Meeker’s Warm Mix Systems

BY AsphaltPro Staff

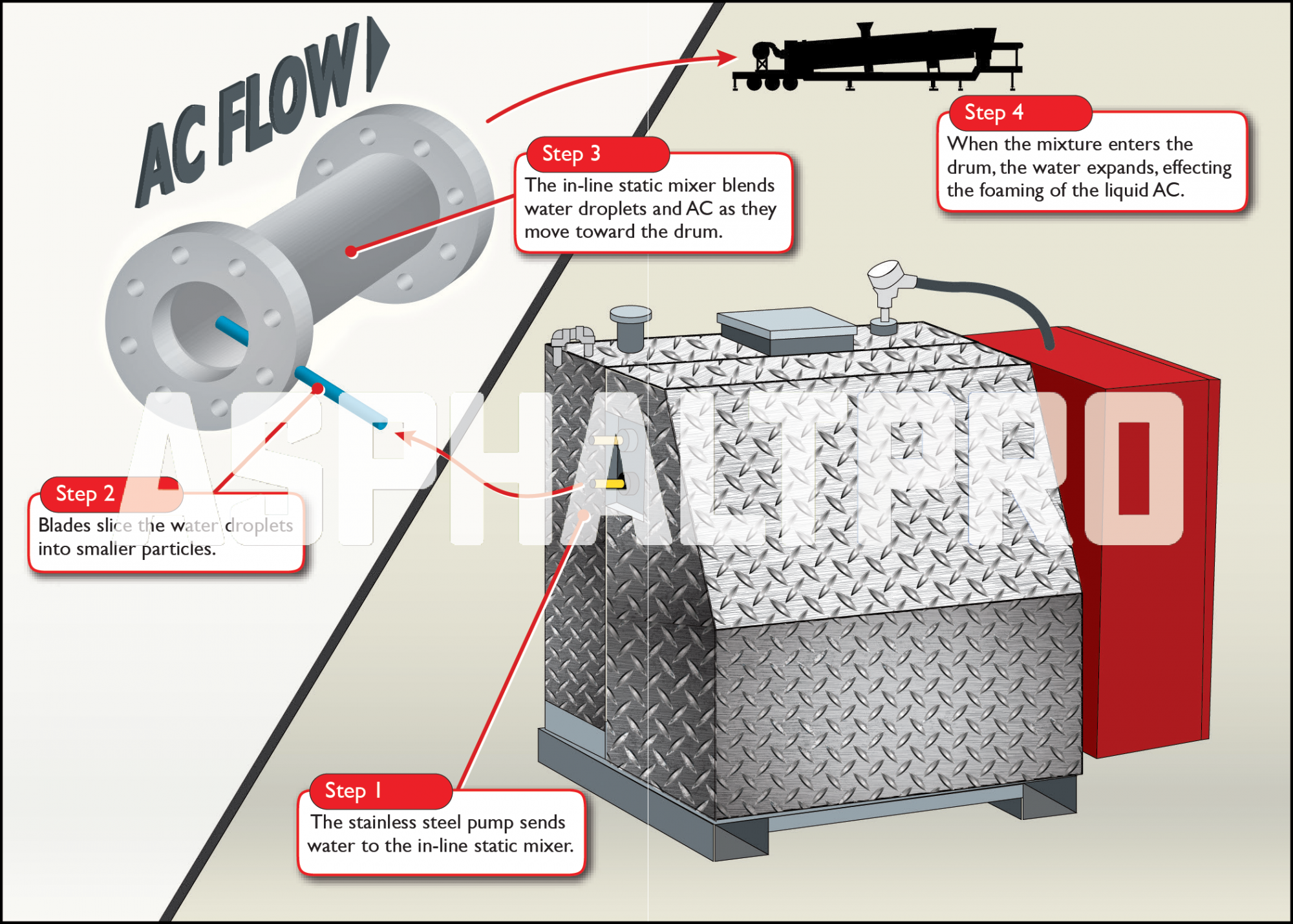

Warm-mix asphalt (WMA) production shouldn’t be limited to drum plants. With that truth in mind, the team at Meeker Equipment, Belleville, Pa., created its warm mix systems for use on either drum or batch plants. Here’s how the drum system works.

A high-pressure, stainless steel pump, driven by a 3- or 5-horsepower variable frequency drive motor sends water from the 63-gallon, stainless steel water tank through a Y strainer and inlet water filter to the in-line static mixer. The system uses the in-line static mixer to blend the water droplets and liquid asphalt cement (AC) together under pressure in the line, forcing them through a set of sharp mixing blades that literally cut and slice the water droplets into small particles. The system pumps the mixture to the drum. When the AC/water mixture releases into the drum, the water expands, creating the foaming of the liquid AC.

At the end of the shift, the operator can press a single button on the unit to have compressed air push out all water in the supply and return lines to ensure no lines will freeze overnight, according to the manufacturer. The worker can also set the system’s space heater thermostat to keep all components within the single-skid assembly at a consistent temperature, which assists those producers running warm-mix in the early spring or late fall months from frozen pipes, etc.

The batch-plant WMA system works in conjunction with an asphalt injection pump. Liquid AC is weighed in an asphalt bucket, as normal. An injection pump sucks the AC from the bucket and pushes it toward the mixer. On its way to the mixer, it is met with water, which the system adds to the pipeline through the Meeker Warm Mix injector. The water and AC mix under pressure and the mixture gets pumped into the mixer, creating the warm-mix foaming action.

For more information, contact Jeff Meeker at (717) 667-6000 or visit www.meekerequipment.com.