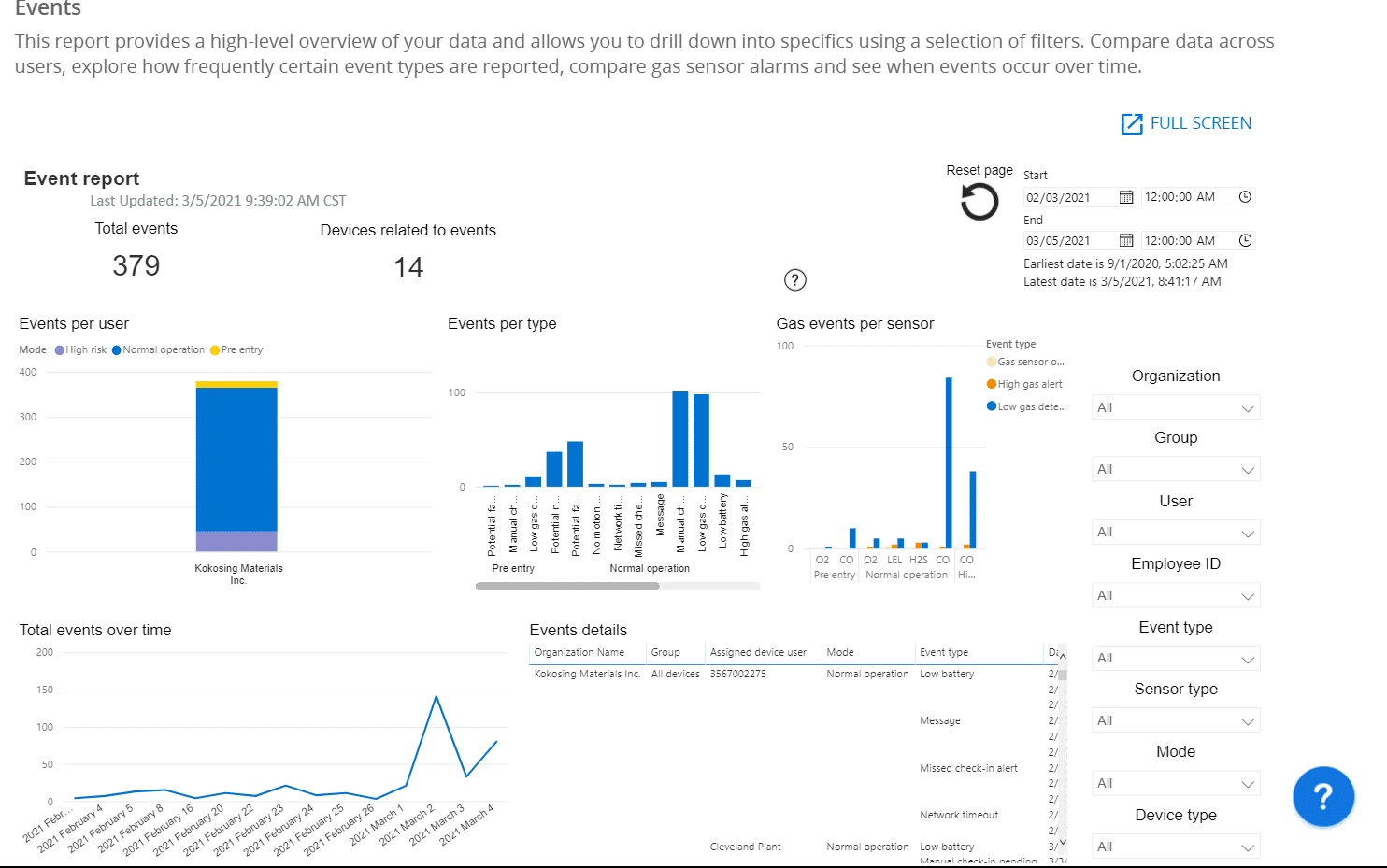

Now, Blackline’s monitors are Kokosing’s second person at the plant. It’s a wearable device about the size of a cell phone that can be clipped onto a belt or shirt. Kokosing opted for the model that also monitors hydrogen sulfide (H2S), carbon monoxide (CO), oxygen (O2) and lower explosive limit (LEL).

Whenever an employee is alone at the plant, all they need to do is grab a Blackline monitor to have instant access to help if they ever need it. “It’s very helpful for the last team member at the plant to have that help there,” Mull said, “and it gives family members some peace of mind.”

Kokosing also requires employees to use the devices whenever working in confined spaces or performing tasks requiring gas monitoring.

