What’s New in Plant Production

BY Sandy Lender

AsphaltPro sets the standard for equipment and service information by focusing on what’s new in the industry. There are companies in the asphalt industry with R&D departments that have crafted remarkable components for aggregate and asphalt production that stand the test of time. Over the years, those components require mere tweaking here and there to bring them up to date with some new code or concept the EPA dreams up. As those modifications are introduced, AsphaltPro is honored to share the information with readers, keeping everyone abreast of changes in our industry.

Then there are companies with R&D departments that revamp complete systems, software, iron and parts to make completely new products to address different needs in the aggregate and asphalt production realm. It takes guts to put in the time, money and manpower to fabricate a new WMA injection system, a new material delivery system atop the silos, a new burner, and the list goes on. When a manufacturer launches a new product, again AsphaltPro is proud to share that news with readers, keeping everyone up to date with the advancements in our industry.

For the 2016 calendar year, the product galleries will again focus on one of the two main branches of our industry: paving and pavement preservation/pavement maintenance in one edition, and production of aggregates, asphalts and mixes in the next. This month, I asked OEMs and others in the industry to provide information related to mix production for equipment and services they launched in the latter half of 2015. You’ve seen the old stuff. In alphabetical order, let’s take a look at what’s new in the asphalt production market place to enhance your bottom line.

Heatec now offers the remote monitoring system RECON™. Visit www.heatec.com.

From Heatec

As of December 2015, Heatec, Chattanooga, offers the RECON™ monitor system to keep plant operators informed about the status of asphalt storage tanks and hot oil heaters. It’s a web-based system that uses your smart phone, tablet or PC to show real-time status of the hot oil heater, of asphalt stored in tanks, of trend data and other options. “Plant operators were asking about the possibilities of monitoring their asphalt heating and storage systems using a smartphone,” a spokesperson for Heatec explained. “Managers and operators can easily monitor the operating status of their asphalt system remotely. They also can get historical information on usage, etc.”

• Use this at the tank farm.

• For more information, contact Heatec Parts Department at (800) 231-5200 or (423) 821-5200.

Kenco offers the new Longhorn cleaning tip. Visit www.kencoengineering.com.

From Kenco

As of November 2015, Kenco Engineering, Inc., Roseville, California, has released the new “Longhorn” cleaner tip for the Double Barrel® style asphalt plant. “Many customers have reported increased wear on their mixer tips due to asphalt buildup on the floor of the plant mixer section. This buildup, while increasing component wear, also retards material flow through the plant, thus potentially reducing production rates or increasing electrical demand. Kenco has always specialized in reducing customers’ wear problems. Kenco decided to address this issue by redesigning the tip slightly while also using our unique Tungsten Carbide Impregnation process to greatly enhance wear life.”

Testing began on the new tip in the middle of the 2015 production season. Deliveries to customers began November, 2015.

At 17.375 inches wide, the tip, when mounted on adjacent rows, is wide enough to slightly overlap from row to row, reducing the asphalt buildup common between rows of mixer tips. In testing, the Kenco Longhorn tip cut the mixer floor buildup in half, according to the manufacturer. “Kenco’s Tungsten Carbide Impregnation on our tip allows it to last longer than standard tips while also doing double duty with the cleaning effect.”

• Use this in asphalt mix production.

• For more information, contact Paul McDowell at (916) 782-1796 or paul@kencoengineering.com.

Masaba offers two new conveyor axle configurations. Visit www.masabainc.com.

From Masaba

As of November 2015, bulk material handling equipment manufacturer, Masaba, Inc., Vermillion, South Dakota, is offering folding axles (FA) and Hydra Shift (chainless drive) as options on portable radial stackers and Magnum telescoping conveyors. The new drive options are available on radial stackers up to 125 feet in select belt widths and select 36-inch models of Magnum telescoping conveyors up to 150 feet.

Masaba FA axles are designed to make leveling your conveyor easy on uneven ground and allow for transition between travel and operation in minutes. Axles can be operated simultaneously or each can be raised or lowered independently. They are available in both 2- and 4-wheel drive.

The Hydra Shift drive is designed to simplify the setup process and reduce maintenance time by removing the chain. With Hydra Shift, the operator engages and disengages the drive by flipping a switch on the hub.

• Use this in stockpile management.

• For more information, contact Steve Nelson at (605) 658-8952 or steve.nelson@masabainc.com.

High Chrome wear flights from Maxam Equipment; visit www.maxamequipment.com.

From Maxam

Since March 2015, Maxam Equipment has offered its “High Chrome” dryer flights. Nobody likes to change dryer flights—it is expensive and time consuming. And, if you wait too long to change them, you are losing money in the form of reduced production capacity and lost fuel efficiency. Maxam has solved that problem by introducing its high efficiency flights with replaceable “high chrome” wear fronts. Much of the flight body sees little wear. By designing the flights with replaceable, cast high chrome wear fronts, both the cost and the effort to replace them has been reduced. And, more importantly, your production capacity and fuel efficiency are maintained.

