International Asphalt Industry News Roundup

BY AsphaltPro Staff

UAE Construction Crisis

GlobalData’s MEED shared that a first-quarter decision by Abu Dhabi Airports Company to pull contractors’ performance guarantees for the Midfield terminal building project at Abu Dhabi International airport is another sign that the United Arab Emirates’ construction sector is in a full-blown crisis. Colin Foreman, the deputy editor of GlobalData’s MEED, said: “Over the past five years, there has been a growing trend of international contractors exiting the market after sustaining financial losses, and several regional heavyweights have teetered on the brink of bankruptcy. The most high-profile contractor to be affected is Dubai-listed Arabtec Holding as its shareholders voted to liquidate the contractor last year.

“The construction crisis is now an issue for the financial sector,” Foreman continued. “The Arabtec liquidation has left banks smarting, with billions of dirhams of exposure to the company. Rather than drawing a line under the problem with liquidation, the problems are getting worse….As banks struggle to keep up with events, they will become increasingly wary of any new exposure. Starved of cash, more projects will stall and more companies will fail. The construction crisis will get worse before it gets any better.”

Lira Proves UAE Point

Following the sacking of the Turkish Central Bank chief and a steep fall in the Turkish Lira early in 2021, Moustafa Ali, an economist at GlobalData, offered: “While the Central Bank chief’s orthodox monetary policy framework had won back the confidence of the markets, overseeing a sustained recovery in the lira, the outlook for the Turkish economy and construction industry appears to have worsened significantly following the sacking of the outgoing governor.

“GlobalData expected the industry to grow by 3.8 percent in 2021, but these latest developments have negatively affected the previous outlook…With Turkey’s policy credibility likely to worsen in the coming weeks, with the expected cut in the key interest rate, the country is expected to see major outflows of capital in the coming weeks and months. This is likely to spill over into the construction industry, with projects now set to become less profitable and financial conditions likely to tighten.”

Ali explained: “The strengthening of the lira was expected to provide a substantial boost for the Turkish economy and construction industry in 2021. While the Turkish economy was among one of the few major economies that grew in 2020, the construction industry recorded a contraction of 3.5 percent in 2020. The plunge in the lira is expected to significantly hamper growth in the industry this year, with the cost of raw materials and other imported goods set to rise markedly.”

Metso Outotec Expands

Metso Outotec has received an order for a heavy-duty mine conveyor system in South America, according to a March 22 release. The delivery consists of overland conveyors, including a 2-kilometer single flight conveyor. Equipment provided in this package runs at speeds of up to 6 meters per second with a delivery capacity of over 9,000 tph. The order value is approximately EUR 10 million and it has been booked in Minerals’ Q1/2021 orders received.

Meanwhile, Metso Outotec and its distribution partner BIA Group expanded their aggregates distribution coverage to Africa, according to a March 30 release. Metso Outotec’s stationary and mobile equipment, spare and wear parts coupled with BIA’s technical expertise and local presence are available for aggregates customers in West and Central Africa. The two companies have successfully partnered in the Benelux region since 1930.

Sraloong Construction Builds Thai Highways, with Help from Ammann EasyBatch Plant

