Vermont Trials Wheel-Path Fix

BY Ian Anderson

The Vermont Agency of Transportation (VTrans), with headquarters in Montpelier, has typically employed common preventive maintenance treatments such as bituminous crack fill sealant, micro surfacing, various seals, ultra thin lays, hot-in-place bituminous overlays, and more. These treatments have proven to be effective.

Their costs, however, can be fairly expensive, depending on the treatment and roadway type. The average winning bid price was approximately $1.6 million to treat an approximate average of 12 miles of state maintained highways from 2009 to 2011. Many state maintenance departments are investigating ways to repair deteriorated roadways at lower costs.

VTrans Operations division has contracted with S.T. Paving Inc., Waterbury, Vermont, through a Category II Maintenance Rental Agreement (CAT II MRA) to address several distresses along four sections of roadway in central Vermont in a cost-effective manner. The project repaved a 40-inch wide area around the right wheel paths in each direction, rather than repave the entire roadway surface.

The goal of the project is to eliminate water penetration, stop further failures, repair and improve the ride, and extend life of the existing pavement. These goals will further improve safety in these areas by:

- eliminating water retention and hydroplaning;

- reducing roughness for cars and bicyclists; and

- eliminating snow retention, thus reducing the amount of salt needed for winter maintenance to clear the roadways.

This report outlines the effectiveness of the process used, as well as the 40-inch skid box on the sections of U.S. Route 2. Site visits with observation of rutting and cracking show an improvement in performance over the period of this study and allow for an extended service life of this roadway segment.

Project Specifics

This project was set in two different locations along U.S. Route 2 in central Vermont. The first began at the Middlesex Maintenance Garage at mile marker 0.0 and extended eastward 3.2 miles. The Federal Highway Administration (FHWA) Approved Work Plan (2012) states that along the first section, there were an observed 114,580 linear feet of ruts and cracks in what was believed to be a Marshall mix design pavement.

The second section began at the intersection of VT Route 100 and extended eastward 2.8 miles. Along the second section, there were 14,113 linear feet of cracks and ruts.

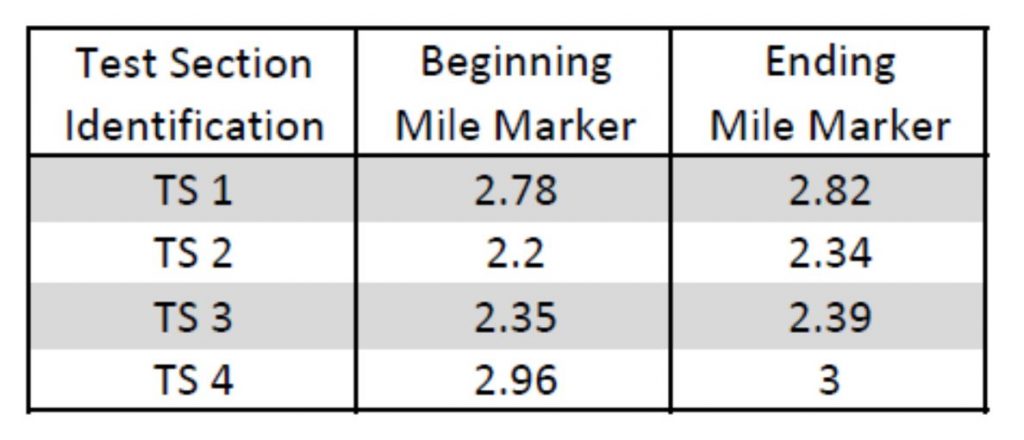

The four test sites were located along the first section. Mile markers for the beginning of each test site were recorded. Cracking and rutting were analyzed in 200-foot sections. Table 1 shows the mile markers of the test site locations.

Table 1. Project Mile Marker Test Site Locations

Test site visits were conducted pre-construction, during construction, post-construction, and twice annually thereafter. The results of each survey were analyzed in the office and the subsequent data recorded. There were only two cracking surveys administered: once before construction and once after construction. Rutting readings were taken every 50 feet, starting with the beginning mile marker for each test section. Readings were taken on the eastbound left and right wheel path and identical readings were taken for the westbound lane.

