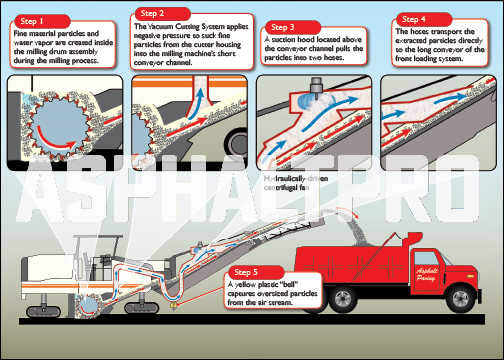

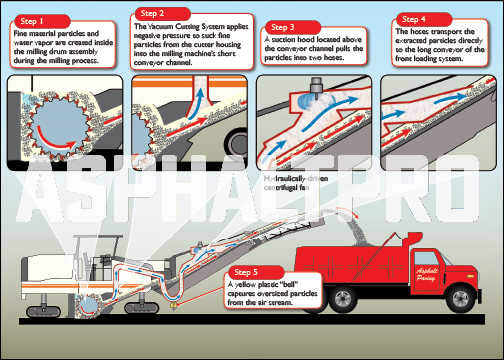

Wirtgen’s Vacuum Cutting System

BY AsphaltPro Staff

Wirtgen GmbH introduced its Vacuum Cutting System (VCS) for use in front-loading road milling machines to suppress airborne material particles, which are produced by the milling process. All Wirtgen’s larger cold mills can be fitted with the CVS to extract fine material particles at the cutter drum. By creating a negative pressure in the drum housing, the mix of air and water vapor Is evacuated and then fed back into the flow of the milled material transported on the conveyor via a hose system. Here’s how it works.

First, fine material particles and water vapor are created inside the milling drum assembly during the milling process. VCS begins by applying negative pressure to suck these fine particles into the milling machine’s short conveyor channel. Additional sealing of the milling drum assembly supports this process.

A suction hood located above the conveyor channel sucks the particles into two hoses, which transport the extracted material particles directly to the long conveyor of the loading system. Again, the process is supported by sealings in the short conveyor channel and at the suction hood.

A hydraulically driven centrifugal fan installed on the conveyor makes sure the extracted material is fed into the long conveyor channel. Negative pressure is created in the milling drum assembly at the same time. Additional injection of water at this point binds most of the particles. The water-bound particles are finally returned into the stream of material and are, for the most part, fed into the truck together with the milled material during the loading process.

Better air quality and visibility in the working environment of the milling machine operator and ground crew members improves crew comfort and productivity, while reducing wear and tear on the machine.

For more information, contact Wirtgen America at (615) 501-0600 or visit www.wirtgenamerica.com.