New Paving and Pavement Maintenance Equipment This Season

BY AsphaltPro Staff

While many original equipment manufacturers (OEMs) launched new equipment models during CONEXPO-CON/AGG 2017 in Las Vegas March 7 through 11, some companies still have new components, upgrades, tech packages and even new iron coming to market now that we’re into the heart of construction season. For example, if you’re looking for a puncture-proof radial tire specifically for compact loaders, the research and development team at Magna Tyres Group out of The Netherlands, introduced its new Magna MA11 Tyre with an E2/L2 tread pattern for road, residential, commercial and landscaping applications April 6. The manufacturer says its high-tech casing reduces heat build-up inside the tire, which offers lower fuel consumption and prolonged service life. To contact someone about the Magna MA11, you email info@magnatyres.com.

Another example of post-CONEXPO launches is the commercial cold planer series from Caterpillar—the PM300s. The series will be available in September.

Even the peripheral equipment you must have on every job has some news. Schwarze Industries out of Huntsville, Alabama, for instance, announced in early April a free 5-year/5,000-hour extended warranty program on its A7 Tornado, A8 Twister and A9 Monsoon sweeper engines. The company says the extended warranty is portable and transferable, and covers “reasonable” travel expenses for John Deere service dealers so you can get help virtually anywhere in the United States and Canada. For more information on that, you have to contact your local Schwarze dealer or call Schwarze direct at (800) 879-7934.

Check out some other paving and pavement maintenance related products and services that have hit the marketplace this year to enhance your bottom line.

Allmand Bros.

The smallest unit in the new Maxi-Power line from Allmand Bros., the MP25, pictured here, uses a 33.3-horsepower engine and provides 20 kilowatts of prime power.

Allmand Bros. Inc., Holdrege, Nebraska, a subsidiary of Briggs & Stratton Corporation, expands its product offerings with the introduction of Maxi-Power™ mobile generators. The line includes seven maneuverable generators ranging in output from 25 to 50 kilovolt amps. The generators feature a heavy-duty, oversized alternator with separate excitation winding to handle large motors and variable loads. The automatic voltage regulator is designed to adjust quickly to provide stable and consistent voltage for powering sensitive equipment. Maxi-Power generators switch between 50- and 60-Hertz frequencies. All models adjust between 120, 240 and 277 volts in single-phase power, and 208, 240, 415 or 480 volts in three-phase. An electronic governor maintains engine speed independent of the load. The Maxi-Power series features programmable start and stop capabilities for use as a standby system.

Features include a large-capacity fuel tank, external fuel connections, a high-capacity cold start battery, a dual filtration system, durable 15-inch tires and an adjustable couple channel for towing ease.

For more information, contact (800) 562-1373 or info@allmandcom.

ALLU

End product size is defined by the space between the combs of the new ALLU TS® drum assembly construction.

ALLU Group of Teterboro, New Jersey, has introduced the patented ALLU TS® drum assembly construction, which lets customers reposition standard screening blades to perform multiple jobs with one unit. The core of the ALLU TS technology is the configuration of the screening blades that spin between the screening combs. The end product size is defined by the space between the combs. Because the screening combs carry most of the material weight, the drums and bearings experience less impact and load.

The TS drums are available with two different blade types: standard for screening applications; axe for crushing or shredding. Available blade sizes include: 0.63/1.26 inch, 0.98/1.97 inch and 1.38 inch. The TS assembly is available in seven different models for 17.6- to 49.6-con excavatorys and 7.7- to 33-ton wheel loaders.

For more information, contact ALLU Group at (800) 939-2558 or visit www.allu.net

BOMAG Americas

The RS500 from BOMAG Americas has a forward operating speed of up to 164 feet per minute, and uses variable rotor speeds from 100 to 180 rpm to match rotor speed to the application.

BOMAG Americas, Ridgeway, South Carolina, has released the RS500 reclaimer with FLEXMIX. The extra breaker bar assemblies and an additional variable-position mixing door within the rotor chamber of reclaimer/stabilizer are designed to allow contractors to achieve consistent and controllable gradation with a simple toggle switch. The optional FLEXMIX, adjustable door is located above the rear discharge door to provide flexible mixing of material inside the rotor chamber. Check out the Here’s How it Works feature on page xx for a full description.

