Lonesome Prairie Sand & Gravel Solves Too Much Sand

BY Haver & Boecker

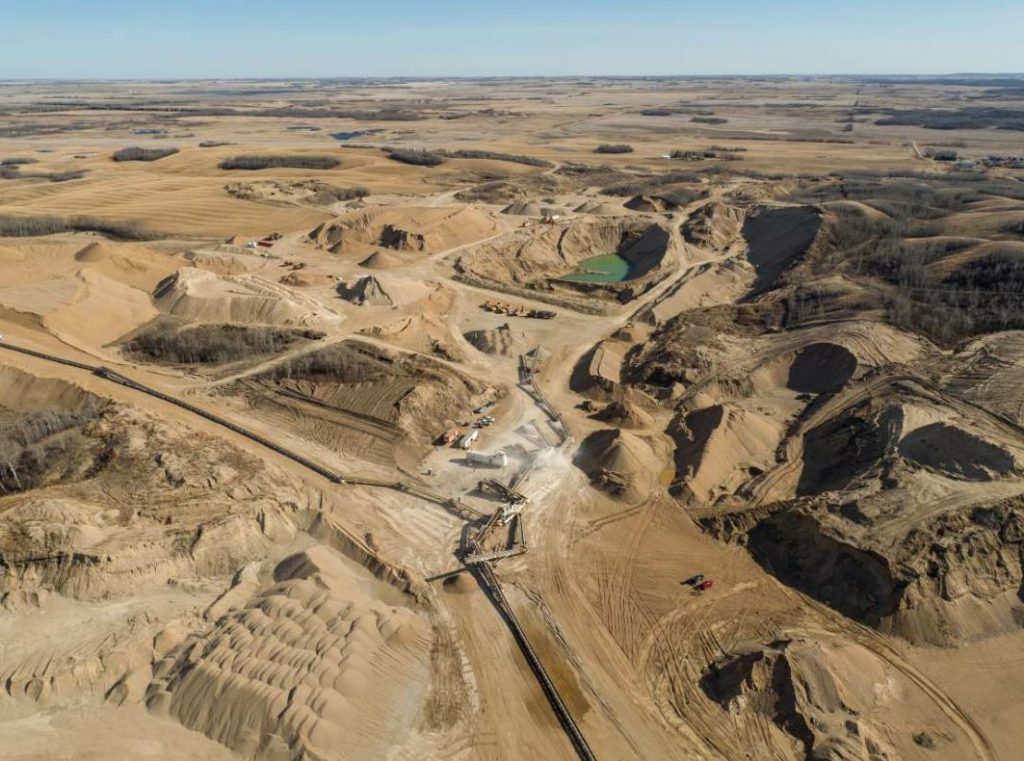

Owners at Lonesome Prairie Sand & Gravel of Canada recognized they had profits buried in millions of tons of sand. The 35-year-old aggregates company found the mountains of sand at its Big Boy Quarry in Wakaw, Saskatchewan—one of five pits it owns—especially troublesome. The quarry is far deeper than most pits—dropping more than 100 feet deep where the average quarry in the region drop 10 to 30 feet. Profits are a challenge because the crews sift through more than a million tons of material every year with only about 200,000 to 300,000 tons of sellable aggregates for concrete and asphalt. The quarry is also located far from large sand-buying markets, thus they are only able to sell about 50,000 tons of sand per year.

Too Much Sand

Haver & Boecker’s F-Class vibrating screen features four-bearing technology, which minimizes structural vibrations and delivers a consistent stroke, virtually eliminating surging, blinding, pegging and material contamination.

The site is in western Canada, where gravel is becoming harder to find. This means most aggregates operations must use portable equipment to move quickly to the next job. A single Lonesome Prairie crew could operate in as many as 15 to 20 pits per year, spending anywhere from two weeks to two months in a single spot.

