Eagle Crusher’s RapidDeploy™

BY AsphaltPro Staff

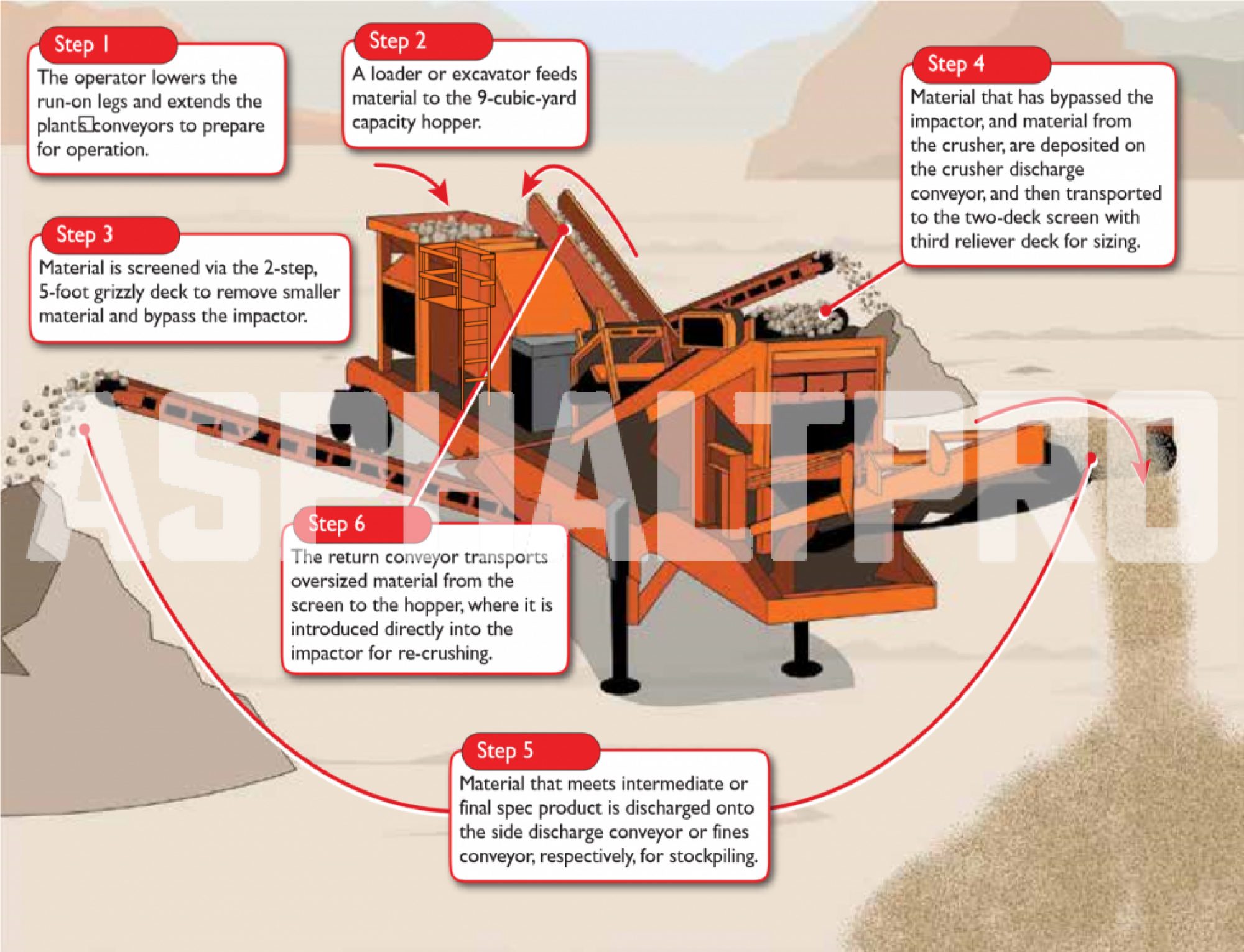

Material is dumped into the vibrating hopper. At the end of the hopper, material flows across the 2-step, 5-foot grizzly deck. Smaller material slips between the bars, allowing it to bypass the crusher and be screened first, reducing wear on the impactor.

Material that bypasses the impactor is deposited on the crusher discharge conveyor where it rejoins material crushed in the impactor and is transported to the two-deck screen with third reliever deck. The third reliever deck is two-thirds the length of the full screen decks to help bypass the close-to-size material through the screen to the absolute decks, while retaining the larger, oversized material. This gives the screen more opportunity to size the close-to-size material without blinding itself with too much oversize material.

Oversize material is returned via the return conveyor to the hopper, where it is introduced directly into the impactor for re-crushing.

Material that meets the producer’s intermediate or final specs is discharged off the side discharge or fines discharge conveyors, respectively, for stockpiling.

Optionally, smaller material that falls through the grizzly bars can be removed by the throw of a lever onto the optional grizzly discharge conveyor.

For more information, contact (800) 253-2453 or sales@eaglecrusher.com.