Iowa Builds Perpetual Asphalt Pavements

BY Darwin Larson and Bill Rosener

“Two roads diverged in a wood and I, I took the one less traveled by, and that has made all the difference.”—Robert Frost

Humans are creatures of habit. However, some intrepid municipal engineers in Iowa have chosen to take the road less traveled and have started constructing their new streets with full-depth asphalt. They have found that it is making a significant difference in the overall pavement condition index (PCI) of their streets.

Iowa cities have a long history of paving new roadways with Portland concrete cement (PCC) and then using hot-mix asphalt (HMA) as a rehabilitation tool.

That approach is changing as more cities across the state of Iowa embrace the use of full-depth HMA streets. These engineers are constructing, or reconstructing, their streets with a perpetual asphalt pavement design.

Perpetual Pavement is an asphalt pavement designed and constructed to last in perpetuity without requiring structural rehabilitation or reconstruction, and needing only periodic surface renewal to address distresses confined to the top layer of the pavement. The construction of perpetual asphalt streets is fast, economical, and provides a higher ride quality than PCC over the life of the roadway.

Design a Perpetual Pavement

A Perpetual Pavement takes best practices as well as a good design.

The design and construction of a Perpetual Pavement is similar to thick, full-depth HMA pavements, with two distinct differences.

First, the Perpetual Pavement is designed thick enough to withstand 100 microstrains at its base layer. This insures that the pavement will not fail due to bottom-up cracking and that the traffic distresses will remain in the surface layer of the pavement. The surface course can be rehabilitated periodically with a simple mill and overlay to provide a smooth, safe driving surface for the traveling public.

The second difference is that the asphalt base course is designed with lower air voids, and higher binder content, than the thick HMA pavement to provide a rich, flexible asphalt base. This base course provides extra flexibility to withstand heavy traffic loadings. If these two characteristics are met, the Perpetual Pavement can provide an unlimited life span.

As with any pavement design, a strong drainable base and subgrade is needed for optimum performance. Many of the soils in Iowa do not provide a strong enough foundation for long pavement life. A subgrade with a California Bearing Ratio (CBR) of 5 is recommended as the minimum necessary for a pavement to be considered perpetual. Since most of the soils in Iowa do not meet this requirement, the use of a chemically stabilized base or a modified subbase under the pavement may be needed. The use of subdrains on all new construction or major rehabilitation is encouraged to keep moisture away from the pavement’s foundation. As mentioned above, the asphalt base layer needs to be flexible and asphalt-rich to prevent fatigue cracking and infiltration of water. This is accomplished by designing the mix with a target of 3 percent voids.

The intermediate asphalt layer(s) need to be strong and durable. The mix should feature stone-on-stone contact and a PG binder that will provide low temperature cracking resistance.

The surface course should be designed to provide a rut-resistant, durable wearing surface. A polymerized asphalt binder may be needed depending on the traffic loading and traffic signalization.

Take Advantage of Life Cycle

A PCI of 60 to 80 is generally considered “good.” The Iowa Department of Transportation (IDOT) uses a PCI of 60 as the trigger for when rehabilitation of a roadway needs to be considered. Although cities would like to maintain their roadway network in a “good” condition, funding issues typically prevent this.

