Find New Asphalt Production Parts for More Tons

BY AsphaltPro Staff

We’re deep into paving season now. If you find yourself in need of components or updates at the asphalt plant, the original equipment manufacturers (OEMs) listed on the next few pages have parts, pieces, controls, software and whole plants to enhance your bottom line.

Ammann

The ABP high recycling technology (HRT) plant from Ammann Group

Ammann Group, Langenthal, Switzerland, celebrates its 150th anniversary in 2019. The business was started in Switzerland and now has operations around the world. It entered the North American market a few years ago with the introduction of key asphalt mixing plants, including those that incorporate high percentages of RAP. Check out the article, RAP Management LLC Does it First, on www.TheAsphaltPro.com to learn about one in operation right now.

The Ammann ABP high recycling technology (HRT) asphalt mixing plant is designed for manufacturers who need to incorporate large proportions of RAP without sacrificing production capacity and quality. The ABP HRT plant features both warm and cold recycling systems that can be used simultaneously. The striking visual difference between the ABP HRT and traditional plants is the vertical stacking of the RAP-bearing components; the configuration is designed to reduce wear and sticking, and shortens the travel distance of hot RAP material. The plant has a production capacity of up to 440 U.S. short tons per hour and can use foamed bitumen, pigments and other additives.

Ammann also offers its UniBatch plant, ACM Prime plant and the RSS 120-M shredder.

For more information, visit www.ammann.com.

Astec

The satellite silo system from Astec allows operators to establish a retail location away from the parent plant.

Astec Inc., Chattanooga, announced just prior to WOA its satellite storage systems.

“Stand-alone mix storage systems allow operators to establish a retail location within a transportation radius of the parent plant. These storage systems enable users to expand into a location that does not yet justify a plant, while the smaller footprint of the silo system can accommodate installation at small sites that can’t support a full plant. Satellite silo system components include a truck unloading hopper (to receive mix from the trucks to fill the silos), inclined drag conveyor, long-term storage silos with anti-segregation batchers, traverse conveyors to deliver mix into the selected silo and controls.”

For more information, visit www.astecinc.com/SatelliteSilo.

ClearSpan

The new Armor Shield cover material from ClearSpan is available now.

ClearSpan Fabric Structures recently released the exclusive Armor Shield Cover, which is a 29-ounce architectural vinyl building cover that is designed for ultimate durability. ClearSpan stands by the durability of this new cover with a 30-year warranty.

The protective membrane consists of seven layers, including a sturdy base fabric, multiple layers of protective coating and dual-sided PVDF top coat that increases durability and repels dirt, all to create a long-lasting tensile fabric of the highest quality. The cover is both mildew resistant and flame retardant, according to the manufacturer.

This new material has gone through rigorous testing, and withstood over 900 pounds in a grab strength test, surpassing the maximum strength capacity of the testing machine. The high-tensile strength allows users to customize structures with architectural design elements without compromising the integrity of the building.

The new Armor Shield Cover is available to outfit ClearSpan’s extensive line of building styles in white, gray, tan and green. A 12-ounce poly cover accompanied by a 20-year warranty is also available for all ClearSpan buildings upon request.

For more information, request a quote.

CWMF

The Honey Badger Rap Crusher is designed to crush RAP in any asphalt location.

CWMF Corp, Minnesota, announces the official release of its new product line, the Honey Badger Rap Crusher. The Honey Badger Rap Crusher is equipped with replaceable AR steel wear liners and a ½-inch steel pulverizing hopper. The Honey Badger rotor assembly includes 3-inch premium grade cast carbide hammers, a precision-machined shaft, ¾-inch rotor disks and grease lubricated pillow block bearings. Included is a two-way valve hydraulic power pack that allows for easy interior access but, most importantly, performs a controlled close of the hopper top so that safety is never compromised.

CWMF offers two models, the HB-30 and HB-40. The HB-30 has a feed opening of 23 x 31 inches, a 50-horsepower TEFC motor, and rated at 20-50 tons per hour. The HB-40 has a feed opening of 23 x 35 inches, a 60-hp TEFC motor, and rated at 30-60 TPH. To get the RAP to the proper size, CWMF offers ½-inch, ¾-inch, 1-inch, 1-1/4-inch and 1-1/2-inch AR steel grates in both models.

Portable and stationary setups are available. The Honey Badger portable chassis is also equipped with a CWMF Tremor shaker and conveyor to get RAP processed on-site at any asphalt location.

For more information, call (877) 457-3938

Delair

Delair, headquartered in Toulouse, France, introduced a new model of its popular long-range UAV, the Delair DT26, which offers an easy-to-integrate architecture for adding user-specified sensors and other payloads to the platform. The Delair DT26 Open Payload model features a removable container which can hold up to 3 Kg of extra payload and be connected to a power supply of up to 140W. It allows drone users to add specialized sensors for specific imagery needs, such as ultra-high resolution, multispectral and hyperspectral, thermal and oblique imaging capabilities. An optional cargo rack can be used to transport any type of items up to 3 Kg over the long distance range the UAV supports. The Delair DT26 Open Payload model is supported by a technical diagnosis service that helps customers evaluate the compatibility of their specific payloads with the UAV’s architecture.

