SealMaster’s CrackPro RMV

BY AsphaltPro Staff

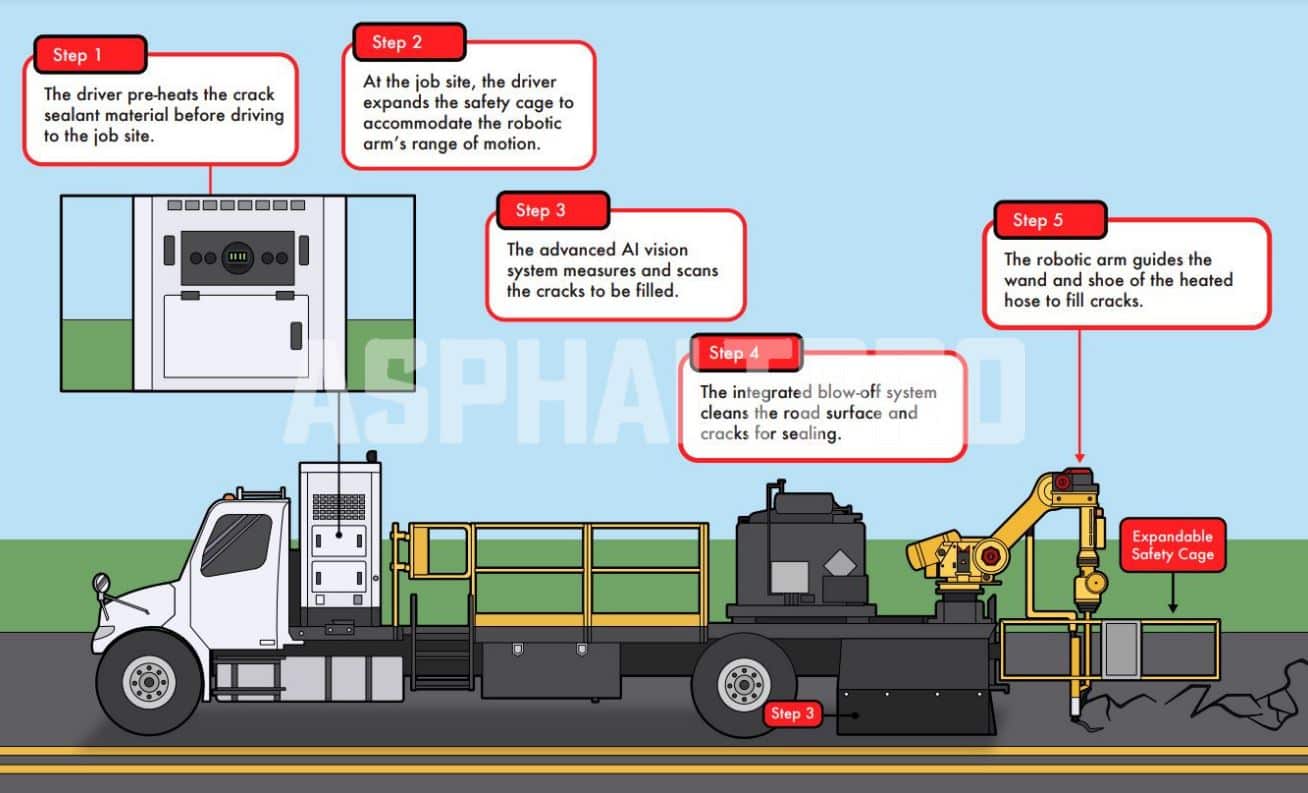

Keeping maintenance crewmembers out of harm’s way is easier to do if you can automate the labor-intensive portions of pavement maintenance or turn those activities over to a machine. After seeing a crack sealing crew working alongside traffic during his commute to work one day in 2019, Todd Hendricks of Pioneer Industrial Systems, headquartered in Alvordton, Ohio, came up with the concept of a robotic maintenance vehicle, developed a RMV division of his company and partnered with SealMaster to make the vehicle a reality. Engineers integrated an R2000 onto a truck chassis and equipped it with components to create an efficient form of work. Here’s how this award-winning system works:

First, a worker pre-heats the crack sealant onboard the unit so the material is ready to use upon arrival at the job site.

A driver pulls the CrackPro RMV—which is a full truck chassis equipped with a FANUC R2000 robot, generator, integrated blow-off system, custom Crack Pro 260, LED safety lights, and rear safety cage—to the work zone where crack sealing is to be performed.

Next, the safety cage is expanded hydraulically from the cab of the truck to accommodate the FANUC R2000 robot’s range of motion.

The CrackPro RMV’s advanced AI vision system measures and scans cracks in the area where maintenance is to be performed.

With this gathered data, the system guides the automated blower system in cleaning the cracks for sealing. The system communicates with the robotic arm, guiding the wand and shoe of the heated hose to dispense crack sealant. It controls material flow.

A second worker stays on the back of the unit to monitor application and replenish the crack sealant as needed throughout the shift.

For more information, visit sealmaster.net