For more information, contact Tim Hoover at (660) 580-0350 or tim.hoover@bomag.com.

CASE Construction Equipment

The new DV45CC asphalt compactor from CASE is designed for groundline serviceability.

CASE Construction Equipment, Racine, Wisconsin, launched the new DV45CC combination vibratory roller in March. The new vibratory roller is designed to compact with the front drum and deliver a smooth finish with the rear pneumatic tires. An offset drum with tapered edge and high curb clearance is designed for tight spaces; adjustable scrapers, an automatic vibration control system and a pressurized water system offer smoothness for asphalt applications. It features an operating weight of 10.296 pounds and a drum width of 54 inches.

The DV45CC has a 40.8 horsepower Tier 4 Interim engine. It features standard dual amplitudes of 0.01/0.21 inches and dual frequencies of 2,700/3,420 vpm. The automatic vibration control system provides automatic or operator-controlled start and stop to the drum.

The DV45CC features an iso-mounted operator platform to minimize vibration and reduce operator fatigue. A standard lateral-sliding seat provides the operator visibility to the drum edge on both sides of the machine.

For more information, visit CaseCE.com.

Hamm

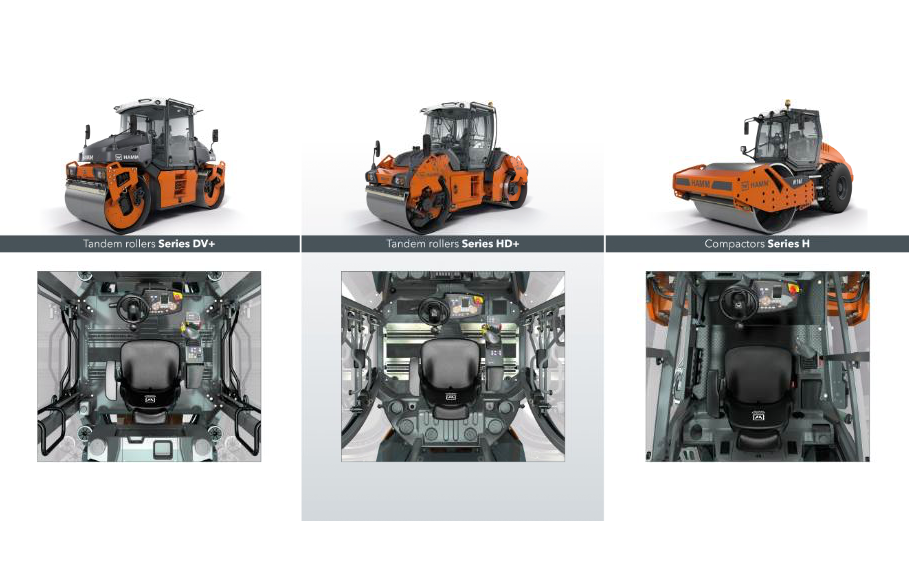

The Easy Drive operating concept is available from Hamm.

At CONEXPO-CON/AGG 2017, Hamm, a Wirtgen Group company, Antioch, Tennessee, showcased new asphalt and soil compactors to boost contractor productivity via unique product innovations and intelligent operation. A highlight for asphalt construction is the DV+ series of pivot-steered tandem rollers, which feature the new Easy Drive operating concept.

The DV+ series tandem asphalt rollers feature vibration with split drum and exclusive Hamm Oscillation compaction. The DV+ series is available in three models: with double vibration (VV), with one vibration and one oscillation drum (VO), and as a combi roller (VT). All models are available in a ROPS version or with a fully tinted panoramic cab. With both versions, the driver has a view of the drum edges, the edge pressing and cutting equipment, as well as the construction site. Viewing panes in the cab floor ensure the driver can always see the rollers or wheels. The Easy Drive operating concept provides top-class ergonomics and comfort in the cab, according to the manufacturer.

- Tier 4 engines with high-efficiency diesel particulate filters

- Large water and diesel tanks

- DV+ operates with split vibration drums are standard

- Pivot steering with large turning angles in four different steering modes

- Easy Drive operating concept

For more information, contact Brodie Hutchins at (615) 501-8105 or Brodie.hutchins@wirtgen-group.com.

