FORTA’s Surface-EXT Fiber & Ranger Feeder

BY AsphaltPro Staff

A properly-applied slurry seal or micro surfacing treatment will last an average of three to five years, depending on the state of the underlying surface. However, FORTA Corporation, Grove City, Pennsylvania, aims to extend the life of slurry seal and micro surfacing treatments by an additional three years with its Surface-EXT alkali- and acid-resistant glass fiber and its Ranger feeder. Here’s how they work.

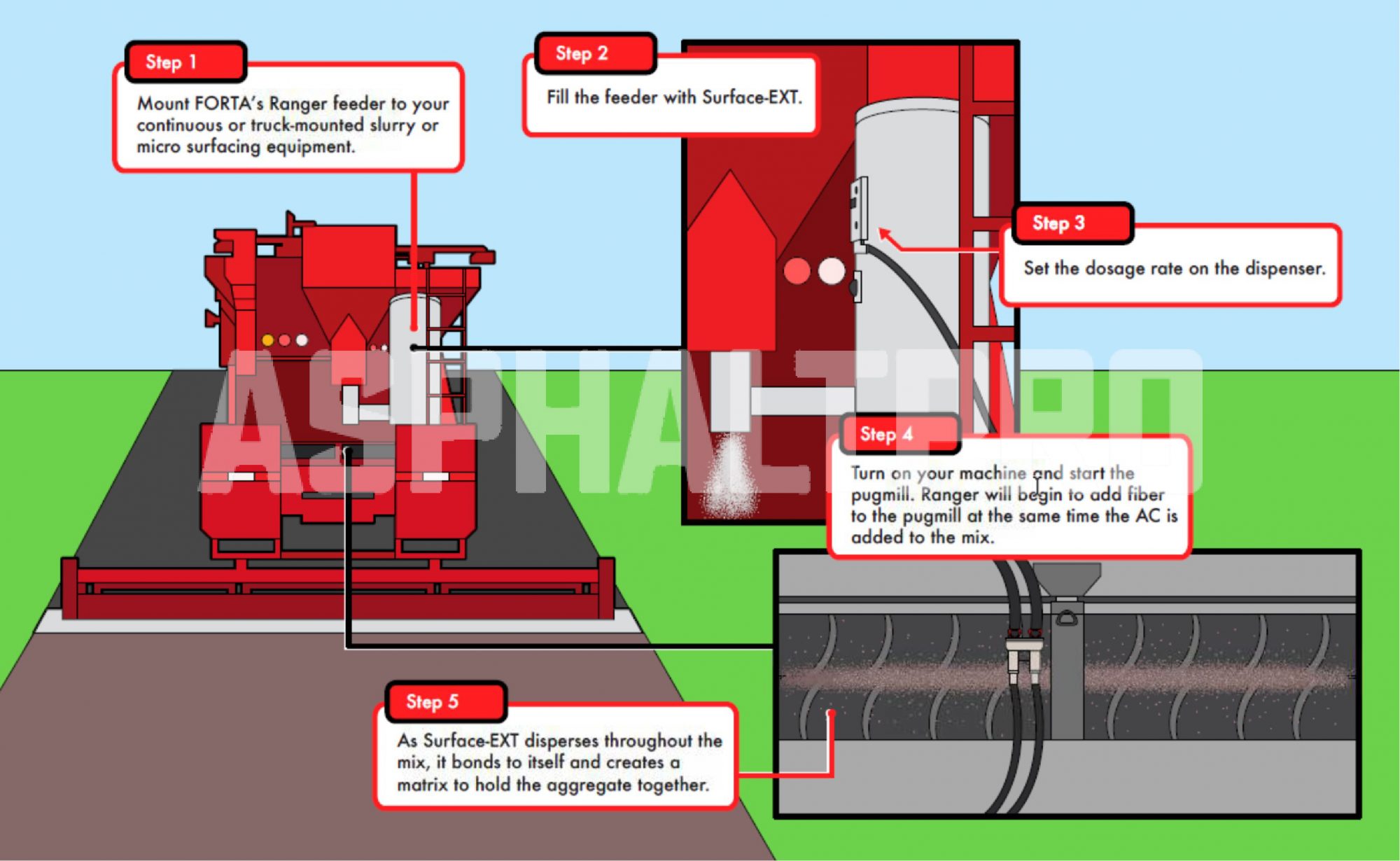

First, FORTA’s Ranger feeder must be mounted to any continuous or truck-mounted slurry or micro surfacing equipment. Once attached, the Ranger can remain on the machine at all times, whether or not fiber is being used on that project. When fiber is required on a job, the contractor will fill the feeder with Surface-EXT pre-chopped fiber.

Next, he will set the dosage rate on the dispenser, normally between 0.15 and 4 percent of the dry aggregate weight with most users adding around 0.2 percent. The feeder is controlled with the same controls as the rest of the pugmill components. The fiber is added on the front side of the pugmill, at the same time that the AC is added to the mix. Using Surface-EXT does not require any change to mix design and does not change the way paving crews operate.

To prevent the fiber from falling to the bottom or rising to the top of the mix, Surface-EXT has the same density and weight as the aggregate. As it distributes evenly throughout the mix, Surface-EXT creates a matrix that holds the aggregate together. This results in increased durability and flexural strength to reduce cracking and other distress.

For more information, contact Brian Engstrom at bengstrom@fortacorp.com or (724) 350-1330.