Pipe It Safely with New Leak Detection Tech

BY Caleb Radford

A pipeline assessment tool capable of leak detection and imperfections in water networks is helping to locate weak spots before they become costly pipe bursts. P-CAT is a condition assessment technology that allows pipeline owners and operators to accurately identify defects and develop cost effective solutions. Consider the applications of this new technology for pipes in asphalt terminals and tank farms.

It was developed by researchers from the University of Adelaide in South Australia and commercialized by water management company Detection Services. P-CAT co-developer Martin Lambert said the technology was able to detect leaks, pipeline weak spots and blockages.

“What we are doing is using little pressure waves in a pipe and essentially we look at the reflection,” Lambert said. “The wave travels down the pipe and when it hits a change in the pipe—a leak, a change in the wall thickness or a deteriorated section of the wall—it sends a reflection back to the sensors and you can tell where the defect is.

“It works a bit like a radar system at an airport where a radar pulse hits a plane and then comes back with a reflection. Then it’s a matter of determining or understanding what you are getting back.”

The technology creates a controlled water hammer event where a small pressure transient is directed into the pipeline and is able to run for up to [1.24 miles] 2km.

Sensor fittings are placed along the pipeline about every kilometre, which records the reflection of the wave as it passes each fitting.

The wave speed slows down when sections of the pipeline are corroded or the wall thickness is reduced – it is able to determine and analyze the change in thickness down to about [0.007 inches] 0.2mm.

P-CAT breaks up the data collection phase into multiple short stages to retrieve highly accurate information and collates a total of about [1.9 to 3.1 miles] 3 to 5km of data per day.

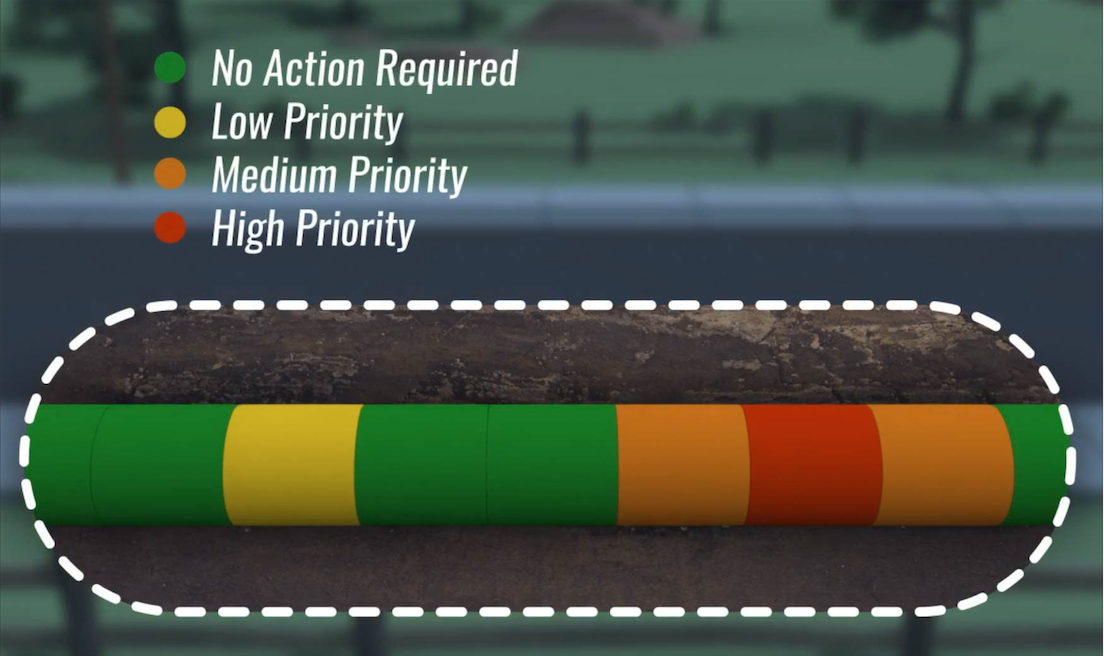

The results are then analyzed and the identity of faulty sections of pipeline are determined.

Business Development Manager Kevin Jamie said P-CAT could save clients millions in replacement costs.

“The primary benefit of P-CAT is determining pipe wall thickness,” Jamie said. “It is a very common practice worldwide for water utilities that pipes have an internal cement lining—an erosion prevention lining—we will determine if there are any air or gas pockets in the internal lining.

“The primary benefit of P-CAT is determining pipe wall thickness,” Jamie said. “It is a very common practice worldwide for water utilities that pipes have an internal cement lining—an erosion prevention lining—we will determine if there are any air or gas pockets in the internal lining.

“That’s important because an air pocket is not only a partial blockage or restriction, but you will find air or gas pockets will increase the corrosion rates.

“We could save clients replacing the whole pipeline, when they actually only need to replace a small section of it.”

Detection services have successfully tested more than [373 miles] 600km of pipeline around Australia and New Zealand using P-CAT. Jamie said the company was also in talks to export the technology to the United States, China, India, Singapore and Europe in 2017. Last month Detection Services was awarded the TRILITY Planning & Delivery Award for its pipeline condition assessment technology at the 2016 Smart Water Awards in South Australia’s capital Adelaide.