Union Concrete and Construction Gives Buffalo Airport a Lift

BY Gini McKain

The Buffalo Niagara International Airport for the City of Buffalo, New York, received not just a lift, but many lifts of new asphalt on parts of Runway 14-32. The airport also got a new surface course for the entire runway, which measures 5,412 by 150 feet. It took more than 48,800 tons of P-401 surface course with polymer modified asphalt (PMA), P-401 course standard grade asphalt binder, and P-403 bituminous leveling course asphalt for the 120-day contract to improve and rehabilitate the second runway. Taxiways and new drainage will also be improved.

Union Concrete and Construction Corp. of West Seneca, New York, won the contract that started in mid-April of 2017. They also got a hand from a group of manufacturers and companies who worked together to accomplish the strict tolerance requirements of the Niagara Frontier Transportation Authority (NFTA). The airport represents a gateway to Western New York State and portions of southeastern Ontario, Canada, which encompasses the famed Niagara Falls tourist destination. NFTA prides itself on delivering optimal standards of performance to the millions of visitors and residents alike.

It is with that same quality mindset that Union Concrete and Construction Corp., with a history dating back to its founding in 1950 by George Hill, would deliver a smooth surface for NFTA. The firm had worked at other airports, but this was its first runway contract in recent history. A lot of preplanning took place before the decision was made to involve current state-of-the-art equipment in the endeavor.

Service, Service, Service

Union Concrete and Construction Corp. employees went to CONEXPO-CON/AGG in March 2017 to seek out tools for the job, including specific equipment and the contacts to service the equipment and help them reach their goals. With all the equipment and ancillary firms within walking distance of one another in Las Vegas, Union managers were able to make their selections.

