GSSI’s PaveScan RDM Asphalt Density Assessment Tool

BY AsphaltPro Staff

Achieving proper density is key to avoiding premature failures in your pavement. That’s why asphalt density assessment tools, like the PaveScan RDM from Geophysical Survey Systems Inc., Nashua, N.H., are so important. The PaveScan RDM automatically measures dielectric value in real time to detect poor uniformity and variations in density without the need to close off the work area. Here’s how it works.

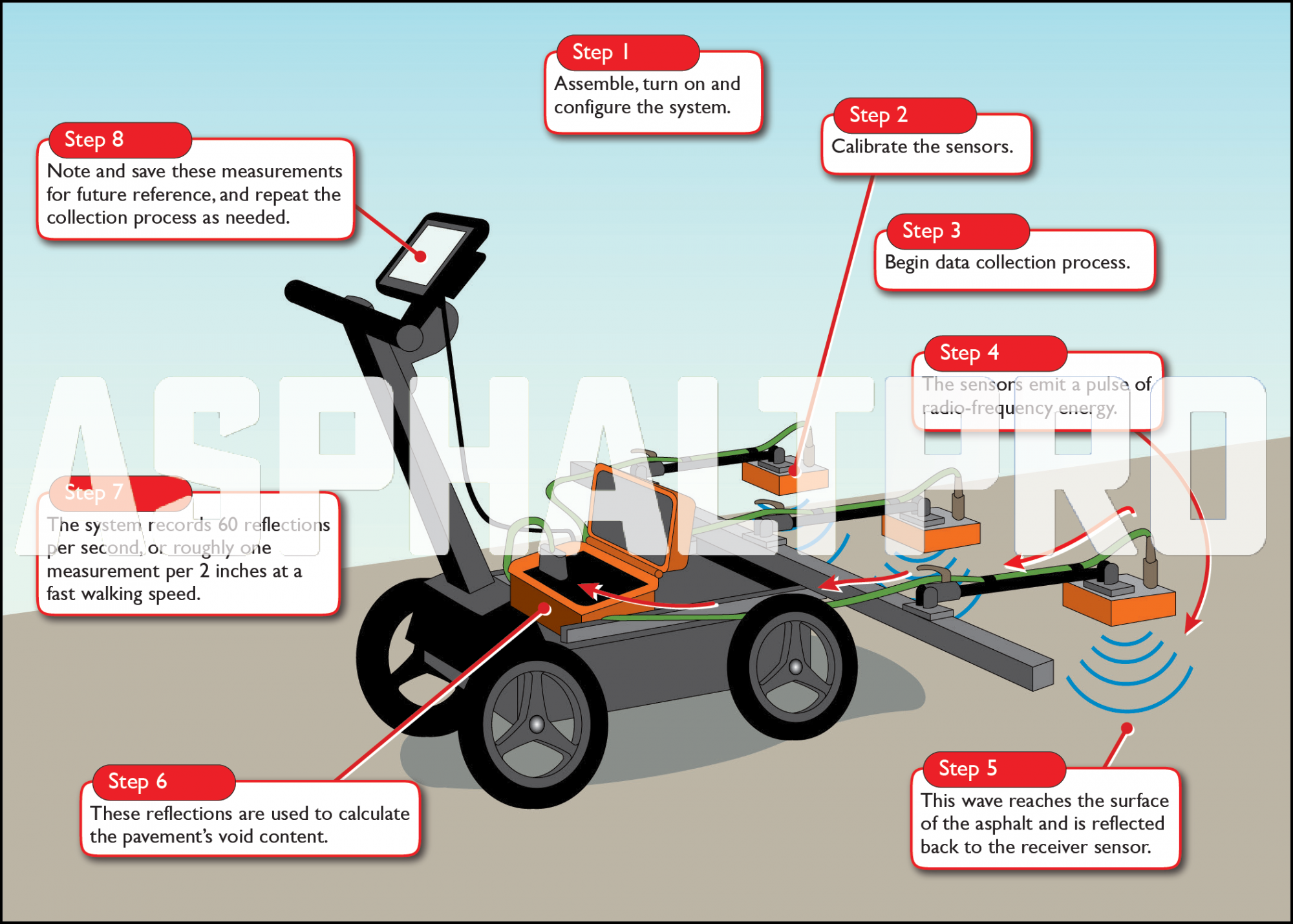

The first step when you arrive on the jobsite is to properly assemble, turn on and configure the system. The PaveScan RDM is available as either a single-sensor cart or an extended cart with three sensors. The sensors will take about 10 minutes to warm up, giving you time to bring the system to the collection site and place marks along the pavement collection area to make data collection easier.

Then, the system must be calibrated by lifting all three sensors to a 45-degree angle, collecting an air calibration file, and placing the metal plate under the sensor(s) to calibrate. Next, the user enters the appropriate information about the collection on the tablet and lines up the sensors at the start point. Now it’s time to collect data.

The PaveScan RDM uses RADAR (radio detection and ranging) technology to transmit and receive high frequency electromagnetic waves. A tiny pulse of radio-frequency energy is sent out using one or more sensors. This wave reaches the surface of the asphalt and is reflected back to the receiver sensor as a high frequency, electromagnetic reflection. The PaveScan RDM sensors record energy centered around 2.5 GHz.

Asphalt density variations create varying reflections that are picked up by the system. An integrated computer records the strength and time corresponding to the return of the reflected signals, which are used to calculate the asphalt dielectric values, and, ultimately, the new pavement’s void content, a relative indication of density.

The antennas are able to record the reflections from the asphalt at a rate of 60 reflections/second. This means that asphalt relative permittivity measurements every 2 inches can be obtained at a fast walking speed. While walking to the end point, it’s important to note dielectric changes and mark those spots for future reference before saving the data and repeating the collection process, as needed.

For more information, contact Rob Sommerfeldt at (603) 681-2072.