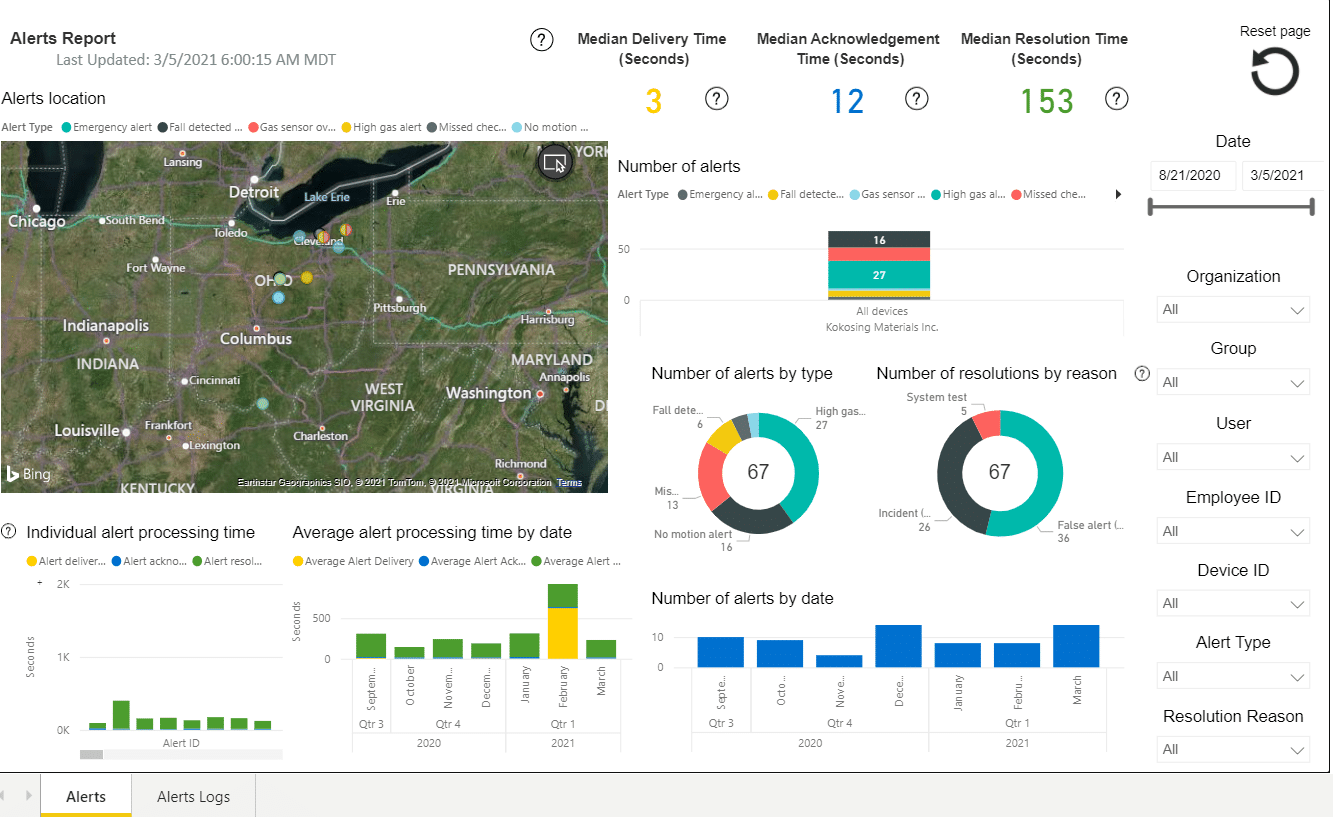

The lone worker solution is customizable, so Kokosing has set it up to suit their needs. They have a check-in alarm that goes off every hour, as well as alarms for the four previously mentioned gasses, a no motion alarm and a fall detection alarm.

If ever an employee doesn’t respond to an alarm, Blackline will talk to them through the monitor to ask if they are okay. If the person still doesn’t respond, Blackline will notify EMS who will be able to navigate directly to the site of the worker using the monitor’s GPS. “No matter where they are at the plant, EMS will know exactly where they are,” said Safety Manager Mike Farnsworth. Upper management at Kokosing is also notified.

Although Mull said the platform is very simple to navigate from a management standpoint, he did say it takes some time to perfect the settings for each alarm. For example, employees would set off the fall alarm when jumping out of a parked pickup truck. “We had to adjust the sensitivity, so they wouldn’t go off when we didn’t want them to,” Mull said. “That took some trial and error.”

Now, they’re experts and even have different settings profiles in the system so they can switch their units between different modes, like production mode and winter maintenance mode.

In addition to Blackline’s simplicity on the backend, it’s also simple for employees using the devices. “All they really need to do is turn it on,” Mull said. Training staff on how to use the devices was easy. “It wasn’t a tough rollout. The guys were actually happy about it.”

“When we followed up with everyone, we found that if they weren’t using it, it wasn’t because they didn’t want to but because they forgot about it,” Farnsworth said. Often, it’s a matter of the plant manager handing them out to whoever is left when he or she leaves. But, time and repetition also help. “Now it’s a habit.”

Kokosing first rolled out the lone worker solution to its terminals in 2018 and extended it to all of its facilities in 2019. “Whenever we use new technology, we want to test it out to see how it works,” Mull said. Its terminals were a perfect opportunity, because much of the work is performed by one person due to the hours they work. Terminals also presented additional H2S and CO hazards that the monitor could track.

Because the devices GPS-track all alarms, this solution has also helped Kokosing identify hazard zones around its facilities. “On the Blackline website, you can see every place where an alarm was tripped,” Farnsworth said.

For example, Kokosing changed its procedure at the loadout area of its Mansfield terminal after the original setup frequently tripped the H2S alarm. In another instance, they realized that the CO alarms were often going off on the back side of a newly built tank setup where the new air flows resulted in higher CO concentrations. “We resolved the issue by adjusting and tuning the heaters as well as looking at varying heights on the exhaust stacks,” Mull said. “We wouldn’t have known about it without the Blackline monitors,” Mull said.

Despite the success of its lone worker solution, Kokosing does not allow some tasks to be performed without having a second employee on site, including in confined spaces, electrical work and elevated work.

Thankfully, Kokosing hasn’t had any instances requiring EMS to be dispatched to its facility since implementing the lone worker monitors. In fact, Kokosing has worked more than one million hours (over four years) without a recordable injury.

“It’s sort of like an AED,” Mull said. “It’s great to have it, but you hope to never have to use it.”

“I think this really showed team members that Kokosing is looking out for them and cares for them,” Farnsworth said, “that they’re being proactive and they don’t need something to happen to want to keep people safe.”