Aggregate Morphology Offers Recommendations for SMAs

BY Yufeng Liu, Harikrishnan Nair, D. Stephen Lane, Linbing Wang, and Wenjuan Sun

Hot-mix asphalt (HMA) pavement mixes are composed of up to approximately 90 to 95 percent mineral aggregates by weight and up to 80 to 90 percent aggregates by volume. The mineral aggregate plays a vital role in the mechanical performance of asphalt pavements.

According to the basic material properties and composition of the aggregate skeleton, asphalt concrete mixes can be classified as dense graded or gap graded.

Dense-graded mixes, also known as Superpave mixes in Virginia, are asphalt mixes with a uniform distribution of aggregate sizes along the maximum density line. Stone matrix asphalt (SMA) is a gap-graded HMA with a high percentage of coarse aggregate and high asphalt content. Gap-graded mixes are characterized by a non-uniform distribution of aggregate sizes. These mixes contain aggregates retained on the larger and smaller sieves but with little aggregate retained on the middle sieves. As with dense-graded mixes, gap-graded mixes are identified based on nominal maximum aggregate size (NMAS).

SMA is the most common gap-graded mix used in Virginia and is composed of a gap-graded aggregate that is intended to maximize rutting resistance and durability with a stable stone-on-stone skeleton held together by a rich mixture of asphalt binder, mineral filler and cellulose fibers. SMAs are recommended only for placements in heavy traffic conditions because of their higher cost. The rut resistance of SMA is achieved through the stone-on-stone contact by specifying the coarse aggregate fraction of the mix to be between 70 and 80 percent; durability is enhanced through the rich asphalt mastic. To ensure durability of SMA mixes, a stiff mastic containing a high liquid asphalt content (6.3 percent minimum specified in Virginia for SMA-9.5), a high amount of mineral filler (9 to 11 percent), and a small amount of cellulose fibers (minimum of 0.3 percent) is typically specified.

SMA mixes have been used extensively by the Virginia Department of Transportation (VDOT) throughout Virginia since 2003. The field performance of SMA in Virginia has been generally excellent, with reported service lives of 15 to 18 years, according to a paper by McGhee et al in 2010. However, several SMA pavements have experienced premature failures. McGhee et al, in 2010, identified factors related to both pavement structure and material as causes for the poor performance of some VDOT SMA-surfaced pavements. Material-related failures including flushing, rutting and surface distortions were observed at intersections for an SMA-9.5 mix with a performance grade (PG) 70-22 binder. SMA mixes with larger, coarse aggregates (SMA-12.5) appeared to perform better than SMA mixes with finger aggregates.

Tests and studies ensued.

