How to Train New Operators to Pave

BY John Ball

While working with a company during the 2019 construction season, I needed to show a young man how to set up the screed for the day’s paving. He’d been on the job for about three weeks and had learned a few shortcuts that could cause a poor end product.

When I asked him to hand me the straight edge so we could check the crown of the screed and match height, he got frustrated. He threw his hat down, said “I quit,” and stomped away. This fellow didn’t want to learn to use a straight edge. He didn’t want to “waste time” nulling out the screed and re-setting the tow arms. He didn’t want to unlearn his bad habits and learn the right way to do it.

After a few minutes, he calmed down and came back to the task, but his kind of attitude can be detrimental to an operation. That kind of attitude can be avoided by weeding out the bad apples when hiring and it can be avoided by training the right steps from the first day. His frustration came from not knowing.

If you have long-time paver operators who are set in their ways, maybe they aren’t the right guys to teach the new workers coming in. Or maybe they can be mentors who help alongside your training director and foreman. Either way, you want to teach the basics to the new workers so they understand why you’re asking them to use a straight edge—or any other tool—before they get to start up a machine and pave.

Photos courtesy of John Ball

The first thing you want the new guy to know how to do on the back of the paver is how to null out the screed or set it up. Number One, he’s going to zero out the tow point cylinders or find the halfway point. Number Two, he’s going to go to the depth crank and find neutral to null out the screed. Number Three, he’s going to lift his endgates so they’re level with the end of the screed. Number Four, now he can lift the screed up to check the crown and match height. That means that the screed is balanced.

The second thing you want the new guy to know is to look at the depth crank as if he’s looking at the face of a clock. Think of the top—or north—as 12 o’clock. The far right will be 3 o’clock. The bottom—or south—will be 6 o’clock. The far left will be 9 o’clock. One whole turn around the clock will cause the screed to rise about an eighth of an inch.

This is where Windmill Johnny comes in—we don’t want him making two and three turns at a time. They travel one length of a paver—and then some—before we get a reaction in the mat. In other words, one turn of the depth crank will get a 66 percent reaction in one length of the paver.

The third thing you want the new guy to know is to make sure the endgate and shoe are clean. The shoe is about an inch and a half wide. You’ve got to have clean equipment for proper operation, of course, but the shoe must be clean for it to glide smoothly and not tear the mat or disturb the joint. This is where, if you have the option to get a heated endgate, by all means, make it happen.

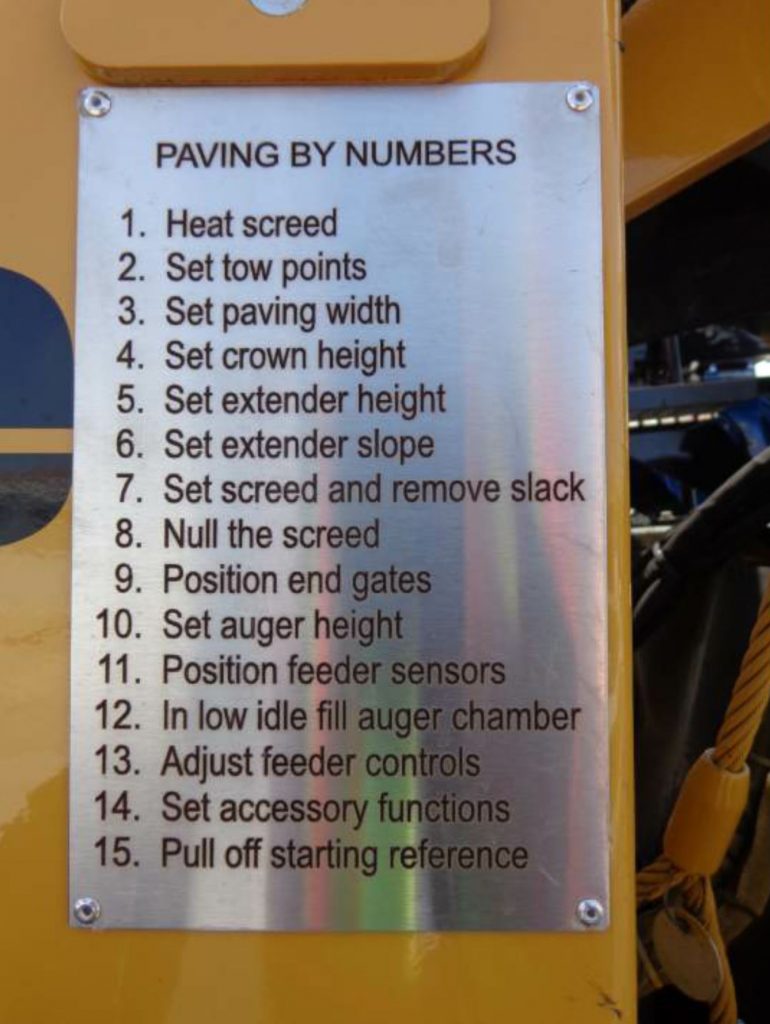

Of course, teach him to “pave by the numbers,” as our industry has been practicing for years, but the three basics listed here will help get him talking the same language as the rest of the crew. You will all talk about nulling out the screed. You will all talk about cleaning the shoe or endgate. These are aspects of the equipment he must learn and understand. This is a guide for some of the basics we do out there.

You want the new member of the crew to know the difference between the lute and the asphalt rake, and to know what each is best suited to accomplish to achieve a nice mat.

To pave by the numbers, follow this list:

- Heat the screed

- Set the tow point cylinders

- Set the paving width

- Set the crown height

- Set the extender height

- set the extender slope

- Set the screed and remove slack

- Null the screed

- Position the endgates

- Set the auger height (at 2 inches above what you’re going to lay)

- Position the feed sensors

- While in low idle, fill the auger chamber

- Adjust the feeder controls (once you get going)

- Set accessory functions

- Pull off the starter plates

John Ball is the proprietor of Top Quality Paving & Training, Manchester, New Hampshire. He provides personal, on-site paving consulting services around the United States and into Canada. For more information, contact him at (603) 493-1458 or tqpaving@yahoo.com.