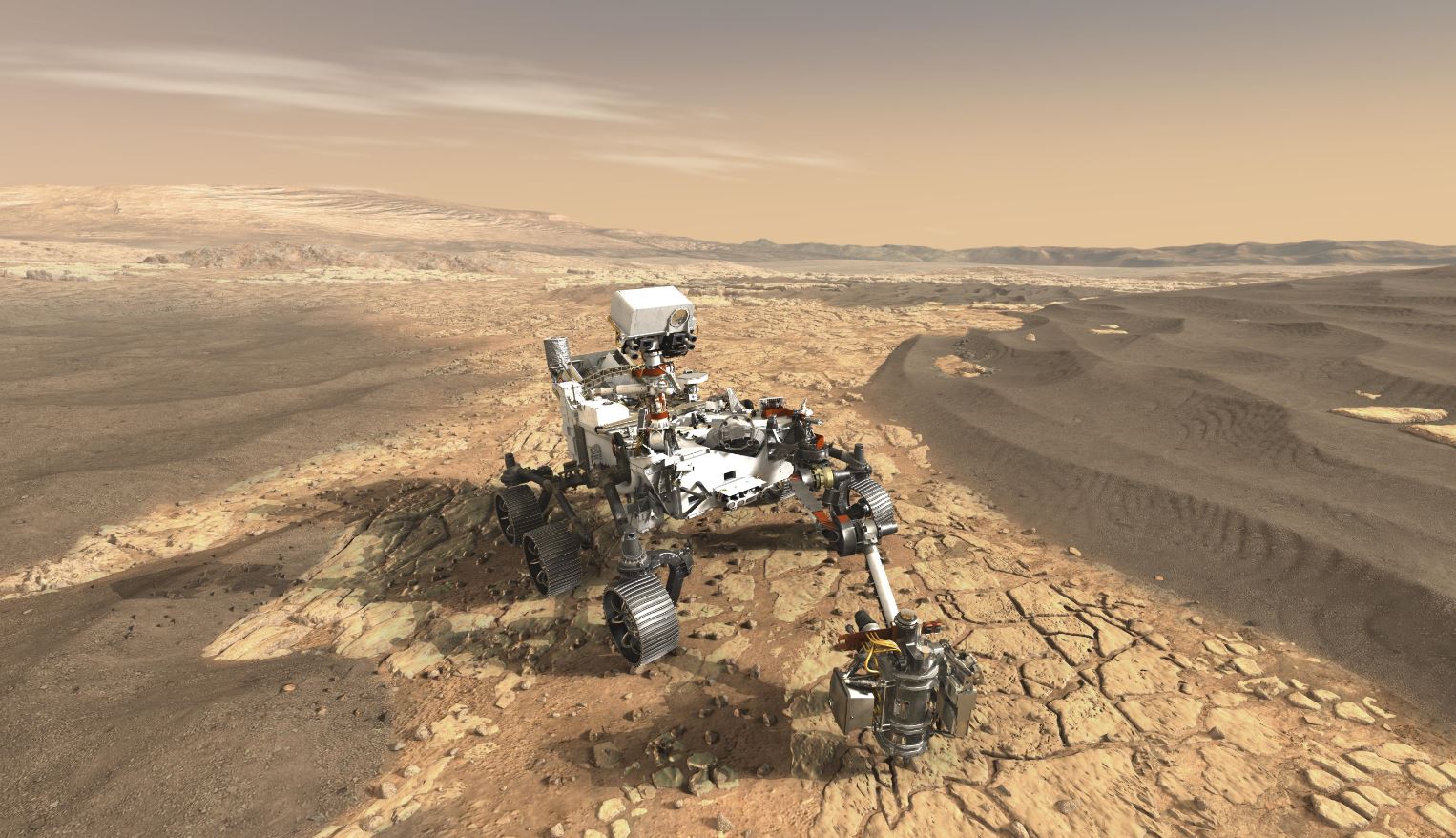

Bearings in Space

Each time the Perseverance Mars Rover collects or handles rock and regolith samples in Jezero Crater during its multiple-year mission on the surface of the red planet, key components from SKF, Gothenburg, Sweden, will facilitate those activities. Enabling the Mars Rover’s core operations in the harsh environment on Mars are Kaydon RealiSlim thin-section ball bearings, designed and manufactured by SKF at the company’s global thin-section bearing engineering center in Muskegon, and its recently expanded manufacturing hub in Sumter, USA.

These highly engineered components contribute to the survival of the rover’s main robotic arm, sample collecting turret, tool bit carousel and sample handling assembly during a months-long trip through space, and its function as intended on the Mars surface.

“The bearings we designed and built to help the rover perform its core science activities were based on several models of Kaydon thin-section ball bearings customized by our engineers to minimize weight and save space, while retaining maximum functionality and reliability for a mission where repair or replacement is simply not an option,” said Isidoro Mazzitelli, director of product development and engineering Americas. Space applications must be a small fraction of the weight of standard bearing assemblies.

In addition to the latest mission, SKF has a decades-long history as a supplier to global space programs, dating all the way back to NASA’s Apollo 11 mission. “Our company’s bearings, seals and other products have helped enable a wide range of spacecraft and missions for more than 40 years,” said John Schmidt, president, SKF USA Inc. “Our parts have flown on the previous space missions, dozens of commercial and government satellites, space-borne telescopes, a wide range of rocket launch vehicles and in astronaut’s spacesuits. When conditions become critical and applications demanding, engineering knowledge is the only way to success.”