The Delair DT26 features a long endurance flying range of up to 135 minutes, enabling it to operate in BVLOS (beyond visual line of sight). The integrated communication system supports both command and control as well as video datalink connectivity via radio or 3G cellular, and a maximum range of 30 km. It comes with flexible mission planning and control software.

The Delair DT26 Open Payload model offers typical deployment time of under 8 minutes. It can be launched in small spaces via its catapult take-off mechanism and features highly accurate belly landing capabilities, according to the manufacturer. Fully configured it weighs 17 Kg and features quick assembly components.

For more information visit to www.delair.aero.

Epiroc

Epiroc, headquartered in Commerce City, Colorado, showcased its hydraulic attachments in the National Demolition Association (NDA) live DEMOlition event at the Demolition Rockies convention, March 23, 2019, in Aurora, Colorado. Back by popular demand, the second annual hands-on demonstration event offered attendees the opportunity to test and operate a variety of demolition equipment.

One specific Epiroc hydraulic attachment featured in the demo was the SB 202 hydraulic breaker. The SB hydraulic breakers are designed for demolishing light concrete structures and asphalt pavements. They come standard with an integrated water port for dust suppression to enhance operator safety and to assist in compliance with Occupational Safety and Health Administration (OSHA) final silica rule regulations. SB breakers require minimal routine maintenance, which makes them a cost-effective option with minimal downtime. The SB 202 breaker is designed for the 5,500- to 13,000-pound carrier weight class.

Epiroc hydraulic attachments are supported by the North American Competence Center in Independence, Ohio. The facility combines a customer center, repair shop and configuration center, and parts and supplies warehouse with a team focused solely on hydraulic attachments to support the U.S. and Canadian attachments market.

For more information, call (844) 437-4762.

Kenco

The TCI serrated cutting edge from Kenco is designed to penetrate old and hardened RAP piles more easily than a standard flat blade.

Kenco Engineering Inc., Roseville, California, offers its Kenco Tungsten Carbide Impregnated (TCI) serrated cutting edge. The serrated edge design allows buckets to penetrate hardened reclaimed asphalt pavement (RAP) piles without using teeth.

“Designed to give some of the benefits of teeth along with the benefits of a straight cutting edge, the Kenco serrated Tungsten Carbide Impregnated (TCI) cutting edge will penetrate old and hardened RAP piles more easily than a standard flat blade, but won’t leave trenches in the yard floor the way teeth will. Though trading some overall wear life for better penetration, the Kenco serrated design still gets the benefit of our unique TCI process. Get the best of both worlds with the Kenco serrated TCI cutting edge, good penetration with good wear life.”

For more information, contact Paul McDowell at (916) 782-1796.

MINDS

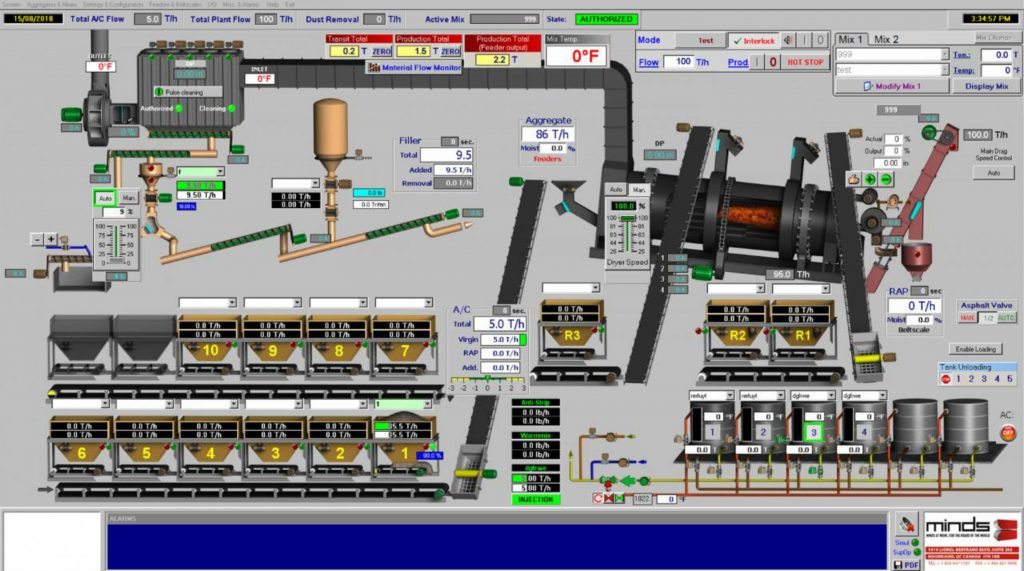

MINDS’ DrumTronic asphalt plant automation and control software screen

A highway construction firm in the United States that operates many asphalt plants was using multiple asphalt plant automation systems prior to 2019. The various plant control software was not compatible with each other, making it difficult for the firm to understand at a company-wide level how its plants were performing in relation to each other, ensure production standardization and accuracy across its operations, and train plant staff.

