We’ve discussed the advantages of using the popular “Pave by the Numbers” method of starting the paving shift in the pages of AsphaltPro magazine and in these toolbox tips. It’s a step-by-step method for making sure you get all the bits and pieces lined up to take off from a starter pad or starter plate without leaving segregation behind the screed. There are other advantages, of course.

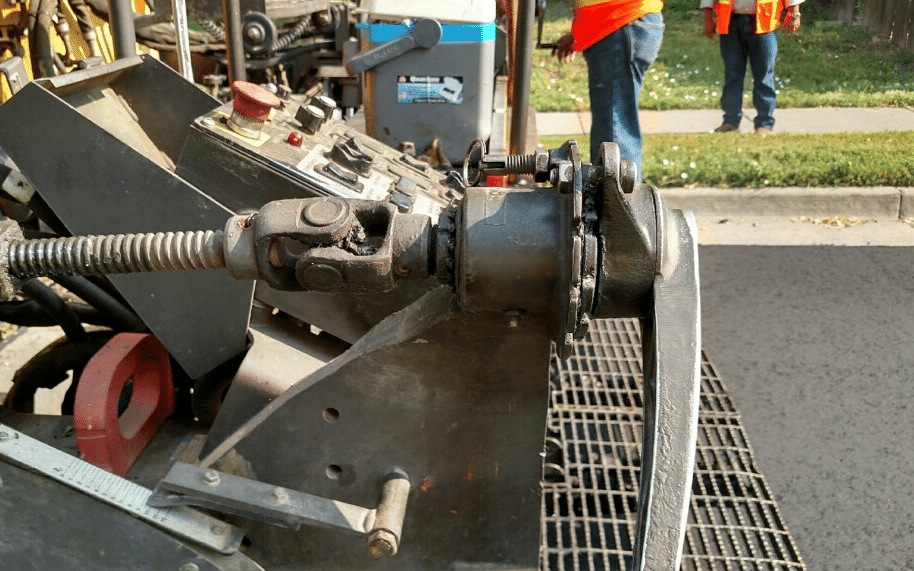

One of the advantages is getting a straight line of pull, which helps reduce your chances for a bump or dip in the new mat. To achieve the straight line of pull at take-off, focus on the tow point cylinder. This mechanism is the point where the towing arms can manipulate the position of the screed in conjunction with the paver.

If you adjust the tow point cylinder, you adjust the “posture” of the screed. Bryce Wuori, CEO of Pavewise, reminds us that the screed is designed to float on the asphalt mat, and we want this process to be as fluid as possible. When there is friction between your paver and screed, this is transferred down into the asphalt mat causing potential defects.

With the heated screed up in the air, set the tow point cylinders on the left and right side of the paver based on the mat thickness you’ll be paving. You want the screed to be free-floating atop the mix with a nose-up posture. This is commonly called the “angle of attack.” Depending on the thickness you’re paving, you want the nose to be “up” a quarter of an inch, allowing the mix to flow underneath. You set the tow points to the correct height before putting the screed down.

QUICK TIP:

Let’s say you want to find the sweet spot where your screed and tractor are lined up nicely together for the perfect line of pull. Before the paving day begins, set the screed down on a flat pad and measure the height from the ground (or grade) to the pivot point for the screed; you’re looking at where it pivots around the depth crank. Bring your tow point up or down to get it to that same distance. Look at your ruler on your tow point. That’s your straight line of pull.

Wuori said good paving operators can often feel if there is friction between the paver and screed depending on how the paver is driving or pulling. “I have found you can look at the tow arm vertical mounts on each side to see how consistently the screed is pulling behind the paver. They should have a close to equal amount of space on each side between the mount and paver to show the line of pull is true. If one side is pushed up against the paver, then either the line of pull is not correct, or we have an issue with the head of material in front of the screed.”

Sign up to our Toolbox Tips newsletter to receive tips like this to your inbox each week!