• For more information, contact sales at (800) 292-6070.

Meeker now offers the Liquid Vision system to monitor levels in liquid AC and fuel tanks. Visit www.meekerequipment.com.

From Meeker

Since early 2015, Meeker Equipment, Belleville, Pennsylvania, has offered the Liquid Vision for the asphalt industry. The idea behind it was to allow customers to “see” liquid asphalt levels and fuel levels in their tanks remotely. “This can be done similarly to our hot oil heater’s iPhone and Android app that allows customers to see their hot oil heater functions remotely,” Jeff Meeker said. “This was created due to more and more varieties of liquid asphalt being shipped and stored at an asphalt plant. As we all know, the liquid asphalt is an expensive part of making hot mix. Operators of asphalt plants don’t want to contaminate loads of liquid AC by pumping the wrong product into a tank.

Liquid Vision allows operators and managers to see levels and to know the products they are storing. With the added valve control feature of Liquid Vision, operators can automate all the asphalt valves on the tank farm to provide additional control and assurance of product control.

“Level control is important for a variety of reasons. First, liquid asphalt is expensive. If there is a liquid spill, then expensive product goes throughout the containment area and costs lots of money to clean and to replace. Secondly, it provides a level of safety to the personnel working around the tanks. Third, it allows operators and managers to better manage deliveries of liquid asphalt and to monitor consumption. Fourth, it allows managers to compare liquid levels to hot mix production. This helps determine waste at a plant and unbilled product.”

Meeker prototyped the Liquid Vision system about 2 or so years ago, and started full production about a year ago.

• Use this in asphalt mix production.

• For more information, contact Jeff Meeker at (717) 667-6000 X120 or jmeeker@meekerequipment.com.

Stansteel, Louisville, Kentucky, introduced the Safe-T-Sampler in January to give producers a safe means of extracting hot mix samples at the loadout area. Visit www.stansteel.com.

From Stansteel/Hotmix Parts

Released Jan. 11, 2016, the Hotmix Safe-T-Sampler™ hit the market at the inauguration of Stansteel & Hotmix Parts’ Hotmix University Class for Manager’s Exchange, Louisville, Kentucky. The product was created at customer request to sample final mix product out of truck beds.

“The product has many benefits for operating personnel because it takes them out of the very close proximity to handling asphalt samples with a crude implement,” a spokesperson for Stansteel explained. “The Safe-T-Sampler uses a mechanical arm to insert a probe into the asphalt product in the bed of virtually any size truck used in North America for hauling the hot mix material to the job site.

An asphalt technician doesn’t have to prop a ladder against the truck bed…or lean over the hot product. With the Safe-T-Sampler, it’s a convenient way for the asphalt lab technician to take exacting and deep samples out of the material that has been loaded into the truck either directly from the plant or from the hot mix silos.

“The person taking the samples uses an articulating arm to pull the sample and hydraulically lift, raise and insert the jaw into the hot mix asphalt, and then dumps the material into the sampling chute to be easily handled at ground level. The entire structure and framework permits a convenient and safe working environment and vastly reduces the chance of injury or casualty claims for workman’s compensation or other issues.

There’s no reason for strained back muscles, potential falls, burns or lost time claims or injuries. It helps reduce another potential area of OSHA violations and can even help with a company’s experienced modification rate (EMR). Some of the other major benefits are that it improves the quality of the sample by the ease of taking the sample; more samples can be taken if the state agency desire. This also gives a more accurate temperature reading than just pulling a slight amount of material from the surface only. The sample is consistent the first time and every time.”

Specs:

- Enclosed framework with handrails for the sample technician

- The platform has anti-slip treadplate design

- Articulating, reinforced sampling arm for multi-position reach and inspection has 180-degree independent range of motion; adjustable flow rate to regulate the speed of motion and sample extraction

- Built-in sample chute, sample swivel, folding sample tray

- Hyrdaulic pump and reservoir included

For more information on the Safe-T-Sampler, contact Chris Loher at (800) 826-0223 or cloher@stansteel.com.

In mid-2015, Hotmix Parts released the NiteOwl Advantage plant alert and monitor system to avoid cold asphalt for operators to heat back up at morning start-up. “In addition, the NiteOwl Advantage monitors other items such as electrical power, can initiate a pump reset and many other critical features,” a Stansteel spokesperson explained. “The reason the avoidance of cold asphalt is critical is that any time the hot oil heater or other heat system fails on a plant, and the asphalt cools off and cannot be easily pumped, it can take hours or even a day to get all of the system heated up, the lines unplugged, and the pumps working again.

