International Recycling Locations

BY Max Glaskin

Making new roads from old asphalt saves natural resources. Pinpointing the locations of these reusable materials maximizes the conservation of dwindling aggregate reserves in nations that need good connections to thrive.

For example, The Netherlands is among the best connected in the world with a mesh of transport links. It has 138,600 km of roads, 3,200 km of railways and 6,200 km of waterways that serve not only the needs of the Dutch but also of every country on the continent that receives or exports goods through Rotterdam, Europe’s busiest port.

Maintaining, improving and extending these vital surface transportation networks demands careful use of natural resources. These resources are limited in the Netherlands because it is relatively small at just 42,000 square kilometers. Its only source of aggregate for road building is river gravel and the Dutch government first took steps to protect this dwindling reserve in the 1970s. Since then, the natural resource conservation initiative has developed into the wholesale practice of recycling the asphalt from old roads to provide materials for new ones.

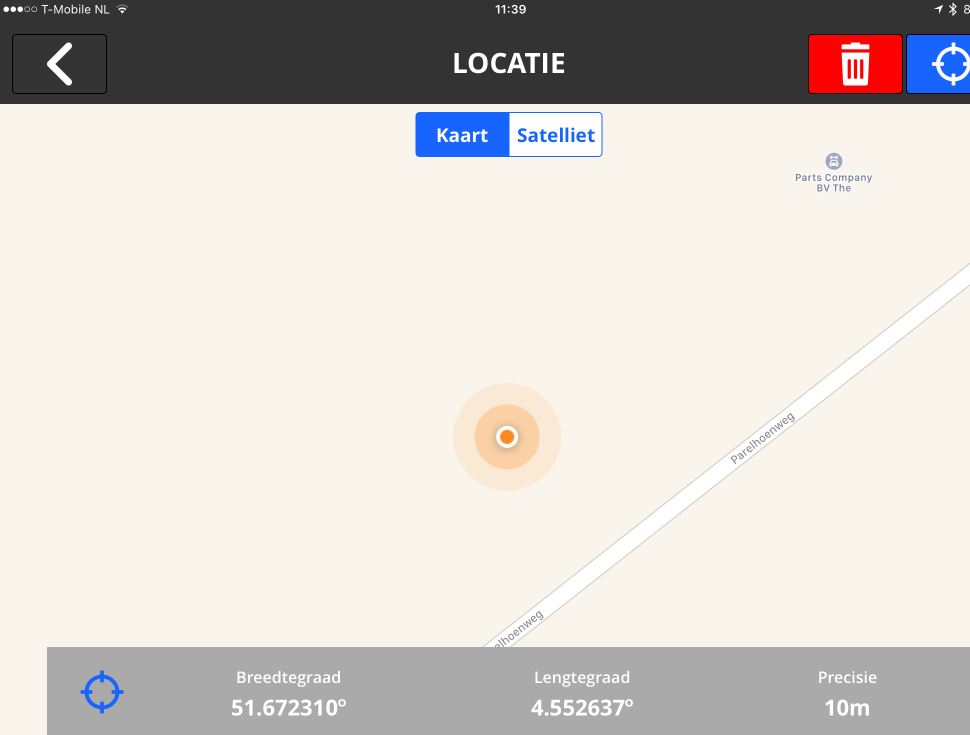

The Gappless app shows the location of asphalt sample to be taken. The R2 unit assists the worker in collecting the core within 20 centimeters of accuracy.

“Today between 50 and 70 percent of the base course for a new piece of road comes from recycled asphalt. That’s a very big saving,” said Armon Jongenelen of Dura Vermeer, a Dutch construction infrastructure and engineering company. “Even for the surface layers of a new road, up to 30 percent of the material originates from the surface layer of an old highway.”

The Trimble R2 GNSS receiver unit is mounted to the coring device.

Some of the old material may actually have been laid down by Dura Vermeer in the twentieth century. The company traces its origins back to 1855 and has grown into a business employing around 2,400 workers, with revenues of more than a billion euros annually. It has been constructing roads for more than half a century so it would have been likely they built some of the old highways that are now ready to be renewed with recycled asphalt.