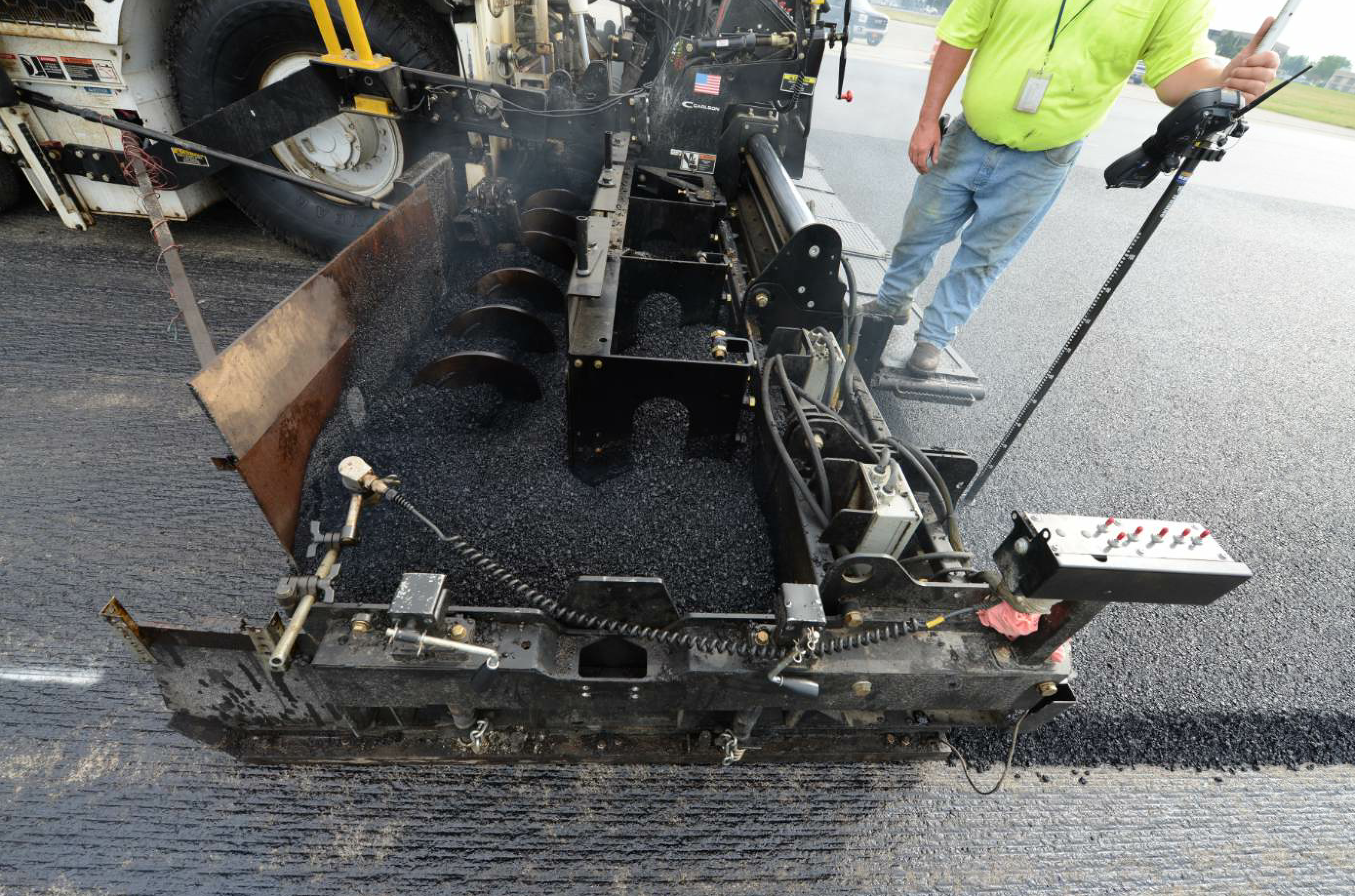

In this case, they decided that local dealer Tracey Road Equipment would bring its Roadtec RP-190e paver with a Carlson EZR2 rear mount screed to the project. The RP-190e paver came equipped with MOBA-matic II grade and slope automation already installed. Then the dealer contacted SITECH Solutions, a liaison and software company affiliated with Trimble® Inc., Sunnyvale, California.

The service aspect of the equation continued on site, once the equipment was delivered. Tracey Road’s service technician, John Messbauer, supported several service technicians from Carlson Paving Products who came from across the country to properly connect the screed.

The Trimble 3D Paving PCS900 Control System included the Universal Total Station on-site with the mast-mounted target on the tow arm of the paver with a Trimble MT900 prism on top and a slope sensor. A Trimble CB460 control box displays the 3D design model and the position of the screed.

Strategic Project Manager Anant Patel, with MOBA, fine-tuned the 3D leveling and quality control systems for the paver, which are compatible with the Trimble 3D PSC900 Paving Control System. SITECH Northeast helped install the components required to upgrade to 3D, along with integrating a smooth flow from hardware, and software design to the Trimble Universal Total Station setup.

After several days of installation, and actual hands-on practice by paving the required test strips with Union crews that would use the equipment, rehabilitation could begin. Roadtec would again service the contractor by bringing Dale Bloodgood, the regional service technician, to overlook and tweak anything needed while the crew paved up to 26-foot-wide passes during the surface course paving.

Project

The Buffalo Niagara International Airport for the City of Buffalo, New York, received a new surface course for the entire runway, which measures 5,412 by 150 feet.

According to Union Paving Foreman Jim Stayer, the project had multiple lifts in some areas; a single 3-inch mill-and-fill in other areas. Paving parameters depended upon how deteriorated the existing pavement was or how much of a profile change was needed. “Existing condition” also determined how long each pass would be; they varied up to 2,000 to 3,000 feet long. Other areas, like the taxiways, were much shorter, meaning more sections—or phases—could be done in the course of a normal 12-hour shift.

“Mostly the sections had good phase lines where it made sense to phase to, and then switch to, another phase because the paving was done in sections,” Stayer said. “Sixteen hundred feet had to be completely rehabilitated to subbase on one end of the runway before intersecting with Runway 5/23. It would be 4 feet deep, which included rubblization of 27,000 square yards, full depth construction and repairs and full depth HMA pavement construction at the long runway stretch.

“Full depth blacktop included 8 inches of base course done in two lifts using 16,200 tons of P-401 HMA, and 4 compacted inches of surface course done in two lifts of 2 inches each.

“For 400 feet, there was a transition from full depth rehabilitation to just a surface course,” Stayer continued. “It was a profile change because you came from nothing up to 4 feet of profile change, all 150 feet wide. We had no problem, and used the 3D System with our Roadtec paver and Carlson screed laying 18 ½-foot wide passes throughout the base courses and first surface course.

The Buffalo Niagara International Airport for the City of Buffalo, New York, received a new surface course for the entire runway, which measures 5,412 by 150 feet.

“The RP-190e paver was always our primary laydown machine, but we had our older Cedarapids paver making passes on the outside lanes using a stringline where it wouldn’t be damaged from equipment. At least 75 percent of our paving was done with the Roadtec paver and the Trimble 3D system.”

As Stayer described, paving was done in echelon wherever possible, to prevent cold joints. Longitudinal joints could not be exposed for more than four hours. If the surface temperature of the mat cooled to less than 175º F, the crew was required to cut the joint back 3 to 6 inches for a clean, uniform vertical edge before matching it.

The Trimble 3D Paving PCS900 Control System included the Universal Total Station on-site with the mast-mounted target on the tow arm of the paver with a Trimble MT900 prism on top and a slope sensor. A Trimble CB460 control box displays the 3D design model and the position of the screed.

