Falcon Asphalt Repair’s 250-Gallon Tack Tank Trailer

BY AsphaltPro Staff

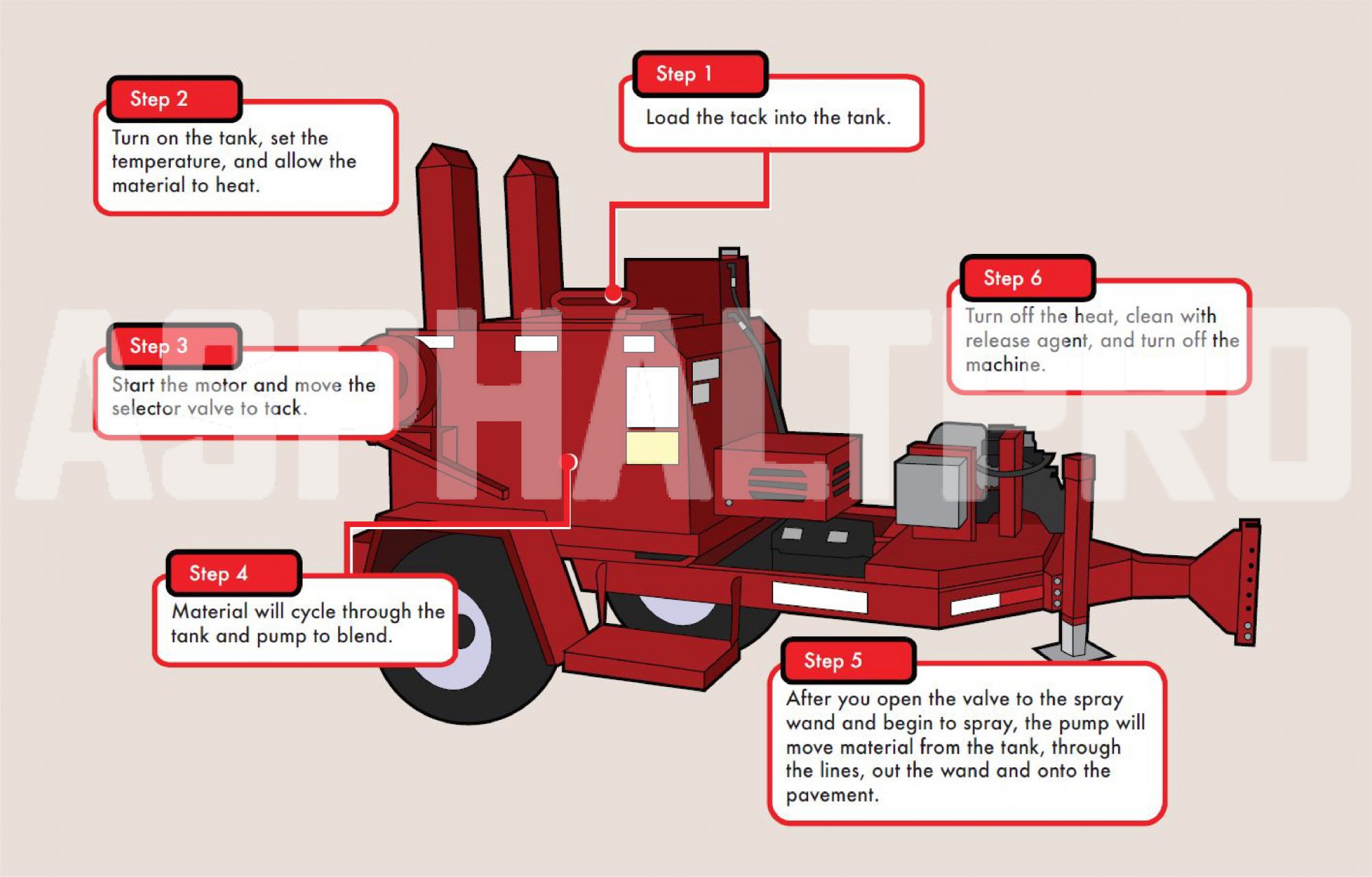

The team at Falcon Asphalt Repair Equipment, Midland, Michigan, has announced its new diesel tack tanks. Known for its hot boxes and recyclers, Falcon’s latest piece of equipment is available either trailer- or skid-mounted in both 150- and 250-gallon sizes. Here’s how they work.

First, you’ll need to load your emulsion-based tack material into the tank through the fill port located on the top of the tack tank. Then, you’ll turn on the tank using the toggle switch labeled “tack” in the control box and set the temperature using the digital control located inside the enclosure on the rear of the tack tank.

It will take approximately 10 to 20 minutes for the diesel-fired burner, located on the bottom of the tack tank, to properly heat the material depending on ambient temperatures. If material within the insulated tank drops 10 degrees below the set temperature, the thermostat will cycle back on to bring the material to the desired temperature.

After the material is thoroughly heated, it’s time to prepare to spray. Start the Honda motor located on the front left side of the trailer and move the selector valve to “tack.” Material will then move from the tack tank through the pump and back to the tank at a rate of 3 gallons per minute, allowing the material to properly blend. The blending process allows the tack to be applied evenly.

Then, open the valve to the spray-wand to spray the material. The pump will then suck material from the tank through the lines, out the spray-wand and onto the pavement.

After completing the job, it’s time to shut down and clean up. Turn off the heat and move the selector valve on the pump from spraying tack to spraying release agent through the system. There is an 8-gallon release agent tank located adjacent to the tack tank. Allow the release agent to cycle through until the tack is removed, and then shut off the motor.