Express Your RAP, RAS Content

BY The National Center for Asphalt Technology

A growing number of highway agencies are revising their asphalt specs to establish limits or trigger points for reclaimed asphalt pavement (RAP) and recycled asphalt shingles (RAS) based on how much the recycled binders contribute to the total binder content of mixes. Some agencies use the term “binder replacement” or “binder ratio” to convey this idea, which changes the emphasis to how the RAP and RAS binders influence mix characteristics and performance.

Historically, most people have expressed RAP and RAS contents as the percentage of the RAP or RAS by weight of total mix. For example, when someone said the mix had 10 percent RAP and 5 percent RAS, most people interpreted that to mean that the mix contained 10 percent RAP and 5 percent RAS by weight of total mix. From that interpretation, we could then determine how much RAP binder and RAS binder would be in the mix and how much RAP aggregate and RAS aggregate would be in the total aggregate blend.

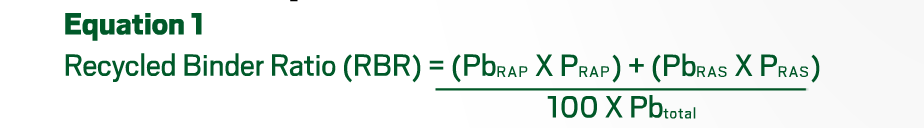

To calculate “binder replacement” or “recycled binder ratio” we need to know the asphalt contents of the recycled materials, the percentages of the RAP and/or RAS by weight of mix, and the total asphalt content for the mix. Equation 1 shows the math.

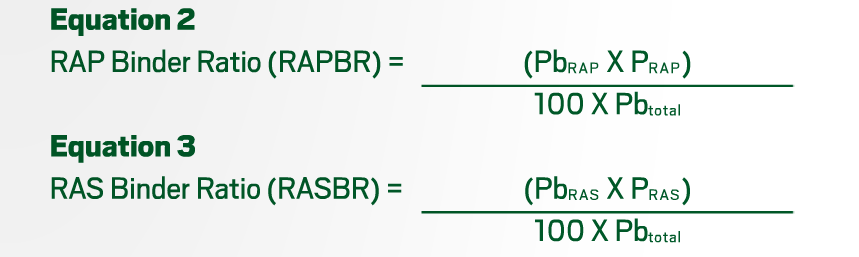

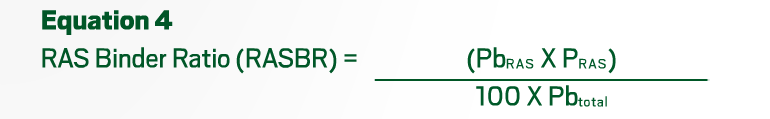

One concern with this approach is that it appears to equate RAP binder and RAS binder. Although they are both recycled asphalt materials and are stiffer than virgin paving grade binders, RAP and RAS binders are very different. RAS binders, whether from post-consumer or manufacturer’s waste, are much harder than RAP binders. Performance grading (PG) of recovered RAS binders is challenging because they are so stiff.* On the high temperature end, RAS binders from shingle manufacturer waste are typically in the range of 125 to 135oC and post-consumer RAS binders typically grade at 150 to 170oC. RAP binders typically grade in the range of 85 to 95oC on the high temperature end and -20 and -5oC on the low end. Making and testing bending beam rheometer (BBR) specimens with RAS binders is extremely challenging, so low temperature grading of pure RAS binders is questionable. Therefore, NCAT now suggests that RAP and RAS binder ratios be kept as separate quantities as shown in equations 2 and 3.

Another challenge with the binder ratio equations is that we don’t know the optimum asphalt content of the mix (Pbtotal) until we’ve completed the mix design. Therefore, we can’t determine the recycled binder ratios and we can’t know exactly how much RAP or RAS to use in the aggregate blending calculations. However, we can use the formulas and the spec limits to help us get started with the mix design.

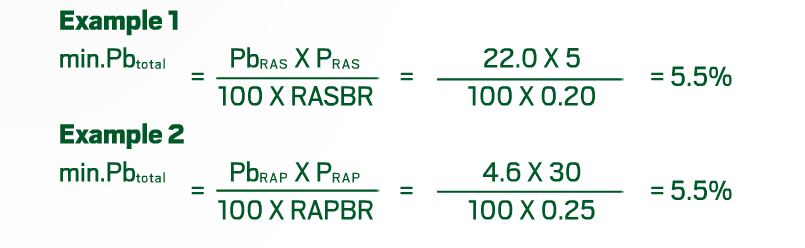

Let’s say that the spec limits surface mixes to a maximum RAS binder ratio of 0.20. If our RAS material has 22.0 percent asphalt and we want to use 5 percent RAS in the mix, then by rearranging equation 3, we can calculate the minimum total binder content to get a RASBR of 0.20.