From top to bottom, the construction of each test section began with milling the rutted wheel path a width of 40 inches and a depth that was necessary to achieve a level surface. A broom followed immediately behind the mill to clean the cut. The S.T. Paving crew then tacked the cut and paved the sections with a 40-inch skid box. The final steps were to lute the edges and roll each section flush with the adjoining pavement.

The pavement used in this study was Type IV 50 Blow Marshall Bituminous Concrete Pavement. The binder used was PG52-34. Construction of the pavement was applied through a five-step process.

- Cold planing at variable depths at a width of 40 inches (to the base of the rutting)

- Sweeping before the application of the emulsion tack coat

- Applying the emulsion tack coat, which was rapid setting RS-1(h)

- Paving at variable depths using the 40-inch skid box

- Rolling for compaction

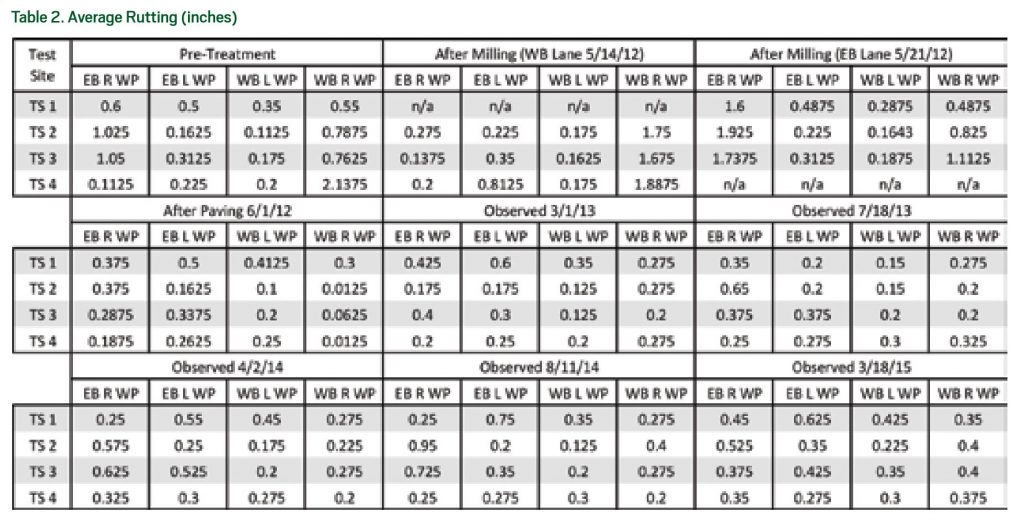

Initial conditions before construction began were taken in spring 2012, then twice during construction—once after the milling of the westbound lane May 14, 2012, and once after the milling of the eastbound lane May 21, 2012. At TS1, the post-milling readings were missed due to the paving operations being earlier than expected.

Test Section 4; Test Sections Observed April 2014

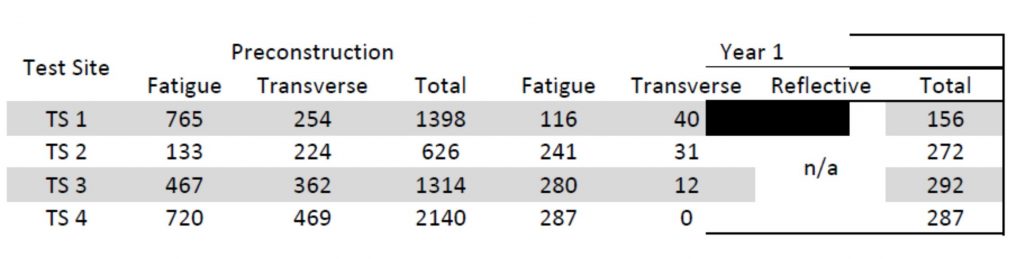

Additionally, at test site 4, there was no repair to the eastbound lane. Table 2 shows the average rutting for each lane in each test site throughout the pre- and post-construction process. The cracking summary pre-and post-construction are shown in Table 3. It is important to note that the cracking results are only for the repaved area in each lane.

