SmartWorkzones Makes Work Zones Safer

BY AsphaltPro Staff

Transporting material to and from the work zone isn’t our only transportation-related concern. We also need to worry about how traffic is getting through our work zones. Do drivers know where to go? What do to? When to do what? What’s in store ahead?

SmartWorkzone, developed by Savari Inc., Santa Clara, California, aims to make these questions clearer for drivers traveling through work zones.

“A smart work zone is a DSRC-based system that can enable efficient transmission of travel information messages upstream of the work zone to notify drivers approaching the area,” Navin Katta, technical lead at Savari Inc., said.

Although work zone total fatalities decreased by about 40 percent over the last decade, fatalities among those working in the work zone have remained consistent, according to the U.S. DOT’s National Highway Traffic Safety Administration (NHTSA) data.

“Not all fatalities happen in the work zone,” Katta said. “A lot of them are due to a work zone downstream, [which result in] cue backups or shock waves that arise from sudden braking.”

In addition to transmitting work zone notifications to nearby drivers, SmartWorkzones also collects vehicle data to compute travel time through a road segment, average speed and estimated starting line of congestion.

What this means for crew safety is additional safety features built into their existing roadside units that help communicate what’s to come to drivers in real time, so they know exactly when—and how much—to slow down if there’s congestion, and where exactly the construction work is taking place.

How It Works

The system’s roadside unit transmits messages using dedicated short-range communication, DSRC, directly to on-board units in nearby drivers’ vehicles.

“The intention is that all vehicles would have this technology,” Katta said. “It will be similar to how the seatbelt mandate was enacted.” Earlier this year, NHTSA made progress on its DSRC Notice of Proposed Rule Making with a goal to mandate DSRC in new light vehicles by 2020 as a phase-in plan with completion around 2025.

“The primary advantage of [all vehicles having an on-board unit] is the vehicle now becomes situationally aware,” Katta said.

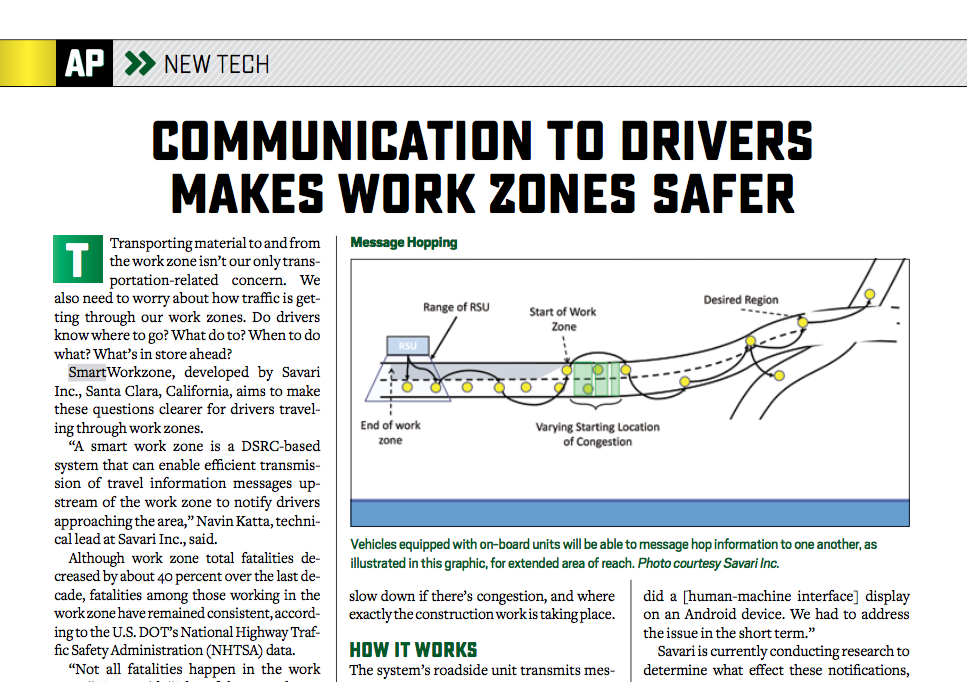

DSRC offers low latency and high reliability on a designated licensed bandwidth. Vehicles with the on-board unit will also “message hop” the information from the roadside unit to other vehicles.

Until then, SmartWorkzones can also send messages to nearby drivers’ smartphones.

“In the short term, in the absence of having a large number of DSRC-enabled vehicles, we can push the info over cellular networks as well,” Katta said. “That’s why we did a [human-machine interface] display on an Android device. We had to address the issue in the short term.”

Savari is currently conducting research to determine what effect these notifications, both on Smartphones and via on-board units, would have on driver distraction.

Industry Impact

Savari builds software and hardware solutions for car manufacturers and the automotive aftermarket to make “transportation predictive, safer and more efficient,” according to its website. Savari was founded in 2008 and in 2015 received $8 million in Series A funding from car manufacturers in the U.S. and China.

Also known as vehicle-to-everything, or V2X, technology, this industry is expected to grow to $36 billion by 2025, according to a report by Navigant Research. Other uses for V2X technology include emergency vehicle warnings, intersection collision warnings, pre-crash sensing, fleet management and electronic toll collection.

This article was written based on a July 12 webinar hosted by the Transportation Research Board on using technology for practical purposes in work zones.