One of Dura Vermeer’s guiding principles is to be inventive, looking for creative and fitting solutions. As the head of quality in the company’s infrastructure and road construction division, Jongenelen has followed this principle to make sure that only recycled asphalt of an acceptable standard is used in new roads.

In earlier years, road construction was not as carefully controlled as it is today and materials were sometimes used that would not meet modern standards. Before an old road is milled for recycling, small samples must be taken and analyzed in the laboratory to assess the ingredients.

“Of course, we must keep a record of the locations from where each sample is taken so that the results of the laboratory analysis can be plotted back onto a map of the old road,” Jongenelen said. “Then we will have confidence we’re only using materials from the places where samples have been assessed as good and avoiding recycling materials that are contaminated.”

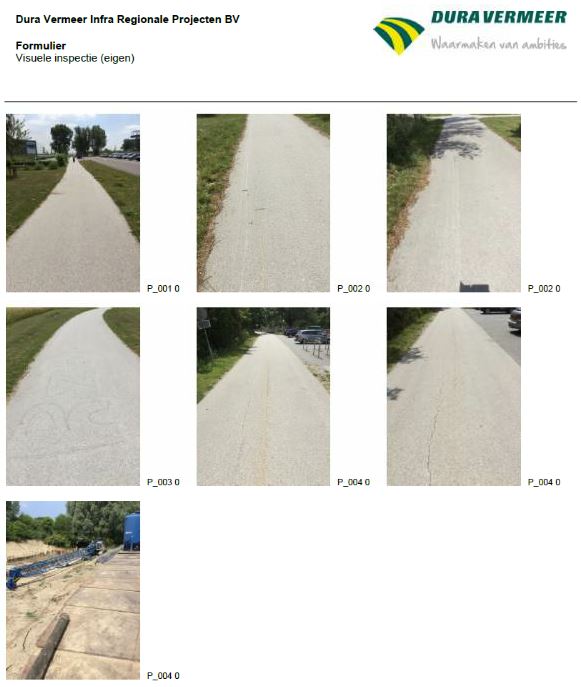

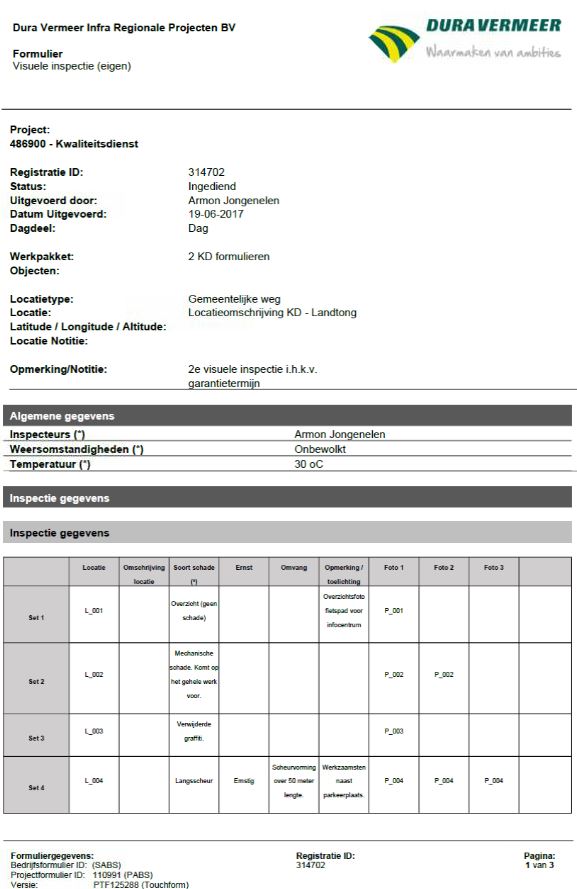

After a road has been completed and opened to traffic, Armon Jongenelen and his colleagues are tasked with checking the quality of the surface so that any damage can be repaired. Dura Vermeer workers use a Trimble R2 GNSS receiver and Gappless app platform on an iPad to record its location, along with information about the state of the road surface.

