Ray-Tech Infrared’s AGG/RAP Heater System

BY AsphaltPro Staff

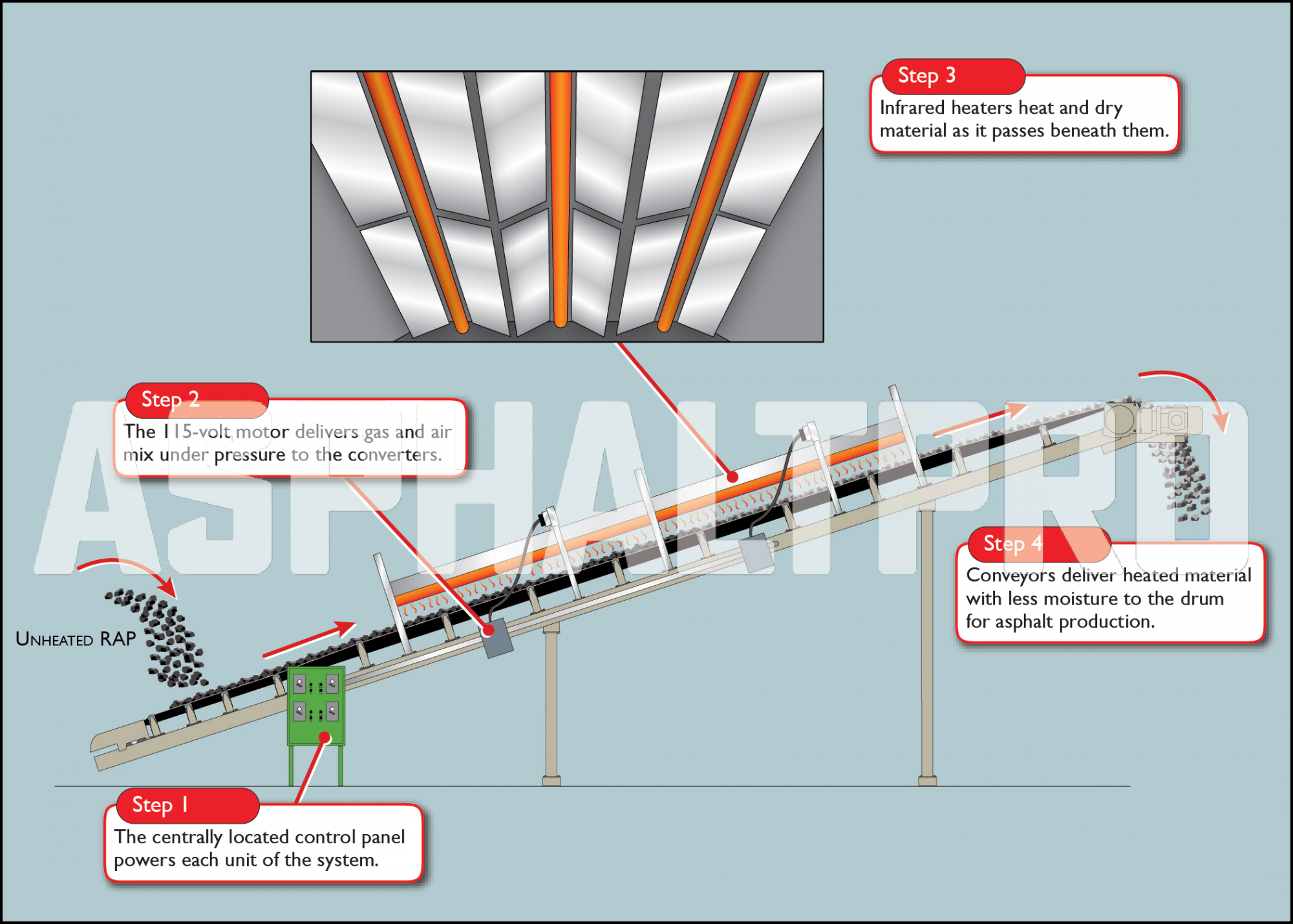

At the asphalt plant, moisture, emissions and fuel inefficiency are the enemy. To help reduce moisture in reclaimed asphalt pavement (RAP) being fed to the plant, the team at Ray-Tech Infrared Corp., Charlestown, New Hampshire, has introduced its AGG/RAP heating system. According to the manufacturer, it is a clean burning fuel efficient infrared heating system designed to heat and dry aggregates and RAP as part of the asphalt mix production process. Here’s how it works.

Ground personnel install the structure, composed of multiple Ray-Tech infrared heating converters, over a high-temperature conveyor belt. The plant operator can operate each unit of the system independently from a centrally located control panel, which supplies power to each unit.

A heavy duty, 115-volt blower motor delivers propane gas and air mix under pressure to the converters. Each chamber has eight stainless steel infrared converters to preheat the material and reduce moisture. The aggregate—or RAP material—passes mere inches beneath the heaters, as the conveyor belt carries it toward the drum or mill for production. As the preheated material enters the drum or mill, the efficiency of production is improved since the materials enter in a preheated state with the reduction of moisture well under way.

The result can be improved operational cost, energy consumption, production capacity and air quality.

For more information, contact Jeff LeClair at (800) 884-2072 or jeff@raytechinfrared.com.