Therefore, your mix design should start out with a trial asphalt content of no less than 5.5 percent.

For an example, using RAP, let’s say the spec allows a maximum RAP binder ratio of 0.25, the RAP has an asphalt content of 4.6 percent, and we would like to design a mix with 30 percent RAP by weight of mix. Rearranging equation 2, we can calculate the minimum total binder content to get a RAPBR of 0.25.

For either of these examples, if the trial mix design samples with 5.5 percent asphalt have air voids below 4.0 percent (or the mix design target air void content), then another aggregate blend or a lower RAP or RAS content will have to be tried.

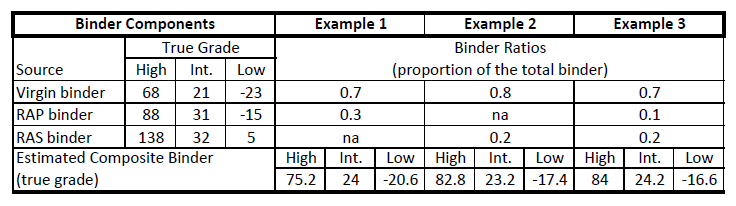

Another benefit of calculating RAP and RAS binder ratios separately is for estimating the properties of the composite binder when recycled binders are combined with a virgin binder. In the past, we used blending charts to estimate the combined properties of RAP and virgin binders. In effect, blending charts simply determine the weighted average of the properties of the two binders being blended. Unfortunately, blending charts are not helpful when more than two binders are combined. However, a weighted average can be easily calculated for any number of components. Table 1 shows the estimated true grade of composite binders for three example combinations of recycled and virgin binders. This approach, like blending charts, assumes complete blending of the component binders, which may not be the case.

For mix designs, we also need to determine how much the RAP and/or RAS contribute to the total aggregate blend. For RAP-only mixes, “by weight of mix” and “by weight of total aggregate” differ little when the asphalt content of the RAP and the mix are similar. However, for mixes containing RAS, the difference between “by weight of mix” and “by weight of total aggregate” is more significant.

First, let’s consider a mix with 20 percent RAP by weight of total mix. The asphalt content of the RAP is 5.1 percent and the asphalt content of the mix design is 5.6 percent. The percentage of total aggregate by weight of total mix is…

100-Pbtotal = 100-5.6 = 94.4%

Therefore, the percentage of RAP aggregate by weight of total blend is…

19.0%/94.4% = 0.201 or 20.1%

So saying “20 percent RAP by weight of mix” is almost the same as “20 percent RAP aggregate by weight of total aggregate.”

Now let’s consider an example with RAS. Let’s say the mix contains 5 percent RAS by weight of total mix. The asphalt content of the RAS is 21.3 percent and the asphalt content of the mix design is 5.6 percent. The fiber content of the RAS was determined to be 1.2 percent by weight of total RAS. The percentage of total aggregate by weight of total mix is…

100-Pbtotal = 100-5.6 = 94.4%

The percentage of RAS aggregate by weight of total mix is…

[PRAS X(100-(PbRAS+PfRAS))]/100 = [5.0 X(100-(21.3+1.2))]/100 = 3.9%

…where PfRAS is the fiber content of the RAS. Although the literature on shingles indicates that the fiber content of RAS may range from 2 to 15 percent, NCAT test results on RAS from various sources in the United States have found the fiber contents to range from 1 to 4 percent. Therefore, the percentage of RAS aggregate in the total aggregate blend is…

3.9%/94.4% = 0.042 or 4.2%

NCAT began using a shorthand notation for expressing RAP and RAS contents in asphalt paving mixes in 2014. Because we want to express both RAP and RAS contents as percentages of total mix and their contributions to the total binder content, NCAT offers the following notation:

A/B I D/E where:

A = RAP content as a percentage of total mix (%)

B = RAS content as a percentage of total mix (%)

C = RAP binder ratio (decimal)

D = RAS binder ratio (decimal)

For example, 20/5 I .18/.19 indicates that the mix contains 20 percent RAP and 5 percent RAS by weight of mix, respectively, and the RAP and RAS binder ratios are 0.18 and 0.19, respectively.

Table 1. Example of Calculating Weighted Average Composite Properties for Different RAP and RAS Binder Ratios

Source: NCAT’s Asphalt Technology E-News

*See the January 2016 AsphaltPro for articles regarding options for softening and rejuvenating recycled material binders.

Article reprinted from NCAT’s Asphalt Technology E-News, Vol. 26, No. 2