Cat Safety VR Offers Dunn Construction a Safe Place to Fail

BY AsphaltPro Staff

The Dunn Companies, Birmingham, Alabama, encompass 10 operating companies serving the real estate development, civil construction, building construction and maintenance, ready-mix concrete and asphalt industries.

To continue growing over the course of the company’s 141-year history, workforce development has been integral to the company’s success. Now, more than ever.

“At the end of the recession, there were seven people for every open job in our industry,” Chris Stricklin said. “Now, there’s less than one person available per open job.”

Stricklin was hired to lead Dunn University, established February 2019, to recruit, train, develop and retain the company’s 1,800 employees.

Real Problems, Virtual Solutions with Cat Safety VR

To get all crew members through the training, Dunn has a clerical employee head to the shop 45 minutes early a couple mornings each week alongside a couple members of the crew to run them through the training and then drive them out to the jobsite.

Around the time of the launch of Dunn University, Cody Jackson was sent a picture of Cat® Safety VR, a virtual reality safety training program by Caterpillar Inc., Peoria, Illinois, that was on display at World of Asphalt. Jackson is the safety manager at Dunn Construction, one of Dunn Companies’ four asphalt companies.

Virtual reality (VR) immerses the user in a simulated environment with which they can interact. Stricklin was immediately interested in what the VR training could offer Dunn University. By mid-April, Dunn had acquired the first Cat® Safety VR system.

“I was a fighter pilot in the Air Force, so I understand the importance of having a safe place to fail,” Stricklin said. Even though the training tool had yet to hit the market, he knew he wanted a headset for Dunn University. “Everyone has a first day on the job. Nothing is more important than understanding what they’re walking into, how to be safe themselves and how to help others be safe.”

Prior to Dunn University, each company under the Dunn umbrella was training in its own way. For Jackson and the employees of Dunn Construction, that meant training in the conference room and, later, taking new employees to the job site and walking them through various situations.

“In the past, classroom presentations were the only way we could get that information out there to new employees before they get on the job,” Jackson said. “In this industry, it’s so hard to speak into new employees what they’ll be faced with on the job site: cars zipping by at fast speeds, maybe hitting cones. With VR training, we can get that base of knowledge before they get out on the job site. It gets something turning in their brains where they realize this is not just a walk in the park. They can’t get complacent; they have to listen to what the foreman tells them to do.”

Cat Safety VR: New Tech, Unexpected Use Cases

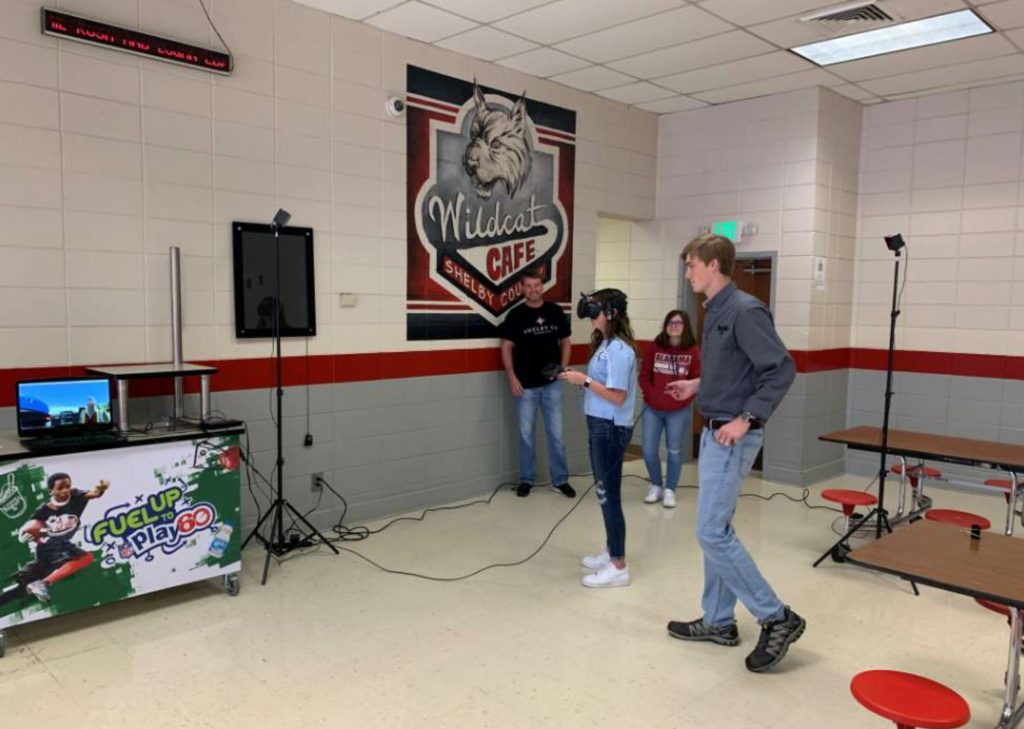

Oct. 17, 2019, Stricklin and Jackson took the Cat® Safety VR system to Shelby County High School in Columbiana, Alabama, where they had two Driver’s Education students and the instructor go through the simulation to encourage safe driving behavior through work zones.

Although Dunn originally wanted the VR training for new employees, what they found was that it also helped mitigate complacency among more seasoned employees. “People who’ve been doing this for a while sometimes get into bad habits,” Stricklin said. “The VR system makes them rethink safety.”