“The other tremendous advantage of the NiteOwl Advantage is that a company owner, manager or plant operator can call and check on his plant status 24/7 from any location. He can dial into the NiteOwl Alert than can use either regular landline or even a mobile phone device. At that point, he can check on the liquid asphalt temperature circulating in the lines, can get the status of electrical connections, other pumps, even a burglar or alarm system.

Another advantage is that if there is a loss in temperature and it falls below an adjustable setpoint determined for each plant, it will immediately call out to the plant operator and up to three additional phone numbers to alert people. In that way, immediately when the problem happens, the personnel can make a decision to go and repair the problem, or cancel work for the next day, or figure out other ways to solve the issue, which often is a matter of resetting a pump or restarting a hot oil heater.”

Specs:

- Dimensions are 12 ¾” wide x 11” tall x 4 5/8” deep

- Installation is indoor wall-mount, 120 VAC plug, landline telephone jack

- Monitors hot oil temperature

- 230 VAC power

- Aux. contacts for flame relay, circulating pump starter, burglar alarm contacts, etc.

- 2-way communication with 4 programmable numbers for auto call-out

- Optional cell phone call-out interface module if a landline is not available

For more information, contact Gregg Gilpin at (800) 826-0223 or ggilpin@hotmixparts.com.

Since the World of Asphalt show in 2015, Stansteel/Hotmix Parts, has offered the Grizzly twin turbo pump skid assembly to speed up the unloading process of tanker trucks at the asphalt plant. A feature of the product is the leakless design of the pumping assembly. “The main purpose that the product serves is increased plant operation and tanker truck unloading capability, thereby lowering the total cost of delivering a product that has to include a significant amount of freight or hauling costs to get the liquid AC from the terminal to the plant’s AC storage tanks. In fact, with the standard Grizzly twin turbo pump skid assembly, the unloading speed can be 75 percent quicker than the conventional pumps designed and installed on most plants…The other big benefit with the leakless design is avoiding spills at the plant and also the related clean-up time needed by the limited plant personnel.”

Specs:

- Unloading capability up to 350 gallons per minute

- Ultra-rugged unit design with heat-treated helical gears

- Unit fits in and adapts for 3-inch or 4-inch flanged pipe

- The unit option has a screen box strainer assembly

- Leakless pump design includes no-leak drive shaft seals and non-leak lip seal

- Options include: grizzly metering skids and rubber eater heavy duty pumps for polymer and rubberized asphalt

For more information on the Grizzly twin turbo skid assembly, contact Steve Elam at (800) 826-0223 or selam@hotmixparts.com.

The 1292 Material Temperature Capture in Infrared Enclosure add-on from Systems Equipment allows the user to capture the temperature of the material at the time of loading. Visit www.systemsequipment.com.

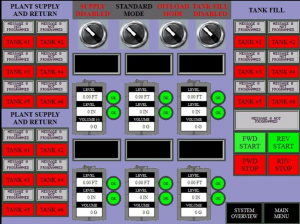

Caption for image saved as PG Systems WIN-LC

From Systems Equipment

For the past couple of years, Systems Equipment, Waukon, Iowa, has made enhancements and offered upgrades to its March 2011 release of its WIN-LC3000 silo loadout system. In early 2015, Systems Equipment received NTEP certification for the program. The basis of the program is a Windows-based system designed to accurately control truck loading, print delivery tickets, store delivery data and print operational reports. Since 2011, add-ons have provided the following:

WIN-LC3000.15 License Plate Photo Capture. This add-on prevents transaction denial by capturing and saving visual documentation of license plates as trucks load. It uses an industrial 2-megapixel network bullet camera for outdoor surveillance with auto-iris capability to protect the lens from damage induced by direct sunlight. It’s furnished with removable IR-cut filter and IR illuminators for day and night quality. Its IP67-rated housing offers protection against rain and dust; its mounting bracket is designed to conceal all cables to prevent tampering and vandalism.

WIN-LC3000.25 Signature Pad for Digital Ticket Management. This add-on includes a 4-inch, backlit screen and built-in AES encryption, RSA signaling and signature biometrics to keep every signature secure. USB line driver hardware is included.

WIN-LC3000.50 Loading Traffic Light Director. This add-on features a PLC that fires the appropriate lane light at the end of the load based on commands sent from the loadout computer.

1292 Material Temperature Capture in Infrared Enclosure (for WIN-LC3000). This add-on offers material temperature capture at the time of load for project specific requirements. The infrared enclosure measures approximately 15 inches high x 25 inches wide x 8 ¾ inches deep. One temperature probe is included to accommodate material temperature capture for one silo.

• Use this for plant controls.

• For more information, contact Dave Enyart at (563) 568-6387 or denyart@systemsequipment.com.

The WIN-LC3000 silo loadout system from Systems Equipment received NTEP certification in early 2015. Visit www.systemsequipment.com.