How P-401 Spec Changes Affect You

BY Jon Young

Editor’s Note: In the August Hawaii Asphalt Paving Industry (HAPI) newsletter, Jon Young shared a summary of the Airfield Paving Clinic Workshop (APCW) held July 11 and 12 at the Daniel K. Inouye Airport Conference Center. The goal of the workshop was to discuss changes to the Federal Aviation Administration (FAA) Advisory Circular (AC) 150/5370-10H, which is more commonly referred to as the P-401 spec. The article is reprinted with permission and goes over the changes, which were issued Dec. 21, 2018, and discussed at the workshop.

Changes to the P-401 spec have placed more emphasis on two items: quality control (QC) and tack coat.

QC is an essential component of a project. The updated spec makes the QC program, which formerly was an incidental cost, a separate pay item. The QC program includes all required sampling and testing by the contractor, and now also requires the contractor to facilitate a quality control/quality assurance (QC/QA) workshop.

Required participants in the QC/QA workshop are the engineer, resident project representative (RPR), contractor, subcontractors, testing laboratories and owner’s representative. The workshop must be held prior to start of construction.

The other change stresses the importance of tack coat by making it a separate pay item. Tack coat is the “glue” that is applied between two layers of asphalt. Adequate bonding between lifts of asphalt pavement is critical for the completed pavement structure to behave as a single unit and provide adequate strength.

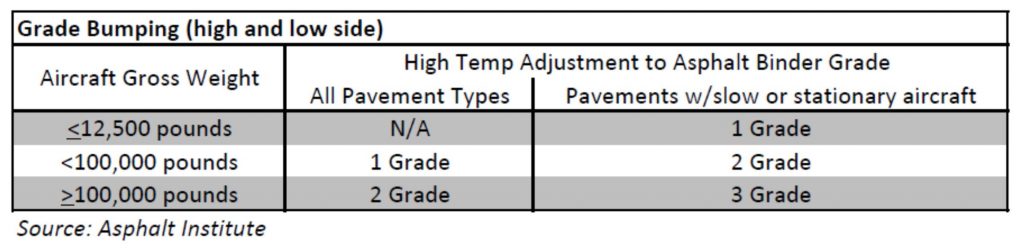

Table 1. Guidance for PG selection includes grade bumping

Other changes to the P-401 spec include the following items.

- Compaction of the mat will now be measured as a percent of Total Maximum Density (TMD) versus what it used to be, which was a percent of lab bulk density. This makes it consistent with the highway industry.

- The spec now offers improved minimum thickness guidance. The recommended minimum construction lift thickness for Gradation 1, 2 and 3 is 3 inches, 2 inches and 1 ½ inches, respectively. Gradation 3 is intended for leveling courses. If the contractor wishes to use Gradation 3 in other locations, the contractor will need to get FAA approval to do so.

- Gradation plans have been adjusted to match the military airfield specifications.

- For rut testing/evaluation, there is a new loaded wheel test requirement for mix design. The default uses an Asphalt Pavement Analyzer (APA) with 250 psi hose pressure at 64 degrees centigrade in accordance with AASHTO T340. The rutting must be less than 10 millimeters at 4,000 passes. An alternative method also uses the APA, but at 100 psi hose pressure at 64 degrees centigrade in accordance with AASHTO T340, the rutting must be less than 5 millimeters at 8,000 passes. Another alternative method uses the Hamburg Device in accordance with AASHTO T324 and the rutting must be less than 10 millimeters at 20,000 passes.

- Updated guidance on PG selection; there is an additional grade bump (See Table). The base grade is based on climate only; there is no bumping for traffic. When bumping a grade, add a PG Plus test if the upper temperature limit is 92 or greater (if there’s a modified binder). Use Asphalt Institute’s binder spec database for reference.

A handful of the most important slides from additional presentations are available if you click here.

APCW Teaches the Specs

Guy Ischinotsubo, engineering program manager for HDOT—Airport Division, addressed about 65 attendees at the APCW event. Photos courtesy Lynn Young, HAPI

The workshop attracted about 65 people from the Hawaii Department of Transportation—Airports Division, design consultants, construction managers, inspectors and paving contractors. The workshop covered many aspects of asphalt pavements, including significant changes to the P-401 spec that were made in the recently released AC 150/5370-10H.

Day 1 topics included an overview of the workshop, aggregates, asphalt binder, hot-mix asphalt mix design and contractor quality control program. The class exercise was a contractor mix design submittal review.

Guy Ischinotsubo, engineering program manager for HDOT—Airport Division, addressed about 65 attendees at the APCW event. Photos courtesy Lynn Young, HAPI

Day 2 topics included owner acceptance testing and percent within limits; prime coat, milling, and patching; tack coat; paving operations; compaction operations; and longitudinal joints. The class exercise was a pay factor analysis.

Attendees received professional development hours certificates at the end of the workshop.