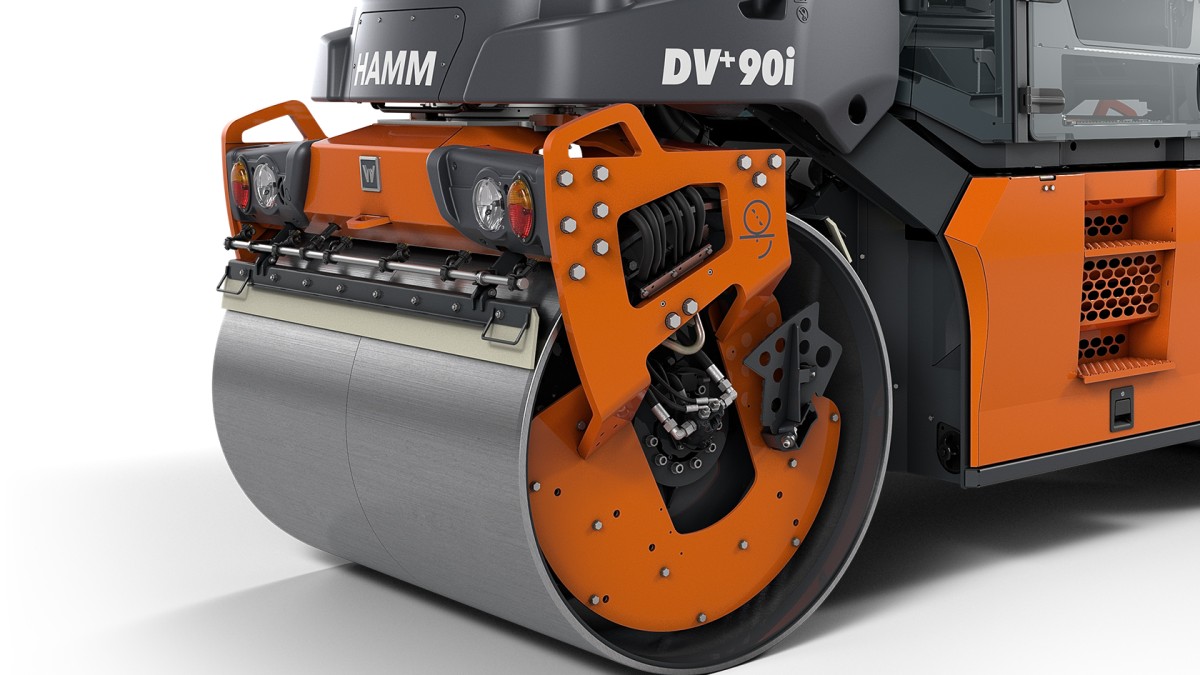

Hamm Offers Split-Drum Tech with DV+ 90i Roller

BY AsphaltPro Staff

The DV+ 90i roller represents the split drum technology available from Hamm, a Wirtgen Group company, Antioch, Tennessee. On the “OS” models, the rear drum is designed as an oscillation drum.

In the split oscillation drum from Hamm, one full oscillation unit works in each half. These two units are mechanically independent of each other. To ensure that the two drum halves always vibrate synchronously, despite their different rotation speeds around corners, Hamm has integrated an electrohydraulic control. This is designed to adapt the position of the unbalanced mass quickly and precisely to the position of the two drum halves.

In this way, shear stresses in the asphalt to be compacted are minimized. This, in turn, ultimately prevents material displacement and cracks.

In practice, the DV+ 90i VS-OS also scores highly among operators thanks to its low noise level. The reason for the reduced noise is, among other things, an optimized drive concept. Furthermore, Hamm uses a new type of toothed belt in all oscillation drums—in the split and non-split models.

The toothed belt therefore no longer needs to be changed after 2,000 operating hours, as was previously the case. This leads to an additional advantage because the oscillation drums are not only quieter than previous drums, they are also maintenance-free, according to the manufacturer.

The DV+ 90i VS-OS features a drum width of 66.1 inches and a weight of 22,182 pounds.

For more information, contact Matt Graves at matt.graves@wirtgen-group.com or visit www.wirtgen-group.com/america.