Sep 19, 2022

Get Consistent Results in the Plant Lab—Part 2 for Gyratory Specimens

BY AsphaltPro Staff

For the toolbox tips this month, we’re concentrating on quality control/quality assurance. When in the lab, look at the way you make gyratory specimens.

First.

Be careful when “handling” the mix so you prevent segregation from the get-go. You might want to re-think the use of a funnel for filling the mold. The free-fall through the funnel can encourage material segregation. Instead, you can place the hot mix in a half-round of PVC pipe, lay the mold on its side, and then slide the loaded PVC pipe into the mold. When you stand the mold upright, the mix falls as a mass into the mold.

Or you can place the hot mix on a flexible mat, roll the mat into a tube, lay the mold on its side, and then slide the rolled mat/tube into the tube. Then you discharge the mix into the mold by standing the mold upright.

Second.

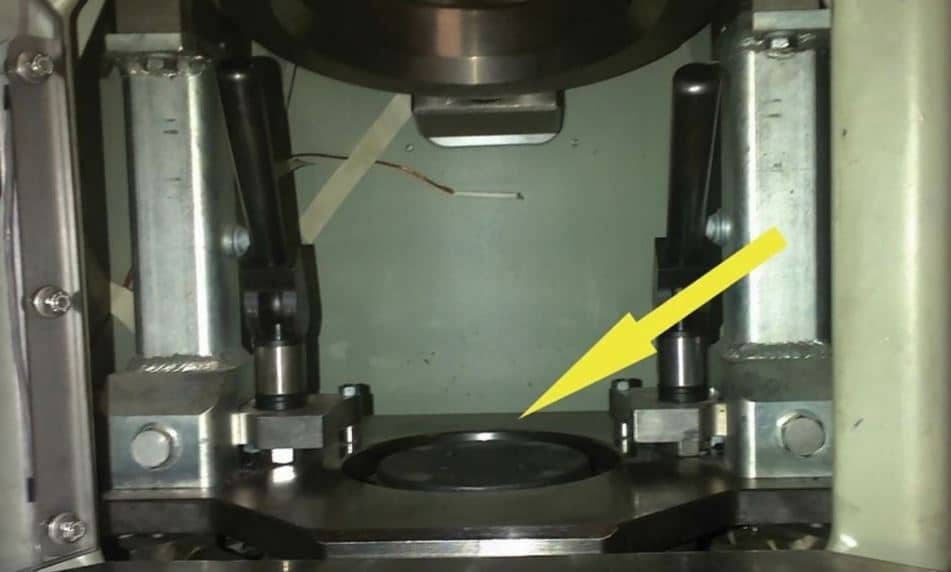

Double-check the gyratory compactor’s internal angle. AASHTO T312 wants it at 1.16 degrees (+0.02 degrees). If the angle is too low, you’ll get less compaction of the specimen.

Third.

Double-check the gyratory compactor’s operating pressure. AASHTO T312 Section 4.1 wants it at 600 +18 kPa. If compaction pressure drops, you’ll lower the bulk specific gravity.

You want to get the compaction of the specimen consistently correct before testing can even begin.

Sign up to receive tips like this to your inbox each week.