Sequester Carbon in Road Repairs

BY Leigh D’Angelo

Modern Hydrogen hosts pilot project in San Antonio

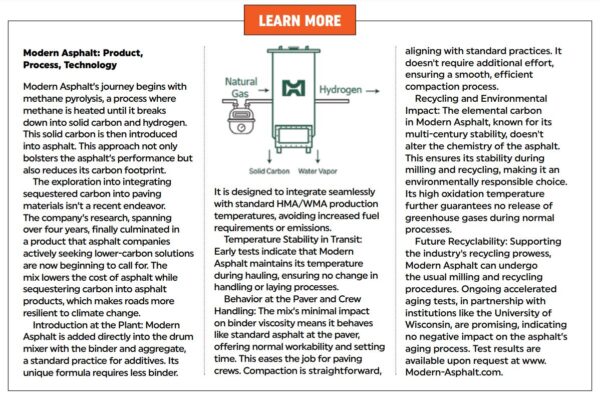

In a move blending innovation with environmental stewardship, San Antonio recently embarked on a project to not only fix potholes, but to also enhance its commitment to sustainable practices. This time it used Modern Asphalt, which is a product developed by Modern Hydrogen, Bothell, Washington. The product is characterized by its low embodied carbon as well as its incorporation of sequestered carbon into traditional asphalt.

Key Points:

-

Modern Asphalt uses less binder than traditional asphalt. This lowers the amount of embodied carbon while also cutting costs.

-

Municipal leaders and government officials are leading a push for lower-embodied carbon asphalt projects nationwide with asphalt manufacturers willing to innovate.

-

Solid carbon, which has been stripped from natural gas, is sequestered into Modern Asphalt.

-

San Antonio, the first place to use sequestered carbon in asphalt on public roads, is making sure Modern Asphalt continues to meet specifications in higher temperatures without sacrificing cold-temperature performance.

San Antonio’s Project

Old Fredericksburg Road, usually a mundane backdrop for routine maintenance, transformed into a stage for sustainable innovation. Bexar County, in collaboration with Road Recyclers of Austin and Modern Hydrogen, launched a pilot project leveraging Modern Asphalt for pothole repairs. Mothusi Pahl, Modern Hydrogen’s vice president of business development and government affairs, said: “This serves as a model that will capture the attention of the entire nation.”

Team members from Bexar County, Road Recyclers and Modern Hydrogen collaborated to transform routine road repair into a sustainability demonstration.

The project’s goal transcends the mere repair of road surfaces; it explores the viability of sequestered carbon-amended asphalt in enhancing durability while promoting eco-friendliness. Tony Vasquez, Bexar County DPW director, emphasized the project’s dual focus: “If you have a product that’s eco-friendly but doesn’t work, you can’t use it. But one of the benefits of adding sequestered carbon to the mix is it makes it stronger.”

Advantages and Applications

Modern Asphalt has multiple applications. For hot-mix asphalt (HMA), the sequestered carbon mix acts as an extender, allowing for less binder material use without compromising quality. It’s recommended for low to high traffic volume pavement, dense-graded and asphalt shingle mixes.

For cold-patch mixes, the sequestered carbon is a stabilizer and is designed to improve binder stability in high temperatures. The mix is used for rutting repairs, manholes and utility cuts.

The benefits extend beyond road repairs. The sealer pigment in Modern Asphalt adds a depth of color to asphalt emulsions, enhancing visual appeal, and can be used in slurry seals, fog seals, tack coats and chip seals.

This versatility positions Modern Asphalt as a frontrunner in various asphalt applications. Shane McDade, CEO of asphalt manufacturer Road Recyclers, highlighted the uniqueness of the product: “By putting their captured carbon into the patch, we are locking down carbon otherwise going into the atmosphere, so it’s truly green.”

Team members from Bexar County, Road Recyclers and Modern Hydrogen collaborated to transform routine road repair into a sustainability demonstration.

Practical Implications and Observations

In San Antonio, the performance of Modern Asphalt under extreme temperatures is under scrutiny—for good reason. The summer of 2023 broke heat records in the Alamo City with 64 days of 100-degree weather, according to the San Antonio Express-News.