Roadtec

The MTV-1100e features a frame fabricated, welded and assembled by Roadtec using American steel. The machines are built by American workers in Chattanooga, Tennessee.

The Roadtec MTV-1100e from Roadtec, an Astec Industries company, Chattanooga, was introduced at CONEXPO 2017 and offers a low, machine-height profile. The 9-foot, 10.5-inch machine height with a deck height of 6-foot, 2-inches is designed to provide the machine operator with a clearer view of the surroundings and the ability to more easily communicate with ground crew. A dual staircase with handrails flanks the machine, allowing workers to cross the paving train without risk of being on the ground between machines.

The MTC-1100e is 47,890 pounds and powered by a 250-hp Cummins QSB 6.7 Tier 4 Final engine. It features a dump hopper with 22-inch triple-pitch segmented auger for mild re-blending before material moves toward the paver, and offers a 500-tph capacity. Sized for mass discharge from standard haul trucks, the front hopper is designed to allow trucks to unload quickly. A vibrating bottom plate in the hopper is designed to prevent material build-up. Heavy duty, swiveling support casters under the hopper are designed to provide smooth movement. The dump hopper is controlled from the main operator platform.

For more information, contact Eric Baker at (423) 265-0600 or ebaker@roadtec.com.

Sakai America

The cabbed version of the 84-inch Sakai SW994 vibratory double-drum roller is designed with operators in extreme climates. However, operators throughout the industry can benefit from a quieter, dust-free environment that an enclosed cab provides.

Sakai America, Adairsville, Georgia, launched a cabbed version of its 84-inch Sakai SW994 vibratory double-drum roller in March. The roller’s comfortable, spacious cab allows operators ample room to move about. The rig’s trim sightlines and wide windows offer the operator excellent visibility. The seat offers five positions to choose from ranging from front facing to plus or minus 45 degrees and plus or minus 90 degrees, depending on working lane. To swivel the seat, operators simply depress the pedal at the lower right side to release the lock while sitting.

The Sakai SW994 with cab has a maximum operating weight of 31,401 pounds (14,090 kg) with load on front axle at 14,528 pounds (6,590 kg) and load on rear axle of 14,903 pounds (6,760 kg).

High-frequency, low-profile vibratory rollers offer low-profile vibration at 4,000 vpm. Operators simply flip a switch to choose frequency and amplitude or no vibration from front or rear drum, independent of each other. A cross-mounted drive and vibration motor help to minimize drum edge marking. The rig is powered by a Cummins QSF3.8 Tier 4 Final engine. Range of speed for the SW994, reverse/forward, is 0-4.5 / 0-6.8 mph (0-7.2 / 0-11 km/h).

For more information, visit www.sakai.com.

Sandvik

Strategically placed dual carbide rings on the new Double TriSpec tool from Sandvik are designed to prevent body wear and maximize carbide tip use.

Sandvik Mining and Rock Technology, Bristol, Virginia, introduced its new Double TriSpec® tool, which is intended for use in extremely abrasive asphalt milling conditions. In road milling, one of the greatest causes of tool failure is known as body wash—the premature wearing away of the steel body that surrounds and supports the vital brazed-carbide insert in each of the tools on the milling drum. When body wash occurs, the tool’s steel body becomes vulnerable to failure, and the tool must be changed before the carbide tip has been fully used—resulting in downtime, lost production and higher labor costs.

The Double TriSpec tool features an additional carbide ring strategically located at the shoulder of the tool to prevent body wash and extend the life of the tool’s steel body. The manufacturer states there is no compromise on cutting speed, and the design allows for maximum use of the carbide tip, which in turn allows even wear in proportion to the tools located across the drum. The new dual carbide ring design maintains puller groove performance throughout the life of the tool for easy removal, as it reduces wear on the washer and block, according to the manufacturer. Sandvik states the Double TriSpec tools will fit any milling machine.

For more information, contact (800) 868-6657 or constr.tools@sandvik.com.

Talbert

Talbert Manufacturing’s new 55-ton extendible trailer, the 55SA-TELE, can be retracted from 53 feet to 32 feet, 6 inches.