The State of Flat and Elongated Aggregate Requirements for SMA

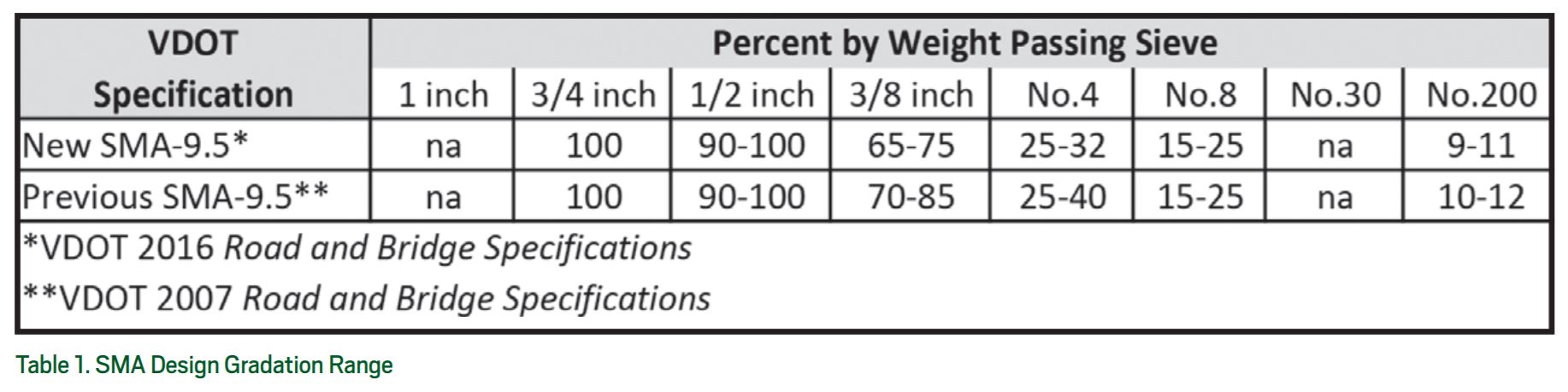

VDOT adopted a new gradation for SMA-9.5 mixes in 2012. The new gradation, along with the previous gradation, is shown in Table 1, on page xx. The primary change was the reduction of the maximum percent passing the No.4 sieve from 40 percent to 32 percent. In addition, minor changes were made with regard to the 3/8-inch and No.200 sieves. The purpose of changing percent passing for the 3/8-inch and No.4 sieves was to coarsen the mixture and improve stone-on-stone contact.

An additional requirement placed on coarse aggregates for use in SMA mixes was a limitation on the percentage of particles with a high aspect ratio, commonly referred to as flat and elongated particles. The purpose of this requirement was to avoid extreme shapes that could impair the ability of the aggregate to pack into a stone-on-stone skeleton or break easily during compaction, changing the aggregate gradation. Compliance with the flat and elongated requirements is currently determined by manual measurement of individual particles. Advanced imaging technology with a computer-automated system is a promising tool in providing precise data for aggregate morphological characteristics. With the ability to characterize the aggregate morphology objectively and quantitatively, without tedious human interaction, more effort can be focused on simple performance tests and wheel tracking tests. The laboratory performance-based results can be analyzed to link better the aggregate morphological characteristics with the mechanical performance of asphalt mixes. A better and more scientific understanding of the effect of aggregate morphology on the performance of asphalt mixes is needed to reduce the production costs for mixes and improve long-term pavement performance.

Purpose and Scope

The purpose of this study was to examine VDOT’s revised grading specs for the design of SMA mixes with smaller aggregates and the impact of aggregate morphology on the structural stability of the mix. A limited suite of aggregates representing the range of particle morphology typical of Virginia sources was characterized using an image analysis system. SMA mixes designed and produced by different contractors using aggregates from different quarries in Virginia were included in the study. SMA mixes and samples of the aggregates used in production were obtained for a lab evaluation of the structural stability and aggregate characteristics of the mixes.

The study had a number of objectives.

- Assess the volumetric properties, binder properties and lab performance of SMA mixes produced under the revised gradation spec.

- Quantify coarse aggregate morphological characteristics, including sphericity, flatness ratio, elongation ratio, flat and elongated particle ratio, angularity, and texture using an image analysis system and the uncompacted void content.

- Correlate aggregate morphological characteristics captured by image analysis techniques with the mechanical performance of SMA mixes obtained from the lab performance-based tests.

- Correlate aggregate morphological characteristics captured by image analysis techniques with the uncompacted void content of coarse aggregates.

- Assess the field performance of these mixes using data from VDOT’s Pavement Management System (PMS).

We started with a literature review, searching various transportation-related databases.