In 2009, the company made the switch from its multiple plant control systems to the DrumTronic software for asphalt plant automation and control from MINDS Inc., Boisbriand, Quebec. MINDS’ customizable asphalt plant software was designed after consultation with plant operators to allow plant managers to get a quick and clear understanding of their operations, and handles everything from simple blending to total plant control.

The construction firm saw immediate improvements from switching to the MINDS software beyond the simplicity of having one plant control solution instead of several. The simplicity of use is thanks to the way DrumTronic was designed to communicate all the metrics that operators need to understand, to prevent confusion and misinterpretation of data. MINDS prioritized symbolizing information clearly, such as how delays and timing can be shown over a graphic representation of material flow and plant.

By standardizing on a system, the company was also able to reduce the amount of time it was spending on operator training and orientation. With DrumTronic, the company had the ability to move personnel from plant to plant without re-training. The MINDS system is highly customizable and has a consistent interface on drums, batches, hybrids plants, or even bitumen terminals and emulsion plants, “When they opened the door in the control house, it was an identical screen that they had from their old plant,” said the plant maintenance manager. With more than 30 personnel who would need to know how to operate the plant software, this was a huge time savings.

For more information, contact (866) 938-1124.

PHCo

The hot oil heater from Process Heating Company

Process Heating Company, Seattle, offers its Lo-Density® Hot Oil Circulating Heater systems to provide automatically controlled, even-temperature heat-transfer fluid. The systems offer unique benefits for asphalt plants, including lower operating costs, improved product quality, reduced maintenance, longer heater life and enhanced sustainability, according to the manufacturer. With the PHCo indirect heating systems, heat from electric energy is transferred to the oil, which then carries it to the area or process where it is needed. Using PHCo’s unique Lo-Density patented Coil-Lock-design heating elements, which reside within a drywell, the units dissipate controlled heat as low as eight watts per square inch on the heater’s sheath. This is designed to eliminate coking or carbonization of the transfer oil. Because the drywell-style elements are accessible from outside of the system, they also may be serviced without draining the heater.

Each Hot Oil Circulating Heater is a complete system that includes a properly sized, vented expansion tank with a sight glass and a low-level shut-off switch. Like all fluids, heat transfer oil expands when heated. The expansion varies with the temperature to which it is heated. For example, 100 gallons of oil at 50° F will expand to 114 gallons when heated to 450° F. The expansion tank permits expansion of oil as it is heated, without exposing hot oil to air. It functions as an oil seal to accommodate the increased volume of expanded oil in a quantity of colder oil, which comes into contact with a limited amount of air. The low temperature of the oil seal will contribute to the long service life of the oil. A secondary function of the expansion tank is to provide a means for the escape or intake of air as the oil level in the tank rises and falls.

The system also includes an exchanger built to ASME standards, covered with high density insulation and an aluminum jacket. There is a motor-driven, special high-temperature centrifugal pump for circulating heat transfer oil, and a UL-listed industrial control panel in a weatherproof enclosure, with standards that include a programmable time clock for early morning startup, main indicating controls, and over-temperature controls.

Also contained in the package are additional features on these heaters, including a strainer for easy cleaning, shut-off valves for the system and the fill lines, and strategically located air purge valves to assist in filling the system. PHCo Hot Oil Circulating Heater systems are completely pre-wired, pre-plumbed, and ready for installation.

With fluctuating energy prices, efficiency becomes critical to the cost of doing business. One PHCo customer, F&R Asphalt of Easley, South Carolina, replaced its diesel-fired hot oil with a PHCo electric hot oil heater in 2009. The diesel system had burned 800 gallons of fuel per week, and F&R Asphalt was paying $4.00 per gallon—resulting in weekly fuel costs of $3,200 (an annual cost of $166,400). After switching to the PHCo electric hot oil heater, the customer was able to reduce heating costs to $210.10 daily, for an annual cost of $76,686—and an annual savings of $89,714. Given today’s energy costs, with diesel fuel at approximately $3.00 per gallon and industrial electricity costs at about the same as 10 years ago, the data is still relevant.

For more information, call (866) 682-1582 or visit www.processheating.com.

Topcon

Topcon Positioning Group, Livermore, California, announces the next generation flight planning system for its rotary-wing aerial UAV offering—Intel® Mission Control Software. The new software is designed to facilitate automated flight planning, managing missions, and data handling for the Intel® Falcon™8+ Drone–Topcon® Edition and its available payload options. The software is designed to increase accuracy with advanced mapping features that allow operators to set project parameters and prepare missions using presets for 2D areas like polygon, corridor and city grid, as well as 3D structures like towers, buildings and facades.

“Operators can take advantage of 2D and 3D map views with the ability to import more precise project details and parameters, including restricted airspace, and support to adapt flight planning over difficult terrain,”

Charles Rihner, vice president of planning for Topcon Emerging Business, said.

Additionally, the software includes automatic pre-flight safety and system checks while in mission planning. The flight planning software is also designed to improve data handling and export to support easier data processing.

For more information, visit Topcon at topconpositioning.com.