WMA Use Increases Gently, NAPA Reports

BY Kent Hansen, Audrey Copeland and T. Carter Ross

In 2007, a group of asphalt pavement experts from the United States travelled to Belgium, France, Germany and Norway to learn about various warm-mix asphalt (WMA) technologies as part of a Federal Highway Administration (FHWA) technology scanning tour. Eight years later, what was once an interesting idea is now a standard practice across most of the nation. In 2015, about a third of total asphalt mix produced in the United States was produced as WMA with a temperature reduction of at least 10°F compared to hot-mix asphalt mixes.

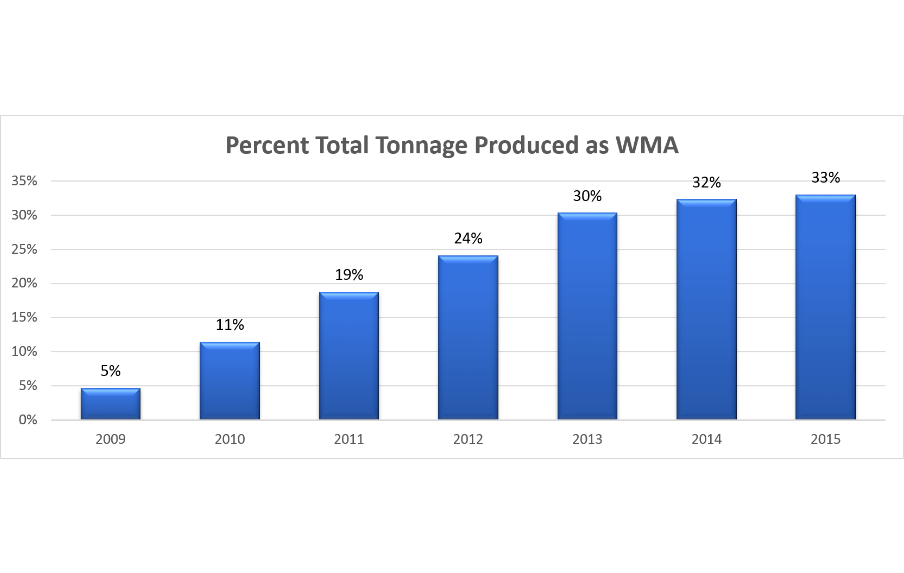

Figure 1. Percent of Total Tonnage Produced as WMA from 2009 to 2015

For each construction season since 2009, the National Asphalt Pavement Association (NAPA), working cooperatively with FHWA, has surveyed the industry on the use of WMA, as well as the use of recycled materials.

The 2015 construction season survey results were released in March 2017, and NAPA is currently surveying the industry about use of these technologies and materials during 2016.

The first survey found that barely 43 percent of U.S. mix producers used WMA technologies in 2009 and only about 16.8 million tons of WMA (4.7 percent of total tonnage for the year) was produced. Since that time, growth in warm-mix production has increased dramatically, although the adoption curve has begun to plateau (See Figure 1).

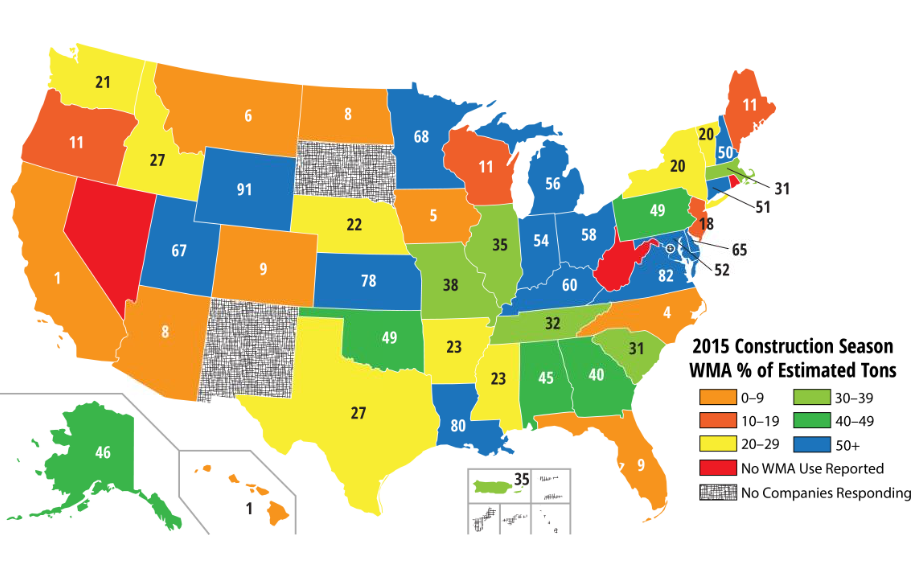

Figure 2. State-by-State Percent of Total Tonnage Produced as WMA in 2015

During the 2015 construction season, some 119.8 million tons of WMA was produced, making up 32.8 percent of total production during the year. Seventy-eight percent of producers reported using WMA to reduce production temperatures, and about 60 percent of respondents noted they also use WMA technologies at hot-mix asphalt temperatures to gain construction benefits. The 2015 numbers are a dramatic 613 percent increase in WMA tonnage and a 600 percent increase in the use of WMA when considered as a percent of total tons since 2009. It is also a greater than 5 percent increase in tonnage over the 2014 construction season and a 1.6 percent increase when considered as a percent of total tons.

State departments of transportation remain the biggest customers for WMA. Nearly 37.4 percent of tons produced for DOTs was produced as WMA. For other public agencies, such as cities and counties, 34 percent of the tonnage was WMA. For commercial and residential customers, the percentage was slightly higher at 34.3 percent.

IS-138 is now available. To download a full copy of the survey, visit www.AsphaltPavement.org/recycling.

Figure 2 shows WMA use as a percent of total asphalt mixture production in each state. WMA makes up over half of the total asphalt mix production in 14 states, and four of them—Kansas, Louisiana, Virginia and Wyoming—reported WMA as 75 percent or more of total production in 2015. Nevada, West Virginia and Rhode Island did not report the production of WMA in 2015. As states continue to update specifications and approve WMA technologies, room for growth in WMA production remains.

Of the available WMA technologies, plant foaming remains the most common, being used for 72 percent of the WMA produced in 2015. The use of chemical additive technologies reached an all-time high in 2015, accounting for a little more than 25 percent of the WMA produced.

Additive foaming and organic additives make up the remainder of the market. The percent of WMA produced with additive technologies has grown significantly since 2011 when they made up less than 5 percent of the WMA technologies used.

In total, 214 companies representing 1,119 plants participated in the survey. Responses came from 48 U.S. states plus Puerto Rico.

- Kent Hansen

- Audrey Copeland

- Carter Ross

Kent Hansen, P.E., is director of engineering for NAPA and manages the annual survey.

Audrey Copeland, Ph.D., P.E., is vice president for engineering, research and technology at NAPA.

T. Carter Ross handles communications for the association.