In April, Talbert Manufacturing of Rensselaer, Indiana, introduced its 55SA-TELE heavy haul trailer. The deck length of the unit is 54 feet when open, which allows users to haul a wide range of large equipment, plus generators, air compressors, tanks, etc. Operators can then retract the trailer to 32 feet, 6 inches to shorten the overall trailer length to 53 feet, which the manufacturer states eliminates the need for permits.

“Our customers needed a way to minimize costs to remain competitive when transporting the ever longer loads, and the retractable deck helps them do that,” Troy Geisler, vice president of sales and marketing, said.

Talbert designed the 55SA-TELE with a 90-inch swing radius that can be extended to 114 inches with the use of a gooseneck extension. The unit features a 29-foot wood deck in the front and a 3-foot Apitong platform in the rear with beams stretching between. The trailer expands and locks in 4-foot increments.

The 55SA-TELE features one of the lowest deck heights in the industry—20 inches, which optimizes headspace for taller equipment.

For more information, ask about ENitro at sales@talbertmfg.com.

Titan

The PowrLiner 3500 from Titan™ hit the market in May with only two wear parts to minimize maintenance.

Titan™ of Minneapolis expanded its PowrLiner™ series of line stripers in May with the introduction of the PowrLiner 3500 featuring PermaStroke Technology™ with no piston, packings or clutch. The striper is backed by Titan’s lifetime WearGuard® Elite™ fluid pump warranty. The PermaStroke Technology is engineered to deliver consistent pressure from 300 to 3,300 PSI. Maintenance is minimal with only two wear parts—the inlet and outlet valves. The PowrLiner 3500 also simplifies the cleaning process by holding less paint in its system.

It features a FlatLine Pulsation Dampener to eliminate fluctuations and deadband in the system. In addition, the Sureflo™ pusher valve is designed to guarantee the sprayer primes every time it’s started.

It is powered by a Honda® engine. It comes standard with a Titan RX-80 gun, TR line striping tip and 50-foot hose. The cart is built with a swing-back design and two tip holders.

For more information, visit www.titantool.com.

Vogele

The front-mounted Vogele VF 500 extending screed features high stability for maximum evenness, according to the manufacturer.

The new Super 1700 3i and Super 1700-3i and Super 1703-3i from Vogele, a Wirtgen Group company, Antioch, Tennessee, are 8-foot pavers that combine the paver and screed in a single system with the front-mounted VF 500 extending screed. With the ErgoPlus 3 screed console, the screed can be adjusted for infinite variability in a range from 8 feet to 15 feet, 6 inches; or with bolt-on extensions to 19 feet, 6 inches. The entire material handling system of the Super 1700-31 and Super 1703-3i is designed for high output, starting with a receiving hopper with a capacity of 14.3 tons. The high-powered, separate hydraulic drives on the conveyor and auger support laydown rates of up to 770 tons per hour.

- Liquid-cooled, 4-cylinder Cummins diesel engine

- Engine output of 173 hp at 2,000 rpm

- Hardtop with extendable sunshade and comfort seats that swing out

For more information, contact Brodie Hutchins at (615) 501-8105 or Brodie.hutchins@wirtgen-group.com.

XL Specialized Trailers

XL Specialized Trailers has introduced the XL 80 Power Tail trailer in 48- or 53-foot lengths for transporting medium-duty construction equipment. The trailer features a hydraulic fold-under flip tail ramp and a load angle of 10 degrees.

The XL Power Tail is rated at 80,000 pounds overall and 50,000 pounds concentrated in 10 feet. The tail has a lifting capacity of 25,000 pounds for loads centered on the main platform. The tail is comprised of two sections—an 8-foot, 8-inch platform ramp and a 60-inch flip tail.

Standard features include:

- lug-style hinges

- hydraulic pop-up ramp connecting the deck to the gooseneck

- a foot hole and grab handle on each side of the gooseneck

- an 18,000-pound hydraulic winch with a two-function wireless remote and an air kick-out for hauling inoperable equipment

For more information, contact Erin Pilcher at (319) 361-3803 or visit www.xlspecializedtrailer.com.