The solution to that issue was simple, but logistics were more challenging. They could never stop the pavers during their designated phases—no matter how long the pass. In some instances, passes were 3,000 feet long. Having done their homework, Stayer said they worked it out like this:

“We try not to stop the machine at all from paving during the whole pass, including when going over 30-inch-wide raised concrete/light bars that had to be covered before paving. That meant the paver was traveling about 10 to 12 feet a minute, non-stop, with mobile transfer machines supplying the pavers. The transfer machines were MC-330 Blaw-Knox units supplying the material from 28 to 34 trucks of tri-axle or Flow-Boy configurations, depending upon our several haul truck suppliers. A round of trucks would be 600 to 650 tons of asphalt from the close-by plant. The plant has the capacity of 300 tons an hour, but with 1,200 tons of asphalt in silos before actual paving, there was no shortage of asphalt coming to the pavers before the end of the day. When we did the surface course, we were putting down 3,700 to 4,000 tons a day of the P-401 surface course, while paving 25 feet wide for much of the 31,200 tons needed.”

Rollers used were a combination of Hamm HD140, Sakai and Caterpillar steel drum rollers working behind both pavers. The Cedarapids paver used the stringline on one side for grade and slope while matching the joint placed by the RP-190e in front of it for the other side. The older paver was not Trimble/SITECH compatible. The roller operators compacted the joints as one complete lift.

Equipment Configurations

A lot of preplanning took place before the decision was made to involve current state-of-the-art equipment in the endeavor.

According to Roadtec’s Bloodgood, the RP-190e paver was used for several features. It has a 13-inch high conveyer opening for excellent throughput with independent drive. The space between the conveyers has been minimized, which allows mix to be conveyed out as one uniform flow, reducing segregation.

The Carlson EZR2 rear mount screed was used for its weight and 4-inch chrome rods tightly fixed to a heavy-duty tubular frame, providing the extensions optimal rigidity. Large adjustable slide blocks and bushings are designed to eliminate flexing at wider widths, which was important for laying the surface course up to 26 feet wide. A 2- and 3-foot screed section was bolted and leveled on each side, with three 2-foot strikeoffs affixed, also added on each side. Six-foot auger extensions were attached to make sure the asphalt material went out to the endgates. The pre-strikeoffs kept a nice head of material all the way across. Screed vibration for additional compaction throughout was maintained during all paving.

The MOBA-matic II is a flexible leveling system for pavers that enables control of layer thickness and slope of the screed, in this case for a 1 percent slope across the width of the runway, with an ultrasonic sensor.

The Carlson EZR2 rear mount screed was used for its weight and 4-inch chrome rods tightly fixed to a heavy-duty tubular frame, providing the extensions optimal rigidity.

“Our tolerances were very tight,” Stayer said. “We have a quarter of an inch in tolerance for straightness and half an inch tolerance for elevation, across the board. We went with the SITECH system because we didn’t want to put up a lot of stringlines that could be damaged with moving equipment across the 150-foot-wide runway. Trimble is compatible with SITECH and has an accuracy of a millimeter. There is no other product on the market today that is approved by the airport. Morning measurements had us running .0004 of an inch accurate, and even better other mornings.

“There are at least five guns or total stations that are read to about 400 feet,” Stayer continued. “As we pave, we get a reading from the first station and when we get close to the outer 400-foot range, I switch to the next gun [total station] while still paving.

The measurements are sent to the target that is mounted on the paver. In this case, to not interfere with trucks or equipment in range, we have set it 14 feet high to receive the information. When the Trimble system is set up, it knows where it’s at and the paver knows what the screed height is. It controls the screed elevation through the guns that are placed alongside of the runway. The total station signals basically give us a finished grade and the automation on track.”

As Stayer described, paving was done in echelon wherever possible, to prevent cold joints. Longitudinal joints could not be exposed for more than four hours.

The Trimble 3D Paving PCS900 Control System included the Universal Total Station on-site with the mast-mounted target on the tow arm of the paver with a Trimble MT900 prism on top and a slope sensor. A Trimble CB460 control box displays the 3D design model and the position of the screed. There are also design files stored in the box on the paver for guidance. Through radio commands, the grade and slope could be used to move the tow arms for the screed to adjust accordingly.

Results

The project was done on time and with no discernable issues. “We wanted to go with the stringless system, for economy and expediency,” Stayer said. “We wanted to go with the SITECH system and then went with the other equipment compatible with it. We have had very good support from Roadtec and the other equipment manufacturers and the dealer, Tracy Road Equipment. There was a learning curve for us all on the whole system used, but once we figured it out, everything has been very accurate. The paver and screed were also very user friendly and with the 3D system worked out very well.”