The key contaminant that must be avoided is tar. This black viscous liquid was used frequently in asphalt and in some countries to seal the surface of roads and parking lots because it produced a smart finish in line with the popular image of “black top.”

Another attraction of using tar as a sealant is that it helped to preserve the asphalt underneath.

However, it is not acceptable to include tar in modern roads in the Netherlands and in many other countries. The use of tar in new roads was banned in the Netherlands in 1991.

“That’s why it’s necessary for us to measure accurately the location of each sample of asphalt that might be recycled,” Jongenelen said. “We have to take one sample for every 500 square meters of an old road asphalt and we had been using a simple consumer-style GPS device to get the location data. It was relatively inexpensive but it was only accurate to within 5 meters.”

After the Dutch government specified that the minimum accuracy of location measurements for tar samples had to be 20 cm, Jongenelen had a decision to make.

“We chose to look for better technology that our staff could use without a problem.”

For a year, he tested a Trimble R2 GNSS receiver in combination with the Gappless app on an iPad, which his team uses for project administration. “The location is captured with one click on the iPad,” Jongenelen said.

The Gappless app shows the location of asphalt sample to be taken. The R2 unit assists the worker in collecting the core within 20 centimeters of accuracy.

“When we are taking a sample of asphalt, the R2 is positioned on top of the drill. The R2 connects with the iPad via Bluetooth. It takes no more than 10 seconds to get a measurement of the required precision,” Jongenelen said. Getting the data from the R2 into a form that is usable for both the user and the database was facilitated by Gappless (see sidebar). Trimble has also supplied an application program interface (API) so that the coordinates in the system required by the Dutch authorities are available in the Gappless portal.

After the 12-month test period, Dura Vermeer invested in seven Trimble R2 GNSS receivers for their quality control engineers across the Netherlands. While the R2 works with various consumer mobile devices, including those with Android or Windows platforms, Dura Vermeer prefers to link each of its R2s with an iPad because it can host the Gappless software. “The iPads come fitted with SIM cards, which get data through the European GSM (Global System for Mobile Communications) signals from SmartNet NL. This gives us the NRTK [Network Real Time Kinematic] positioning that’s needed for our measurements to be precise within 20 centimeters,” Jongenelen said.

Jongenelen is happy with how the R2 receivers have been performing over the 12 months that they’ve been out in the field, recording the locations of each sample of old asphalt before decisions are made about whether it is acceptable for recycling.

To assess the condition of the pavement, Dura Vermeer employees take cores with the R2 unit mounted on the coring machine, recording the locations of each before decisions are made about whether it is acceptable for use as recycling material.

The Trimble R2 and iPad combination has also been pressed into service by Dura Vermeer for two other applications further along in the road construction process.

When a new road is being built, the layer of sand and gravel that is laid beneath it must meet a density standard. This is measured by technicians who use a Troxler nuclear density moisture gauge that assesses the degree of compaction. The R2 and iPad are used to record the location of the density measurement, which has to be done every 2000 square meters of road construction.

After a road has been completed and opened to traffic, Jongenelen and his colleagues are tasked with checking the quality of the surface so that any damage can be repaired before the condition deteriorates further. Again, the R2 and iPad are used together to record its location, along with information about the state of the road surface. For assessing the condition of the asphalt, the Dura Vermeer employees use what is probably their most treasured equipment –their eyes.

Digital Project Management

Location information from the Trimble R2 is fed into Dura Vermeer’s project management system via the Gappless app platform, which uses the Trimble API to manage the GNSS data. “We introduced Gappless to our team in 2015 and now it is used by about 450 of our people who manage our projects and collect data from the field,” Armon Jongenelen said. “It is very easy to set up and easier to use than spreadsheets or paper forms.”

Gappless allows a manager to create a digital form for a task or activity, requesting specific data. The person charged with collecting that data can then access the form on his own iPad when out in the field and then use the touch screen to enter it.

“It means that the manager can see the information that has been recorded in the field,” Jongenelen said.