Table 2. Average Rutting (inches)

Table 3. Average Cracking (feet)

The site was visited March 2013 and July 2013 to evaluate the repair and to measure rutting in each test site. Photographs and general observations were made at each visit. Figure 2, on page xx, shows each test site during an April 2014 visit. Because the only sections milled and paved were around the right wheel paths for both lanes, the only way to measure the effectiveness of the 40-inch pave box is by comparing the milled sections pre- and post-construction.

- Test Section 1; Test Sections Observed April 2014

- Test Section 2; Test Sections Observed April 2014

- Test Section 3; Test Sections Observed April 2014

- Test Section 4; Test Sections Observed April 2014

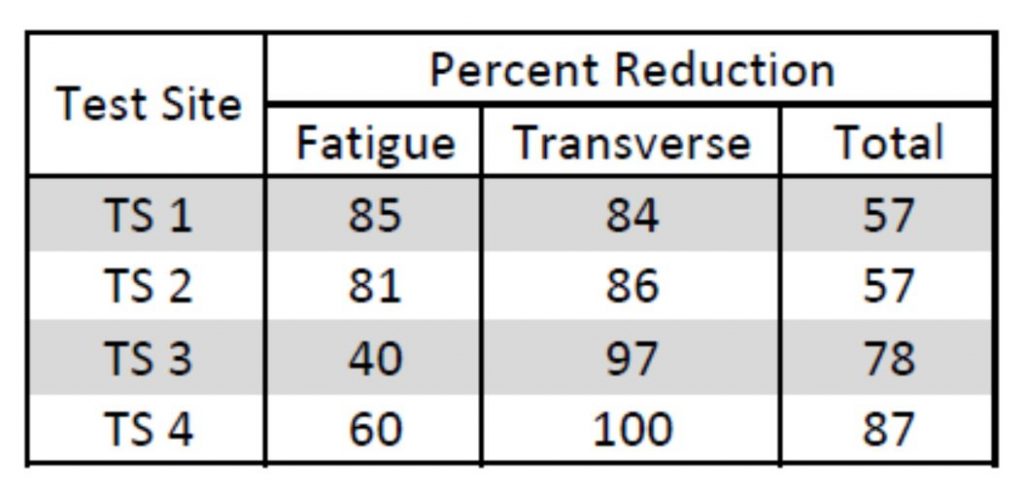

The data suggest the repaved section is performing well and maintained rutting values less than the pre-construction over the test period. The westbound lane also has similar results for overall rutting. Paving for both directions was completed June 1, 2012. The percent reductions of all cracks are shown in Table 4.

Table 4. Cracking Percent Reduction

Test site 2 showed an increase in fatigue cracking post-construction, likely related to the westbound lane fill being underflush with adjacent pavement and the eastbound lane fill being overflush with adjacent pavement.

Test Section 2; Test Sections Observed April 2014

Summary and Recommendations

The purpose of this study was to examine and evaluate the constructability, overall performance and cost effectiveness of using this repair method. Research personnel assessed the existing pavement condition prior to construction to document all distresses, construction practices, and visited the sites annually to document any failures. Overall, the performance of the skid box (repaving only under the right wheel path) was effective in reducing cracking as well as repairing rutting. The data from this project suggest that using the 40-inch skid box to repair distressed sections is a viable alternative to repairing and repaving an entire section of road.

Rutting was significantly reduced and remained so for the entirety of the project; the total cracking within the repaved project sections was reduced as well for the period of this study.

Dr. Ian Anderson is a research engineer with the Vermont Agency of Transportation, Montpelier. For more information, contact him at Ian.Anderson@vermont.gov.