Indiana Overlays with Aramid Fibers

BY Jason Martin

Approximately half of all infrastructure dollars are invested in pavements with more than half of that investment in overlays of existing pavements, according to the Targeted Overlay Pavement Solutions (TOPS) program from the Federal Highway Administration. One approach to enhancing overlay performance is using aramid fibers. This targeted overlay pavement solution can allow state and local highway agencies to maximize their investment to provide safer roads and to help ensure longer-lasting roadways for the traveling public. Aramid fiber has been proven to enhance properties of the asphalt mix like thermal cracking, block crocking, rutting, fatigue and modulus/structural number without changing the job mix formula, in studies performed at the National Center for Asphalt Testing (NCAT), Blankenship Asphalt Tech and Training (BATT), Oregon State University, and others.

Graph courtesy of Surface Tech

In 2018, the Town of Plainfield, Indiana, collaborated with Milestone Contractors LP, Indianapolis, and Surface Tech LLC, Solana Beach, California, to provide an overlay pavement solution to improve the performance of the overlay with the objective of extending the pavement life. The Town of Plainfield wanted to control cracking on an industrial service road near the Indianapolis airport.

Milestone’s crew milled and placed a 2-inch overlay on June 27-28, 2018, on Stafford Road. The control section consisted of a PG76-22 in the passing lane while the ACE XP aramid fiber section with a PG76-22 was placed in the truck lane.

Initial Overlay Performance

To evaluate the consistency of each mix, plant produced samples of mix with and without fibers were collected from Milestone’s HMA plant on each night of production to check asphalt binder content and aggregate gradation. Asphalt binder content was tested from a sample each night of paving following AASHTO T164 while the recovered aggregates were tested for gradation following AASHTO T30. The results indicated that the asphalt content from the paving production was consistent at 5.35%. The aggregate gradation of the dense-graded mix from the plant produced mixes was also consistent for both nights of paving. One can conclude that the only difference between the two mixes is with and without ACE XP fibers.

Volumetrics alone is not enough to quantify performance differences. Most roads look great when they are paved, but owners want to know how they will perform after the first few years. They want to know if aramid fiber will add to the life of the pavement, delaying maintenance or reconstruction. Just adding one year to a pavement saves valuable construction dollars that can be spent by the owner to improve other pavements in the area.

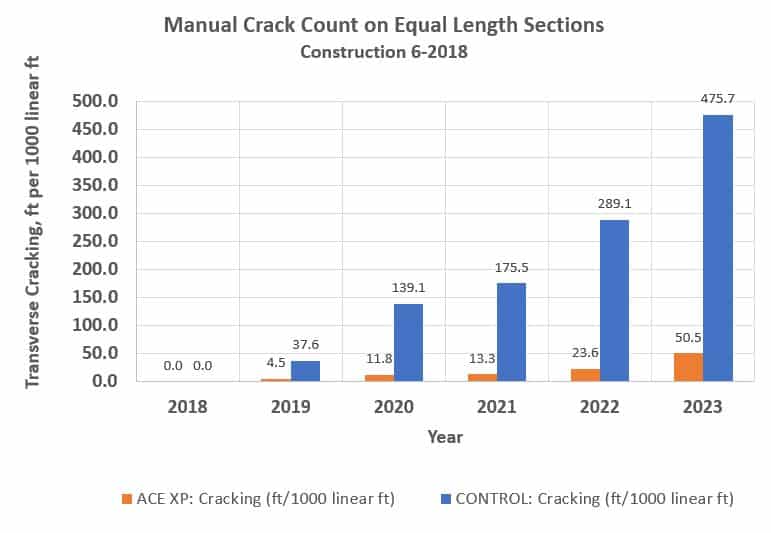

Site Supply conducted a field survey on the project in 2019 after one year of service. The control mix in the passing lane exhibited 124 feet of lineal cracking, which translates to 37.6 feet of cracking per 1,000 lineal feet (normalized to project length). The ACE XP aramid fiber mix exhibited 15 feet of lineal cracking over the project length, which translates to 4.5 feet of cracking per 1,000 lineal feet (normalized to project length).

Surface Tech Announces Adoption of ASTM Standard D8395-23 for Aramid Fibers in Asphalt Mixtures

Long-term Overlay Performance

For the next five years, both pavement sections were surveyed manually by Site Supply and then a detailed site survey was performed in May 2023 by BATT to quantify the long-term performance. The figure below shows the transverse cracking in feet per 1,000 lineal feet from 2018 to 2023. One can see an immediate improvement after the first year of in-service life and that improvement in pavement life follows for the next four years. The ACE XP fiber section has extended the life of the overlay by more than four years. The control section cracking in 2019 is comparable to the ACE XP cracking in 2023. The rate of cracking over five years for the control section is 128.2 feet/1,000 lineal feet per year while the ACE XP section is 10.7 feet/1,000 lineal feet per year.

BATT performed the most recent manual crack count and video Pavement Condition Index (PCI) survey in May 2023. Not only was the transverse cracking impressive, but the PCI also showed an improvement of 5 points after five years of service, where the control was a PCI of 84 and the ACE XP section was 89.

“The reduction in transverse cracking is some of the most outstanding that I have seen,” said Phillip Blankenship, owner of BATT.

The ACE XP section has improved the cracking resistance of the overlay for the Town of Plainfield. Using a targeted overlay solution (an innovative material such as ACE XP), the overlay life has been extended, which will allow the Town of Plainfield to pave more roads in the future.

Recently, ASTM has standardized the use of aramid fibers in asphalt mixes with the adoption of ASTM D8395-23. This standard calls out key properties such as length, density, strength, modulus and decomposition of the fiber. This is to ensure that customers are receiving high performance aramid fiber for their asphalt mixes, which is designed to improve the mix’s resistance to rutting, cracking and fatigue.