Lonesome Prairie had been using two portable vibrating screens in the Wakaw location, but the equipment wasn’t holding up to conditions, causing decreased productivity. The existing machines regularly bogged down, leading to sand going through the crushers and contaminating the sellable material, resulting in wasted product and lost profit. To maximize yields, the operation used screen media with opening sizes as large as 7, 8 and 9 millimeters, and then overloaded the screens with as much as 5,000 tons of material a day. The larger opening sizes meant smaller rock—about 5 to 8 percent of the sellable rock—was falling through with the sand that the operation considers waste material. The issue cost Lonesome Prairie about $200 an hour in production losses.

The larger openings were a quick fix for the material surges as well as blinding problems exacerbated by weather. Regular rain, frost and snow dampen the sand, contributing to material clumping together and blinding screen media.

Production rates and lost revenue were only compounded by increased maintenance costs. The sand caused the vibrating screens to wear quickly and require nearly continuous replacement of screen media. Crews needed to change screen media every two weeks, resulting in two to three hours of downtime and 1,000 to 1,500 tons of lost production for each change-out.

“The many issues were frustrating for our crew and our customers,” said Henry Derksen, Lonesome Prairie Sand & Gravel operations manager.

“Contamination meant our material wasn’t as clean as it should be and we were concerned the issues would drive away our buyers. Production amounts were also not as high as we wanted them to be. We were tired of throwing away rock, so we began looking for a solution.”

You’ve Got to Move it

Big Boy quarry is one of five quarries Lonesome Prairie owns. The 100-foot-deep pit sharply contrasts others in the region that average 10- to 30-foot depths.

Lonesome Prairie management approached Hikon Industries, an equipment manufacturer and supplier they work with regularly. They talked to several manufacturers, including Haver & Boecker, a company they worked with in the past. They selected the company’s Tyler F-Class vibrating screen, which features a double-eccentric shaft design, supported by four double-spherical roller bearings.

Hikon and Haver & Boecker agreed to work together and started to design a Tyler F-Class portable plant. Hikon custom-built the chassis around the 6- by 20-foot, three-deck F-Class. Haver & Boecker engineers factored in the desired tonnage and the material that Lonesome Prairie processes to determine what the machine’s stroke should be, the speed and general mounting guidelines. Hikon took feedback from the aggregates company, including adding a specially sized jaw crusher on the chassis. Lonesome Prairie also asked that the bottom deck of the vibrating screen be end-tensioned. In the company’s operation, the design results in longer lasting screen media and 30 percent more productivity than side-tensioned machines.

The finished system was inclined to allow for a high production capacity. The machine included a hydraulic system to lift and position the vibrating screen at the optimal angle. The F-Class uses a base frame that attaches to the chassis. Crews use the hydraulic system to set up the portable vibrating screen in less than 30 minutes, with the entire plant—including conveyors and other peripheral equipment—taking about half a day.

The F-Class portable plant arrived at Big Boy Quarry in April 2016, and Lonesome Prairie began testing immediately. They found the single vibrating screen increased aggregates production by about 25 percent, even as rain came and went. The improved screening action allowed the operation to maintain needed production rates while using screen media with an open area of about 4 millimeters, preventing waste of the smaller sellable material the company had lost while using larger open area screens.

“Price can be a problem in western Canada because our competitive market often calls for cheaper equipment that fit the budget. But despite the higher price tag, I have no doubts we’re improving profits with this machine,” Derksen said.

Screen media change-outs went from every two weeks to every six weeks—saving the operation $10,000 a month. Replacement times on the end-tensioned bottom deck, which requires the most change-outs, dropped to half an hour. Replacement times for the top two decks stayed about the same. Derksen said Haver & Boecker technicians helped choose the best screen media combination for his application, which has helped improve wear-life and reduce contamination.

The F-Class portable plant will stay at Big Boy for some time unless they encounter similar sand and productivity problems elsewhere. Looking ahead, given the success Derksen has seen, he anticipates a fast ROI.