Process Heating Company’s Lo-Density All-In-One Heater Kit

BY AsphaltPro Staff

When it comes to plant priorities, reducing emissions and reducing costs are often high on the list. That’s why Process Heating Company of Seattle offers the Lo-Density All-In-One Heater Kit. The system provides heat to the asphalt tank and hot oil for the plant, while reducing emissions and the accompanying need for expensive stack permits, according to the manufacturer. Here’s how it works.

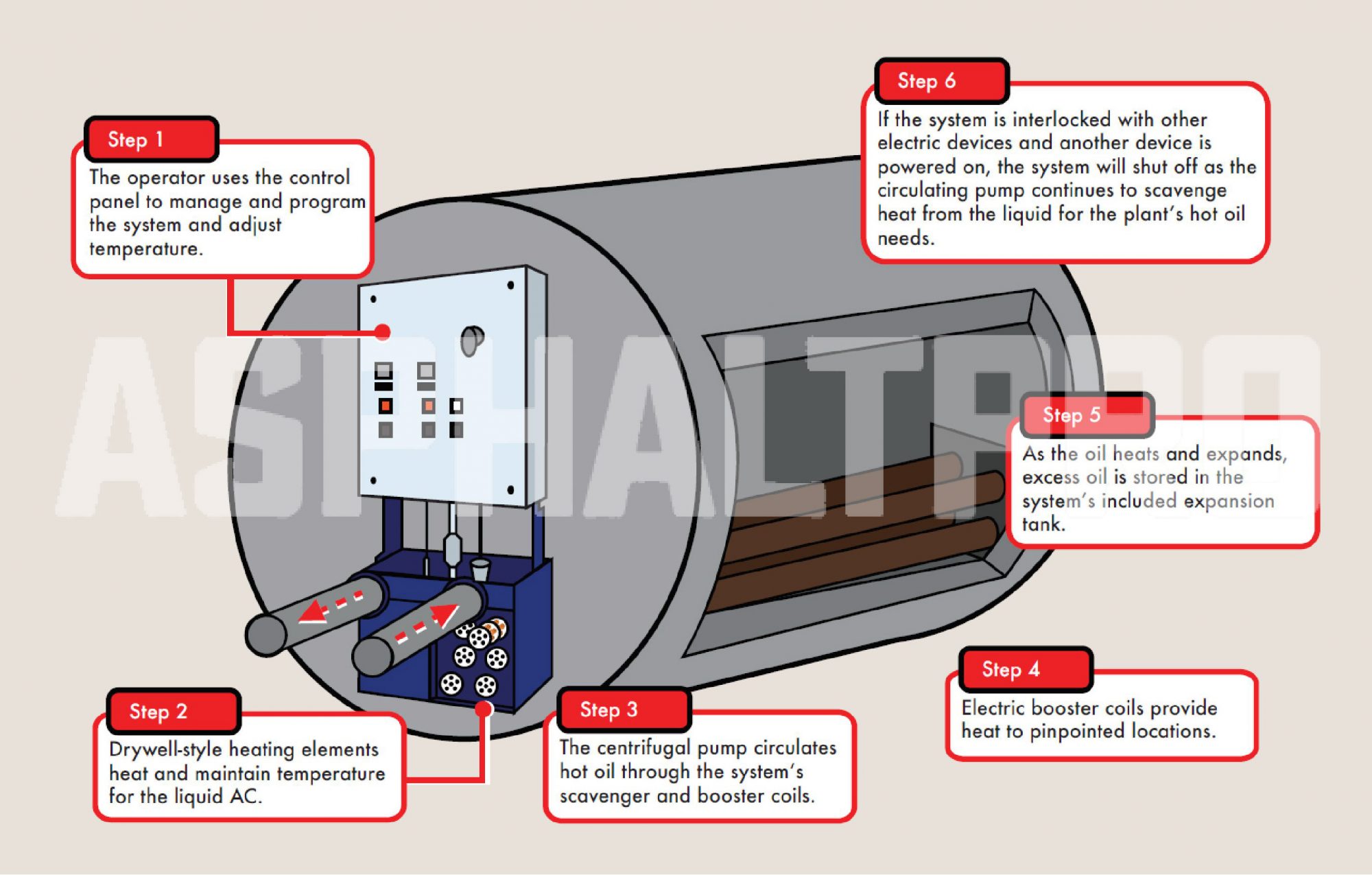

The operator controls the entire system with the included weatherproof industrial control panel to manage temperature and other system variables, program the system for early morning startup, and more.

Upon startup, the system’s drywell-style electric heating elements provide and maintain heat to keep the liquid AC at the correct temperature. At the same time, a high-temperature centrifugal pump will circulate oil first through scavenger coils for quick heat, and then through thermostat-controlled electric booster coils, to provide hot oil to heat pumps and valves, jacketed lines and more. The booster coils provide heat to pinpointed locations and can elevate the temperature of the oil above the controlled asphalt storage temperature, if required.

Due to their location within a drywell, the heating elements can dissipate controlled heat as low as three watts per square inch to reduce coking and damage of the AC and oil.

As the oil heats and expands, excess oil is stored in the system’s included expansion tank, with limited exposure to air, to extend the service life of the oil. The expansion tank also acts as a way to take in and release air as the oil level rises and falls.

If another electric-powered device, such as an exhaust fan, starts up at the plant, the heater—which can be interlocked with other electric devices—will shut off to reduce energy demand. Meanwhile, the circulating pump will continue to run, scavenging heat from the liquid for the plant’s hot oil needs.

In the event that the drywell-style elements need to be serviced, because they are accessible from outside the system, there’s no need to drain the tank.

For more information, contact Rick Jay at (866) 682-1582 or rick@processheating.com.