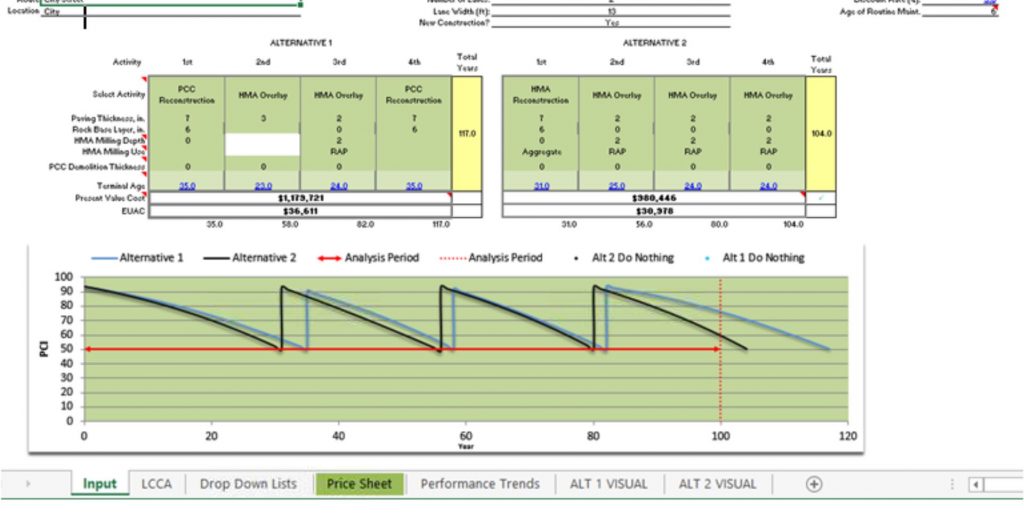

Most cities try to address their roadways when they reach “fair” condition, which is represented by a PCI between 40 and 60. For comparison of a PCC roadway and a perpetual asphalt pavement, the I-SAVE Life Cycle Cost Analysis program developed by Iowa State University Professor Dr. Ashley Buss was used.

The I-SAVE program uses historical IDOT highway pavement performance data to develop future performance curves for pavement construction and rehabilitation activities. The analysis shown in Figure 1 uses a 100-year analysis period and a PCI of 50 as the point at which rehabilitation or reconstruction would need to occur. IDOT performance curves for new PCC pavement show the first rehabilitation would be required at 35 years at a PCI of 50. Similarly, a new HMA pavement would require its first rehabilitation at year 31 if it was allowed to reach the same level. Over the 100-year period, two asphalt overlays of the PCC and a reconstruction at year 82 would be necessary. For the perpetual HMA pavement, three mill and fill resurfacings would be necessary over the same 100 years. The total construction cost for the PCC alternative in today’s dollars would be slightly over $1.3 million versus $1.13 million for the Perpetual Pavement.

The I-SAVE program shows that the present value costs of the maintenance and rehabilitation of the perpetual asphalt pavement would be approximately $60,000 less than the PCC pavement over identical 100-year periods. This total, added to the savings of $170,000 for the initial construction, brings the total project savings to $230,000 in today’s dollars for the city. In addition to the 19 percent savings, the overall pavement condition and quality of ride to the taxpayers will be higher with the perpetual asphalt pavement.

The cost of a street reconstruction is typically five to six times more than the cost of pavement rehabilitation. Perpetual Pavement eliminates the need for costly reconstructions and the negative impact that it has on businesses and home owners. Asphalt is fast to construct initially and is easily rehabilitated with a simple 2- to 3-inch mill and replacement of the surface wearing course. The milled asphalt is recycled into the new surface course and provides future value to the owner. The surface rehabilitation can be done at night, or on weekends, to limit the inconvenience to the traveling public. An important benefit of a Perpetual Pavement is that the mill and fill resurfacing never results in a loss of curb exposure and the resulting drainage issues associated with overlaying a PCC street with asphalt. In addition, if the sidewalk curb ramps meet current Americans with Disability Act (ADA) standards, they will not have to be reconstructed as part of a mill and fill operation. Asphalt is resistant to winter brine and salt. These benefits result in significant long-term cost savings for the city.

Iowa Cities Using Perpetual Pavement

A full-depth Perpetual Pavement must be thick enough to withstand 100 microstrains at its base layer. The intermediate asphalt layer(s) mix needs to be strong and durable, featuring stone-on-stone contact and a PG binder that will provide low temperature cracking resistance. The surface course should be designed to provide a rut-resistant, durable wearing surface, possibly requiring a polymerized asphalt binder, depending on the traffic loading and traffic signalization.

City of Waterloo

The City of Waterloo has been building full-depth asphalt pavements since 1984. Their streets have benefited from a local option sales tax (LOST) that was approved by residents in 1992 and has been reapproved by voters at a 70 percent approval rate five times since its adoption.

“People know where the money is going and they believe in it,” Waterloo City Engineer Jamie Knutson said. “It brings in approximately $8.5-9 million a year depending on the economy and it all goes towards roads and infrastructure improvements. It is a Godsend. I’m frightened to think about how bad our streets would be if we didn’t have that money coming in. The town would suffer, the condition of our roads would suffer, and it would directly impact the economic development of this city.”

The fact that Waterloo has been building full-depth asphalt streets for over three decades makes them unique, but what really sets this city apart is that they have also been using alternate pavement type bidding for nearly 30 years.

“I love the competition it brings to our city projects,” Knutson said. “I always feel we get the best value for our taxpayers.”

The results of the alternate bidding went back and forth during the 1990s, but for the past 20 years, the city paving project has gone asphalt. The results of these programs are a case study on how asphalt can perform in a municipal setting in Iowa.