As temperature can impact pavement performance, San Antonio offers an ideal testing ground for Modern Asphalt. Bexar County will closely monitor Modern Asphalt for distress such as pavement blowups, shoulder rotation, thermal cracking, rutting, shoving and corrugation, which the Federal Highway Administration (FHWA), reports can all be caused by environmental conditions.

Step 1 is to saw cut and remove potholed or damaged areas along Old Fredericksburg Road in San Antonio. All photos courtesy Modern Hydrogen

Early observations of Modern Asphalt suggest enhanced durability and a reduced environmental impact. Local stakeholders and public works officials are closely monitoring these developments.

“We can increase traffic loading performance with our mix,” said Michael Baba, a product manager at Modern Hydrogen. “The project’s success will pave the way for widespread adoption, potentially revolutionizing the way cities approach HMAs and road maintenance.”

Step 2, after cleaning the area to be patched, is to fill it with the coldpatch mix containing the Modern Asphalt product. Crew members work the material by hand the same as any traditional mix.

For the world’s most recycled product, ensuring asphalt’s recyclability remains unscathed is a top priority. Modern Hydrogen is attuned to the cities and manufacturers who have experienced workability or recyclability issues with some eco-friendly materials in the past.

Modern Asphalt doesn’t require higher temperatures in its process. DOTs and other agencies can review ongoing accelerated aging testing data collection from research firms such as the University of Wisconsin Modified Asphalt Research Center.

Step 3 is to compact the area. Crew members on the San Antonio project reported no difficulties with this step.

Although the company says data shows Modern Asphalt maintains its stability, the project leaders say to characterize its performance and do accelerated aging tests to be sure, they need more partners to work with. The company continues to do binder/oxidative aging testing, which so far has shown no negative impacts.

Broader Impact and Future Outlook

We are at a critical juncture in the pavement industry’s evolution, coinciding with the federal push for clean construction projects. The Biden-Harris Administration’s November 2023 announcement of a $2 billion investment in clean energy construction projects underscores the growing importance of low embodied carbon materials in all infrastructure development and is pivotal to the plan to reduce emissions by 40% by 2030.

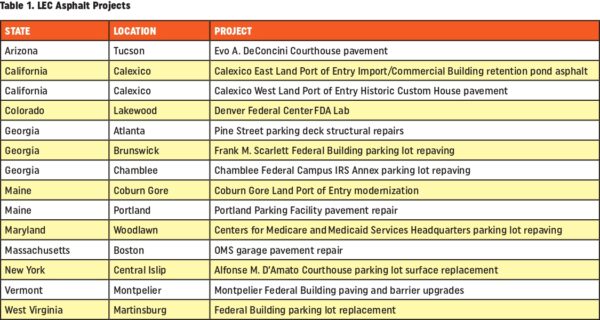

Specifically, the U.S. General Services Administration announced 153 federal government building projects that will prioritize the procurement of low-embodied carbon (LEC) materials. 81 of those projects are slated to share $384 million dedicated to LEC asphalt. Asphalt-only projects are in Table 1.

Modern Asphalt offers substantially lower levels of embodied carbon, which aligns with the government’s “call for offer or commitments to furnish IRA-eligible materials with the lowest available global warming potential values for each applicable material type,” as described in LEC acquisition criteria resources.

CEO and Co-Founder of Modern Hydrogen Tony Pan heralds this approach, saying, “The government, at all levels, should be leading by example and implementing clean energy and low-carbon strategies at government facilities and in public infrastructure; low-carbon roads, runways, and more should be mandated or incentivized for government suppliers.”

Modern Motorways: From Local Lanes to Nationwide Networks

As cities and regions across the nation grapple with the challenges of sustainable urban development, San Antonio’s pilot with Modern Asphalt presents a compelling case study. Its success could signal a new era in road construction, marrying environmental responsibility with practicality and performance.

The San Antonio pilot project is more than just a local initiative; it’s a beacon of innovation in the asphalt industry. By embracing Modern Asphalt, the city isn’t just repairing roads; it’s paving a path toward a more sustainable future. As this project unfolds, it may very well set a new standard for urban infrastructure, demonstrating that ecological responsibility and high-quality road construction can, indeed, go hand in hand.