How to Dump the Haul Truck (Without Making A Mess)

BY John Ball

Paving crewmembers can joke about haul truck drivers buying beer when they make a mess in front of the paver, but the sad fact is dumping a few tons on the ground costs everyone big money. Time, energy, segregated material and bad marketing are just a few of the expenses you can start calculating when you see a mound of hot mix dumped out.

It’s no laughing matter.

Before we start pointing fingers, let’s look at the remedy. A truck driver can keep his foot on the brake all day long and still have tonnage push the body out of the hopper. This doesn’t take the blame off the driver, but it requires more training.

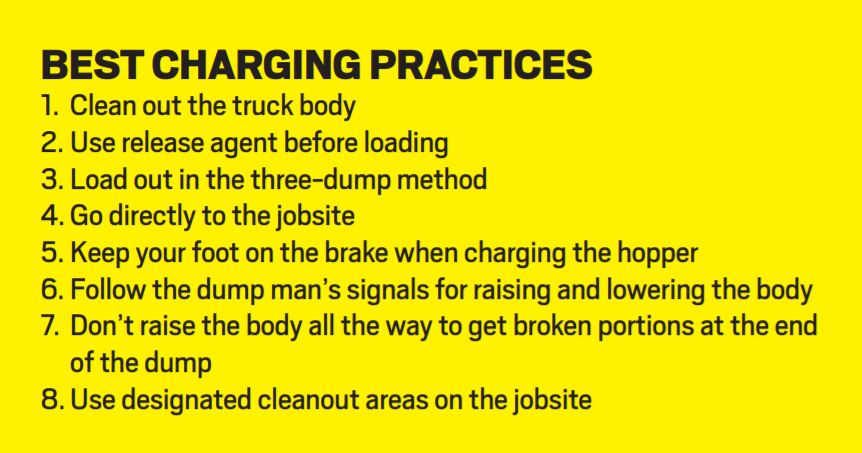

While the truck driver is still at the asphalt plant, he will spray the clean bed with a release agent to assist in the smooth flow of material later. Whether this is done under an automated spray system or at a hand-held wand station, the driver sets himself up for success by ensuring the body is free of caked material and then spraying it with release agent before loadout.

After loadout, the truck driver wastes no time dilly-dallying or stopping along his appointed route, but goes directly to the jobsite with the perishable product.

When the truck driver backs toward the paver, he comes to a stop within a few inches of the roller bars. The paver operator then gently inches forward to bring the roller bars in contact with the truck’s back tires. This calm and careful operation is the first step in the choreography for charging the hopper perfectly.

Next, the paver operator or dump man will signal for the truck driver to put on the brake. The brake prevents the pressure of the tons of moving mix from pushing the truck away from the paver.

Next, the paver operator or dump man will signal for the truck driver to raise the body of the truck a certain degree to move the material as a mass, flowing it into the hopper as a constant river of homogenous mix. There should be no mountains of mix falling in segregated clumps.

The paver operator can see what is taking place in the body of the truck at this point. He can see whether the material is moving as a mass or is breaking. If a portion of the mix “holds back” or breaks away and stays at the “top” of the truck, it presents a problem. By raising the truck bed higher, the truck driver will merely cause that portion to fall suddenly and violently down. It will shove the body away from the paver. Gravity will pull the material to the ground as the truck lurches forward. You will be left with a mess.

To avoid the mess, don’t get greedy. Avoid lifting the body to get that last portion. Instead, the paver operator or dump man should signal the truck driver to lower the bed and drive to the designated cleanout area.

This sounds like you’ve just wasted two tons of material. And, indeed, you have. But you would have wasted that two tons on the ground, along with 20 minutes of back-breaking labor while the traveling public drove by making a note of the company name emblazoned on your equipment. Instead of allowing trouble to brew, send trouble to the designated cleanout area and bring in the next truck to charge the hopper perfectly.

John Ball is the proprietor of Top Quality Paving & Training, Manchester, New Hampshire. He provides personal, on-site paving consulting services around the United States and into Canada. For more information, contact him at (603) 493-1458 or tqpaving@yahoo.com.