“Since the projects have started going asphalt consistently, we have not had to rehabilitate a single asphalt street. We have crack filled and done some light maintenance, but 20+ years in, they are performing great,” Knutson said. “Last year, we milled off 2 inches and overlaid a full-depth street we had constructed in 1988. We did some curb and gutter repair and ADA ramp repairs at the same time. The street looks brand new and it is 30 years old. We will probably have to mill it off again in another 30 years or so and at that time we will probably have to replace all the concrete curb and driveways, but we will still have all the paving intact. We are truly building Perpetual Pavements.”

City of Dubuque

Figure 1. I-SAVE Program

The City of Dubuque has a history of using full-depth asphalt in the past, but has recently increased the number and frequency of HMA streets.

“We use both pavement types,” said Jon Dienst, civil engineer II for the City of Dubuque. “It depends on the needs of the project and the application that best suits—asphalt or concrete. For example, the 17th St. Reconstruction and the 22nd St. Reconstruction are both on very steep grades. By utilizing asphalt, we are capitalizing on the black asphalt melting the snow and ice faster to give our residents a safer street to drive on in the winter. Our Public Works department was lobbying for asphalt on these projects because they are capable of doing their own maintenance on the street. We have our own paver and could even do a mill and fill of the surface with our own forces in the future.”

When asked about the performance of the city’s existing asphalt streets, Dienst added, “We have a project on W. Locust Street that is over 20 years old and the only maintenance we have done to date is crack seal the street. It is performing extremely well.” Dienst went on to say, “On our new projects, we are building Perpetual Pavements. In the past, we might not have put as much effort into getting the subgrade prepared properly. Not anymore. We are building up the subbase with strong aggregate sections and using subdrains to drain the water away. The construction of these projects has been very successful. We have a good working relationship with our paving contractor and we have partnered together very well to build these streets.”

City of Des Moines

“It’s all about the speed,” said Dave Kamp, chief design engineer for the City of Des Moines. “Asphalt is fast to construction initially, and it is fast to maintain and to rehabilitate in the future. The quicker the construction occurs, specifically reducing the time residents cannot access their driveway, [the] less impact to the residents and business along a construction project.”

Des Moines has been shifting toward full-depth asphalt construction over the past five years with an impressive list of streets that have been completed including: Polk Boulevard, 42nd Street, 31st Street, McKinley Avenue, E. Court Avenue, and in 2019, the reconstruction of Fleur Drive. According to Kamp, asphalt had a poor image in the past due to its use in covering up failing PCC or being under-designed due to budget constraints.

“It has taken a while to build up an impressive list of full-depth asphalt projects from the past that have performed exceptionally well. We don’t get asked much anymore on why we chose asphalt for a project, but when we do, we can point to a long history of successes.”

The Fleur Drive reconstruction project has been a long time coming and the need to reconstruct the project in a timely fashion weighed heavily in the decision to make asphalt the pavement of choice. “The decision first came down to speed. Second, the physical constraints of the project were not conducive to bringing in a concrete paver. Third, all the intersection tie-ins were going to be asphalt so there was an aesthetic consideration. And finally, we designed this street as a

Perpetual Pavement. When it needs to be rehabilitated in 20-some years, we can mill off the top 2 inches and replace it, and have a brand new street with limited impacts to our citizens.”

State of the Practice

The use of Perpetual Asphalt Pavement continues to grow exponentially across the state of Iowa. In 2019, the cities of Des Moines, Council Bluffs, Dubuque, Clear Lake, Waterloo, Davenport, Cedar Rapids, Fort Dodge, Bettendorf, Clinton and Ames, and many other smaller communities will all construct full-depth asphalt streets. Some of these will be fully designed Perpetual Pavements. Some of them will be strong, traditionally-designed asphalt pavements.

The assets that quality-constructed asphalt pavements bring to the table are undeniable. Asphalt is resistant to damage from salt and brine. It is 100 percent recyclable. It is fast to construct and easy to maintain. The cost benefit to municipalities over the life of the pavement makes asphalt the clear choice for Iowa’s cities.

Reprinted with permission from the Spring 2019 Iowa Asphalt Report. For more information on building a Perpetual Pavement, please contact the Asphalt Paving Association of Iowa at (515) 233-0015 or visit the Asphalt Pavement Alliance here.

Darwin Larson, P.E., is the APAI municipal field engineer. He worked for the City of Des Moines in various departments for 36 years. He received his Bachelor of Science degree in Civil Engineering from the University of Minnesota in 1976 and became a registered professional engineer in 1980.

Bill Rosener is the executive director of APAI. You can learn about his goals in this role here.