Cornejo & Sons Flags Work Zone Entrances, Exits

BY AsphaltPro Staff

Cornejo & Sons Inc., Wichita, Kansas, estimates that each of its 775 vehicles makes an average of six trips to and from job sites every work day. This amounts to more than 1 million vehicles entering and exiting work zones each year.

“Most construction sites have cones all over the place and it can be confusing for drivers delivering materials to know where to go,” said Safety Director Omar Franco. Cornejo & Sons determined that this exposed the company, its fleet and its workers to unnecessary risks.

A lack of consistent and well-marked work zone entrances and exits not only risked drivers damaging recently paved asphalt, hitting traffic control equipment or running over existing utilities, but also contributed to unauthorized and/or unsafe entrances and exits. For example, trucks could enter or exit a work zone by driving under power lines, across intersections, or on uneven or unstable ground. Even more seriously, there was the risk of employees in the work zone being struck by construction vehicles or by the traveling public as employees attempted to flag confused drivers into or out of the work zone.

NAPA’s next Safety Awards program opens Aug. 1, 2020, with a submission deadline of Oct. 15, 2020. Visit www.AsphaltPavement.org/Awards to apply.

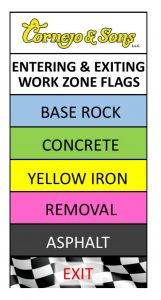

Cornejo & Sons decided to do something to reduce these risks. They began using color-coded flags to identify work zone entrances and exits–an idea for which the company was recognized as a finalist in the National Asphalt Pavement Association’s annual Safety Awards program.

“We want to take the guesswork out of it, and make it easy for drivers to follow our directions,” Franco said. “Now, everyone knows where the entrances and exits are.”

Cornejo Sons Inc work zone flags-asphalt: The flag denoting asphalt deliveries is white.

Safety Leadership, Safer Job Sites

Since 2014, Cornejo & Sons has organized a handful of safety leadership teams from across its operations to identify issues facing the company and brainstorm potential solutions each year.

“The first couple of weeks out in the field, everyone on those teams is paying a lot of attention to hazards and asking their fellow employees for ideas,” Franco said. “It boosts morale to know that the company is invested in keeping employees safe.”

It was one of the company’s very first safety leadership teams who identified the risks related to entering and exiting work zones. The team decided to create color-coded flags to denote construction vehicle entrances and exits for each work site. This enabled drivers to enter and exit work zones without verbal communication, thus reducing driver confusion, improving the safety of entry and exit points with less impact on the traveling public, and posing less risk to equipment and employees in the work zone. It also made it easier to specify entrances for different materials being delivered to the same job site.

Cornejo & Sons equipped all of its trucks, as well as hired-party trucks the company employs, with windshield stickers reminding drivers of the color-coding system.

“We may have miles’ worth of road we’re working on,” said Community Outreach Director Randy Roths. “The flags give drivers direction so they know where to pull into and out of a work zone, and crew members on the job know they need to stay out of those areas.” The flags also illustrate to subcontractors, inspectors and other third-party vehicles where equipment and vehicles can (and can’t) be parked on the job.

Flags In Action

All Cornejo & Sons job sites where trucks will be entering and exiting the work zone are required to set up specific color-coded flags for each type of material the site is expecting that day. In fact, crews are not allowed to order trucks unless the flags are set up.

The brightly colored flags are reflective so they are visible during both day and night jobs. They also spray painted text on each flag with its corresponding material, such as asphalt or removals. The total cost of each flag is less than $10, including the fabric flag and paint, the fiberglass pole, and bungee cords/clamps to attach the flag and pole to safety cones or barricades.

To encourage participation in the program, Cornejo & Sons conducted a safety meeting with each crew before implementation and prepared a toolbox talk printout and a best practices checklist in English and Spanish.

The foreman on any given job places two colored flags at the entrance and two checkered flags at the exit, attaching them with bungee cords to safety cones, concrete barriers, or whatever else may be available at those areas.

The best practice checklist reminds foremen to make sure the cones are spaced wide enough to allow trucks to enter, and that the entrances and exits have a safe slope, are stable, do not have power lines overhead and offer safe re-entry into traffic.

Visit this article on theasphaltpro.com to download Cornejo’s checklist and Toolbox Tip sheets in English or Spanish.

Because paving jobs are always moving, the foreman on those jobs places just one entrance flag on the paver itself.

In addition to making it easy for crews to comply, Cornejo & Sons also wanted the system to be easy for truck drivers. The company equipped all of its trucks, as well as hired-party trucks the company employs, with windshield stickers reminding drivers of the color-coding system. The flag color is also included on the driver’s delivery ticket. (See the image on this page).

Cornejo Sons Inc work zone flags-exit (small): The flag denoting all exits from the work zones are checkered.

Enter: Results; Exit: Risk

According to Cornejo & Sons, the risks associated with unclear entrances and exits has been reduced by more than 70 percent since the company implemented its color-coded flag system.

Within the first year of the program, some of the contractors Cornejo & Sons works with noticed the flags and thought they were a good idea. “They would request that we bring the flags out to jobs we’d do together,” Franco said. “It’s neat to be able to share that with them.”

Since they began the flag program, Cornejo & Sons has continued to make improvements. For example, the flag for asphalt used to be black and was difficult to see on night projects. Now, the asphalt flags are white.

“At first, the foremen weren’t thrilled to have one more thing to set up,” Roths said, “but they’ve grown to appreciate not having to chase down trucks who’ve missed turns.”

Not only do the flags save crews time and reduce driver confusion, but they also make the work zone safer for everyone.

Cornejo & Sons employs more than 575 workers across its various subsidiaries. The company, which serves the construction industry in Kansas and throughout the Midwest, offers aggregate production and delivery, asphalt production and paving, pavement maintenance, heavy highway construction, stone quarry and sand mines, and site development and construction, among other operations.

“Safety is number one around here,” said Safety Director Omar Franco. “It’s the first thing we talk about with new hires, we are committed to Toolbox Talks, we do safety lunches and safety training throughout the year.” At the start of every construction season, Cornejo & Sons has a safety kickoff pancake breakfast for 400+ employees so everyone starts the year off with a safety mindset.

Since 2014, Cornejo & Sons organizes a handful of safety leadership teams from across its operations each year to identify issues facing the company and brainstorm potential solutions. The safety leadership teams are voluntary, “though we voluntold people to do it the first couple years,” Franco joked. The teams meet once every two weeks to determine the problem they want to solve and brainstorm and implement solutions, which are ultimately presented to upper management at Cornejo & Sons and at its parent company, Summit Materials, Franco said.