They also have their executives go through the VR training. Although Dunn executives have all been out on job sites, the VR training is a useful reminder of what the crews are dealing with on a daily basis. “We’ve always had a safety mindset in all of Dunn’s companies, but this was a great renewal of that mindset,” Stricklin said.

Dunn doesn’t require employees to make it through the entire 30-minute training experience flawlessly—and for good reason.

“We feel like that would lead to people telling their friends what to watch out for,” Jackson said. The way they’ve been doing it, they say, has actually led to a friendly competition. “We ask people not to tell anyone else what to watch out for because that would hurt someone else’s training and we want everyone to experience it for themselves.”

Employees also were not told that it was possible to simulate injury in the VR simulation. When they do make a mistake that would result in injury in the real world and the screen goes red, Jackson said, “it really hits home with them, that if they don’t do their job safely, they could actually die.”

In fact, he added, the VR experience has made safety the topic of conversation around the water cooler. “Everybody would be talking about how they did on the VR headset,” Stricklin said. “It’s great to see people competing to see who can be the safest. Safety was being talked about in every venue of our company.”

Dunn also uses the Cat® VR safety training as a recruitment tool. In fact, Stricklin said, that was the very first place they debuted it. “[Caterpillar Safety Services’ business development manager Justin Ganschow] rushed it over to my office for a recruitment event,” he said.

The Dunn Companies encompass 10 operating companies serving the real estate development, civil construction, building construction and maintenance, ready-mix concrete and asphalt industries. To continue growing over the course of the company’s 141-year history, workforce development has been integral to the company’s success.

Normally, Dunn brings in a paver to try to entice young people to stop at their booth and discuss career opportunities. Now, they bring the VR headsets and the drones they use to generate three dimensional volumetric models of Dunn’s job sites, plants and stockpiles, to determine road grades, assist with quality control, capture aerial photography and manage stockpile inventory.

“They come over to see what that’s about and they learn that construction is more than using a shovel and a hammer,” Stricklin said. “We’re flying drones and training on VR headsets.”

Dunn also took the VR headset to a regional safety summit at the University of Alabama for contractors of all kinds from across the state. “It was an eye-opener for people working in other areas of the industry,” Stricklin said. “People were talking about how they never realized how hard it was out there building roads. Every area of construction is dangerous, but vehicles coming past you at 80 mph is a different kind of danger.”

In fact, Stricklin and Jackson think that this VR training could be useful to encourage safer driving through work zones. Oct. 17, 2019, they took the Cat® Safety VR system to Shelby County High School in Columbiana, Alabama, where they had two Driver’s Education students and the instructor go through the simulation.

“The first student screamed and actually ducked to the ground,” Stricklin said. The response from the second student was similar. “They both said that they would never drive through a construction zone the same again and had no idea what it was like to work beside moving cars like our teams do each and every day.”

This is a sentiment Ganschow has also experienced firsthand.

“One of the first reactions I had to the VR training was on a podcast with the Association of Equipment Manufacturers,” Ganschow said. “The first reaction of the interviewer [Dusty Weis] was, ‘I’m changing my behavior in construction zones.’ People need to know that even a momentary lapse in attention can cause a disaster and alter many peoples’ lives.”

Facilitating Cat Safety VR

The Dunn Companies established Dunn University February 2019 and works to ensure each of its 1,800 employees have completed the Cat® Safety VR training program.

Although new tech can sometimes seem complicated, Stricklin said unpacking, setting up and running the VR headset is a non-issue. “It’s so simple, we made a picture-by-picture instruction page and now anyone can set it up in three minutes,” he said.

“Our biggest challenge is that we only have one,” Stricklin said, adding that they intend to purchase more units in the future.

Originally, Stricklin and Jackson discussed having employees go through the VR training during the slow season, but Stricklin didn’t want to wait. Jackson came up with the idea to have a clerical employee head to the shop 45 minutes early a couple mornings each week alongside a couple members of the crew to run them through the training and then drive them out to the jobsite. On rainy days, they’ll run entire crews through the VR training.

As soon as all of the employees at Dunn Construction complete the VR training, Stricklin will take it to Dunn’s other three asphalt companies and eventually to its aggregate and concrete companies. Eventually, Dunn would like to have every one of its 1,800 employees experience the VR training.

“Even though the modules focus on asphalt paving, the training has tangible safety benefits in other areas as well,” Stricklin said. They also look forward to Caterpillar adding new training modules to the program in the future. “As soon as we got the VR training, we immediately thought about how helpful it would be to have a training simulation for our quarries.”

Ganschow said Caterpillar intends to produce additional modules as they identify partners within the industry to help develop modules on other topics.

“We want to serve all industries where Cat is present, whether that’s mining or quarry, aggregate or construction,” Ganschow said. Their next module, he added, will most likely cover general safety on or around their equipment, specifically focusing on higher hazard maintenance and servicing tasks, as well as weather hazards, stability issues, and working safely within a dynamic environment where equipment is moving around. “There’s really no end to what we can simulate.”

For now, Dunn will continue to train its employees with the asphalt paving module currently available.

“When an Air Force guy comes into your organization and says he wants to buy a VR headset to replicate what you’ve been doing your whole life, it’s a hard sell,” Stricklin said. “Now, everyone’s saying, ‘What did we do without this for 141 years?’”

“Every aspect of the VR training is something we experience every single day,” Jackson said. “It’s an atmosphere where people can safely fail.”