International Tree Mix

BY Sandy Lender

As part of its The Road Forward climate stewardship mission toward net zero carbon emissions, the National Asphalt Pavement Association (NAPA) listed industry goal number three would involve developing a net zero materials supply chain by 2050. This puts an emphasis on Upstream Scope 3 Emissions such as those created or emitted by vendors who supply our liquid asphalt binder or asphalt binder replacements.

One of the companies offering to replace a portion of liquid binder in asphalt mix designs is Stora Enso, a provider of renewable products in packaging, biomaterials, wooden construction and paper, headquartered in Helsinki. This unlikely source is one of the largest private forest owners in the world and has found a way to use lignin—one of the main building blocks of a tree—as a sustainable alternative to partially replace liquid bitumen in asphalt mixes. The company explained that its Lineo® product can be used to construct “climate-improved roads that have a lower carbon footprint and that store carbon.”

Let’s take a look at this concept starting with a breakdown of what lignin is and how Stora Enso produces Lineo from it and then discussing how Lineo is working in asphalt mixes for Peab Asfalt in Sweden.

The Solution for Blue Smoke Emissions in Europe’s Green Capital 2021

Bioenergy Binder

“Lignin is an organic polymer that comes from wood,” the company shared. “It is the second most common macromolecule in nature. It binds the fibers of a tree together. It is extracted in the pulp-making process.” Traditionally, lignin is used in energy production or to make bio-based products, and Stora Enso does this without increasing the number of trees it harvests. “The trees that are used to make Lineo come from sustainably managed, traceable forests with FSC®/PEFC™ chain-of-custody and ISO 14004 certifications.”

The company produces lignin industrially at its Sunila Mill in Finland, producing around 50,000 tonnes per year. This makes Stora Enso the largest kraft lignin producer in the world, according to the manufacturer.

Heikki Lotti, the business development manager for binders at Stora Enso, shared with AsphaltPro that the company provides the full input data for compiling Lineo’s environmental product declaration (EPD) according to EN 15804 +A2:2019. The full lifecycle inventory data is available for the product and is based on its continuously operating production of lignin.

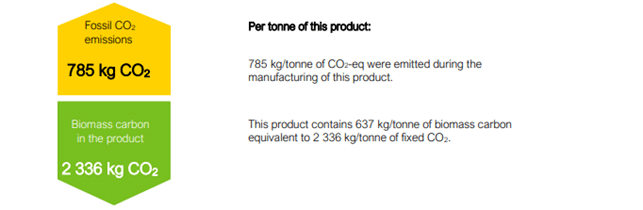

“From this third-party verified EPD input data, an EPD for any end-product can be compiled showing the positive impact of replacing the fossil-based components in the end-product,” Lotti shared. “By doing so, users of Lineo can obtain and register a validated EPD for their end-product. In the recent site-specific calculation, a 15 wt% replacement of the virgin fossil-based bitumen with Lineo kraft lignin results in carbon neutral cradle-to-gate asphalt.” (See Figure 1.)

Test It Out

At this time, the 15% by weight of binder replacement level represents more than what early field tests are using, but also represents a figure Stora Enso is preparing to meet and exceed production-wise.

“Lineo kraft lignin usage as bitumen replacement is taking its early steps and the demand is increasing, especially in the countries where authorities and companies are putting high emphasis on reaching their climate neutrality objectives,” Lotti shared. “Stora Enso has recently invested heavily in optimizing the logistics chain of Lineo, making lignin even more economically attractive in all destinations globally.”

In 2020, Peab Asfalt began testing the use of lignin in its ECO-Asfalt surface mixes in Sweden. Johan Bolander, production manager for Peab Asfalt, shared with the Stora Enso audience: “We see this as a very exciting development, using raw materials from the forest to reduce our CO2 emissions and at the same time make ourselves less dependent on imports. If we can drive the development towards more binders for our paved roads coming from Nordic forests, it is very positive. We see environmental benefits, job creation and more sustainable coatings ahead of us as we now develop the technology of adding lignin to our ECO-Asfalt.”

Figure 1. Emissions Statement

Fossil CO2 emissions and carbon stored in Lineo® kraft lignin

Peab’s laboratory manager, Lars Jansson, also shared excitement with the Stora Enso audience. “We have been working with different types of lignin for a few years now and it is important that we trial it in real production. Last year [2020], we performed our first test surfaces with lignin and now we are moving forward with developing the concept. It feels very exciting and important to have this cross-industry collaboration and to work closely with our customers to develop a climate-approved and more durable asphalt pavement. We are pleased that we can put these test stretches in place and contribute to municipalities meeting their environmental goals.”

In 2021, Peab placed a test section along with the Swedish road and infrastructure operator Svevia. A recent test is being conducted on Bråtvägen road in Forshaga municipality where the amount of lignin used in the binder is 10%. In addition to lignin, Peab has included 30% re-used asphalt from milled road surfaces.

During the testing period, the roads have been subjected to tough winter conditions, spiked tires and snow ploughs, showing the roads with Lineo-based asphalt are durable.

“Regarding the test results with Peab and Svevia, the paving projects done by our partners in the past with Lineo lignin containing asphalt, have all proven to work well,” Lotti shared. “Although, more time is needed to demonstrate the full performance of the road. Our confidentiality obligations limit Stora Enso from sharing any specific measured parameters collected during the tests. The paving works communicated in the public domain by Peab Asphalt have performed well and have stayed free from any failures, despite the harsh winters and very hot summers we have behind us in the Nordics. The most recent reference from the UK, communicated by SteelPhalt, a Harsco Environmental Company, will collect further evidence from the UK conditions.”

Lotti stated the objective of replacing a portion of the virgin bitumen with Lineo is to improve the carbon footprint of the asphalt blend without compromising on the technical performance, and they are seeing that objective met.

“Currently, the lignin-containing asphalt shows equal properties compared to standard PEN-grade bitumen-containing blends,” Lotti shared. “There are some indications showing improved stability, rutting-resistance and improved water resistance. The objective is, however, to be on par when it comes to the technical performance when replacing virgin bitumen with Lineo kraft lignin.

“It is considered that the potential improvement of technical performance merits further study. Especially the performance with polymer-modified bitumen-containing blends.”

As noted above, Peab mixed in reclaimed asphalt pavement (RAP) on a project as well.

“Kraft lignin, like Lineo by Stora Enso, contains various components with antioxidant and rejuvenating properties,” Lotti shared. “The study of the impact of these properties on recycled asphalt pavement (RAP) and the recycled bitumen behavior is at a very early stage. There is still limited historical data available to validate any such impacts on the milled road surfaces or the recycled bitumen content.”

The Peab asphalt plant uses renewable fuel (bio-oil) for drying and heating the stone material and Lotti told AsphaltPro the Lineo product can support reduced hot-mix asphalt (HMA) production temperatures.

“Lineo kraft lignin does not require high temperatures to melt or to activate its binder properties,” Lotti shared. “This allows the plant operator to reduce the blend temperature if required. The use of lignin also supports the current trend of reducing blend temperatures and shifting towards WMAs, thus contributing to lower plant energy consumption and carbon emissions.”