Van der Graaf’s Belt Cleaner

BY AsphaltPro Staff

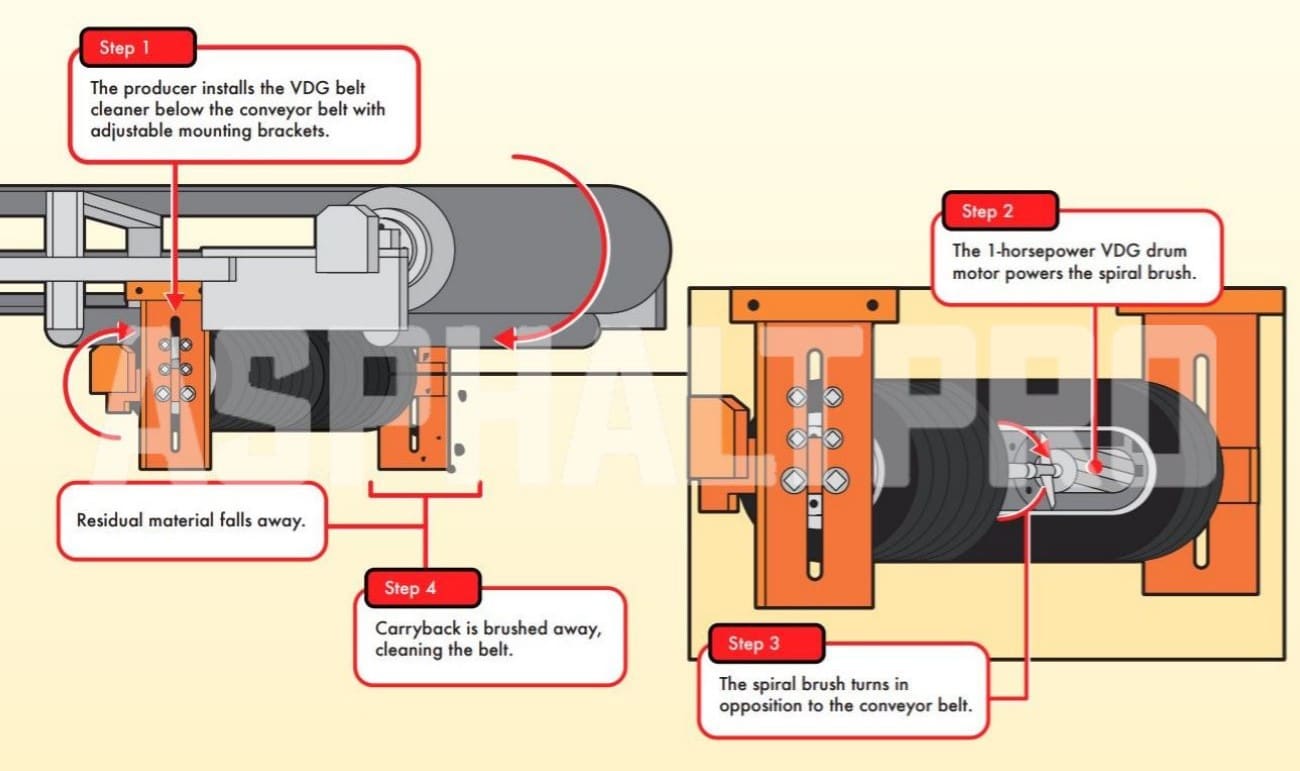

Producers lose efficiency to carryback on conveyor belts. One way to extend the life of the belt and prevent carryback is to install a belt cleaner. The team at Van der Graaf (VDG), Vollenhoven, Netherlands, with manufacturing facilities in the United States and Canada, created the VDG belt cleaner for this purpose. Here’s how it works:

First, the producer chooses a belt cleaner with a brush width from 26 to 74 inches to fit belts 24 to 72 inches wide and uses adjustable mounting brackets to install it beneath the conveyor belt that is to be safeguarded.

The belt cleaner’s completely sealed, 1-horsepower motor spins the drum—from 164 to 630 feet per minute on the four narrower models; from 236 to 614 feet per minute on the four wider models.

The 10-inch-diameter, replaceable, rotating spiral brush turns in a direction that is in opposition to the belt’s direction of travel. The Nylon 66 continuous spiral brush dislodges residual materials from belts that have cleats, lacing, repair patches or sidewalls. The residual material falls to a pile or waiting hopper beneath the belt cleaner.

For more information, visit https://www.vandergraaf.com/products/beltcleaner or call (888) 326-1476.