SMA-9.5 mixes were collected from field projects that were paved in 2013, 2014 and 2015. SMA mixes were produced in accordance with VDOT’s specs for the SMA mix design published in 2016. Virginia aggregates used for mixes quarried at Bealeton, Stuarts Draft, Piney River, Leesburg, Goose Creek, Chantilly and Garrisonville were also collected. The three types of asphalt binder selected were PG70-22, PG76-22 and PG76-28 high polymer. The asphalt binder content in each SMA mix varied around 6.3 to 6.4 percent by weight, except for one mix in which it was 6.8 percent. There were a total of 23 types of coarse aggregate in the SMA mixes. These aggregates mainly included the following rock types:

- Aplite

- Limestone (No.10 screenings)

- Quartzite

- Arkose

- Diabase

- Amphibolite

The Bottom Line

All SMA-9.5 mixes examined in this study met the criterion of VCAMIX < VCADRC when a breakpoint sieve of 2.38 millimeter (mm) was used for calculation. Most of the SMA-9.5 mixes also met VDOT’s spec for the SMA-12.5 gradation requirement, which shows that using certain gradations, a producer can meet VDOT requirements for both SMA-9.5 and SMA-12.5 mixes. Hence, VCAMIX was calculated based on a 4.75 mm breakpoint sieve (breakpoint for SMA-12.5 mix). Three mixes did not meet the criterion of VCAMIX < VCADRC, indicating loss of stone-on-stone contact.

The fineness modulus for the gradation (per ASTM C125) (ASTM, 2017) was determined for all mixes and ranged from 5.08 to 5.38. (The literature review found mixes performed poorly in rutting when the fineness modulus was less than 5.0.)

Volumetric results showed that as the percent passing the 4.75 mm sieve increases, the VMA of the mix decreases and VCAMIX increases.

The shape factor results from the improved FTI system, including sphericity and flatness ratio, were in good agreement with manual measurements using a Vernier caliper. Aggregates used in the mixes included in this study were produced in quarries equipped with an array of crushing equipment including jaw, impact, cone and gyratory crushers from a variety of rock types. The aggregates met the flat and elongated particle requirement.

Overall, there was no major difference in the dynamic modulus values between different mixes.

The flow number results under the unconfined condition varied greatly, indicating the different rutting resistance potentials of these SMA mixes; flow numbers under the confined condition for all types of SMA mixes were the same. In both the confined and unconfined flow number tests, polymer-modifed binders showed a lower slope compared to PG70-22 binders, indicating better rutting resistance.

All mixes showed lower rut values in the APA test than the criterion of 4.0 mm for Virginia’s SMA.

Based on beam fatigue testing, SMA mixes with polymer-modified binder showed excellent fatigue performance.

All mixes showed a maximum number of cycles of 1,200 in the Texas overlay test, suggesting excellent reflection crack resistance of these mixes.

Polymer-modified asphalt showed low Jnr values in MSCR testing, indicating better performance of these binders with regard to rutting and the accommodation of temperature variations and extreme loading conditions.

Statistical results showed that the flow number test parameter Log(FN) was correlated with the aggregate morphological characteristics (S, FER, AF and TF).

The linear regression analyses between the weighted mean morphological characteristics (S, FER, AF and TF) and the FNS of all SMA mixes were performed with or without grouping FNS data based on performance grade. FNS increased with increased weighted mean FER values and decreased with increased weighted mean S, AF and TF values. The lower the FNS, the better the rutting performance.

Statistical results showed that the fatigue parameter Log(NOC) was correlated with the morphological characteristics (AF and TF).

Linear regression analysis indicated that the morphological characteristics correlated well with the uncompacted void content of coarse aggregates with size ranges of 4.75 to 9.5 mm and 9.5 to 12.5 mm. Both regression models for these two aggregate size ranges showed that the uncompacted void content increased with a decrease in angularity for coarse aggregates.

Conclusions

Using the appropriate breakpoint sieve for the VCAMIX calculation is important for assessing the presence of good stone-on-stone contact and a denser coarse aggregate fraction in SMA mixes. SMA requires good stone-on-stone contact of the coarse aggregate to be able to function as a durable and rut-resistant mix.

It is important to recognize a distinction between the breakpoint sieve established by the design procedure (Virginia Test Method 99) and what could be called the “effective” breakpoint sieve, the smallest sieve used in the VCAMIX calculation, because the calculation includes only the established breakpoint and larger sieves on which 10 percent or more material is retained.

