ASGCO®’s Tru-Trainer® Tapered Troughing Idler

BY AsphaltPro Staff

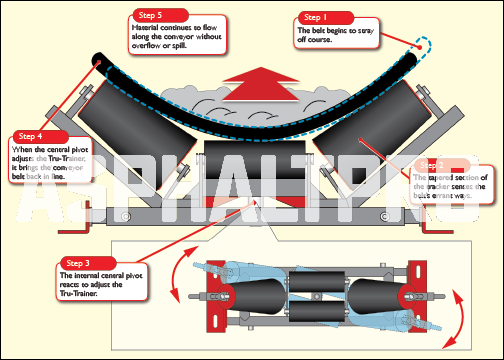

When conveyor belts carrying heavy material start to wander off track, the result can be disastrous, costly downtime. The conveyor products division at ASGCO®, Allentown, Pa., designs conveyor belt tracking systems including the Tru-Trainer® belt-alignment system to prevent belts from wandering too far off track. The patented ASGCO Tru-Trainer Tapered Trougher offers tracking performance on the load-carrying side and is the result of more than 10 years of design and innovation. Here’s how it works.

The conveyor belt with material on top runs along the Tru-Trainer belt tracking system. As the belt begins to skew offline, the Tru-Trainer springs into corrective action.

Corrective action happens because the skewing belt makes contact with the tapered section of the tracker. The tracker has an internal central pivot with an anti-seize compound inside. Tru-Trainer®’s central pivot mechanism is designed to remain perpendicular to the plane of the belt at all times, so when the force generated by the difference of the peripheral speeds on and off the taper wing causes the tracker beneath the belt to pivot, it adjusts—pivots—to remain perpendicular.

The end result: The pivot brings the belt back to its correct and centered position.

The Tru-Trainer Tapered Troughing Idler specifically is designed to align the load-carrying side of conveyor belts to reduce spillage. The combination of the tapers and unique center pivot, provide fast, reactive and continual tracking in all conditions, both wet and dry, and can be individually replaced as wear occurs. The Tru-Trainer Tapered Troughing Idler is available in high abrasive, rubber lagging 1/2″ thick or polyurethane lagging ½-inch (Red). Also available in fire retardant lagging.

For more information, contact us at (800) 344-4000 or info@asgco.com.