For example, the established breakpoint sieve for the SMA-9.5 mixes is the 2.36 mm sieve; however, for a gradation where less than 10 percent material is retained on the 2.36 mm sieve, the 4.5 mm sieve is the “effective” breakpoint sieve and the material retained on the 2.36 mm sieve is not included in the VCAMIX calculation.

The improved FTI system can accurately quantify morphological characteristics of aggregates. The technology is well suited for research work and should be used in studies where aggregate morphology is of interest. However, it is not commercially developed such that it could be implemented for routine practice.

SMA mixes consisting of more spherical (equant), less flaky aggregates with more angular and rougher textured surfaces have better rutting resistance. SMA mixes consisting of more angular and rougher textured aggregates have better fatigue characteristics.

Among morphological characteristics, flatness ratio, elongation ratio and texture have the greatest effect on uncompacted void content for coarse aggregated retained on the 4.75 mm sieve, whereas elongation ratio and angularity have the greatest effect on void content for coarse aggregates retained on the 9.5 mm sieve.

Based on lab test results, with polymer-modified binder, better rutting resistance can be obtained even if the aggregate morphological characteristics are slightly less favorable.

From these conclusions, we have the following three recommendations.

First, VDOT’s materials division should continue with the revised gradation changes for the SMA 9.5 mix along with other specifications for aggregate and volumetric requirements. If the SMA-9.5 mix also meets the gradation requirement for an SMA-12.5 mix, then the VCAMIX criterion should be checked using the 4.75 mm sieve as the breakpoint sieve to ensure stone-on-stone contact. For SMA-9.5 mixes that are not coarse enough to be interchangeable with SMA-12.5 mixes, the 2.36 mm sieve should not be used as the breakpoint sieve.

With regard to this first recommendation, no change is needed, as the current VDOT specification included the new gradation change. Selection of the breakpoint sieve is effectively controlled in Virginia Test Method 99, wherein the material on the breakpoint sieve is considered as coarse aggregate only if it exceeds 10 percent retained.

SMA is very sensitive to changes in the material passing the respective “breakpoint” sieve. Excessive material passing the breakpoint sieve will cause the mix to lose stone-on-stone contact. Implementing this first recommendation will ensure stone-on-stone contact and reduce rutting.

Second, VDOT’s material division should encourage the use of polymer-modified binders when the SA-9.5 mix is specified to increase fatigue life and reduce rutting. With regard to this second recommendation, VDOT’s materials division implemented this by making a note in the asphalt mix selection guidelines. Implementing the second recommendation will contribute to increased fatigue and rutting resistance of SMA mixes.

Third, VDOT’s materials division and the Virginia Transportation Research Council (VTRC) should consider initiating an investigation to study the feasibility of using an upper limit on the uncompacted void content of aggregates in addition to or as an alternative to the flat and elongated particle requirement. With regard to this third recommendation, a research needs statement will be developed for VTRCs Asphalt Research Advisory Committee to consider at its fall 2019 meeting. The benefit of implementing the third recommendation is the possible adoption of a simpler method to avoid aggregates having excessive aspect ratios.

This article is provided in cooperation with the U.S. Department of Transportation’s Federal Highway Administration and the Virginia Transportation Research Council, which is a partnership of the Virginia Department of Transportation and the University of Virginia since 1948. Yufeng Liu is a teaching assistant at Virginia Tech. Harikrishnan Nair, Ph.D., P.E., is a senior research scientist at Virginia Transportation Research Council. D. Stephen Lane is an associate principal research scientist at Virginia Transportation Research Council. Linbing Wang, Ph.D., P.E., is a professor at Virginia Tech. Wenjuan Sun, Ph.D., is a research associate at Lehigh University. They published their final report VTRC 19-R15 “Influence of Aggregate Morphology and Grading on the Performance of 9.5-mm Stone Matric Asphalt Mixtures” May 2019.