Clarence Richard Company’s Tank Gauge

BY AsphaltPro Staff

Asphalt plant managers look for safety ideas to keep ground personnel out of harm’s way. To make it easier for personnel to measure liquid asphalt cement (AC) tank levels without physically climbing up and sticking the tank, the team at Clarence Richard Company, Minnetonka, Minnesota, developed the asphalt level tank gauge two decades ago. Over the years, they’ve updated it with remote indicators and pump cutout contacts. Here’s how it works.

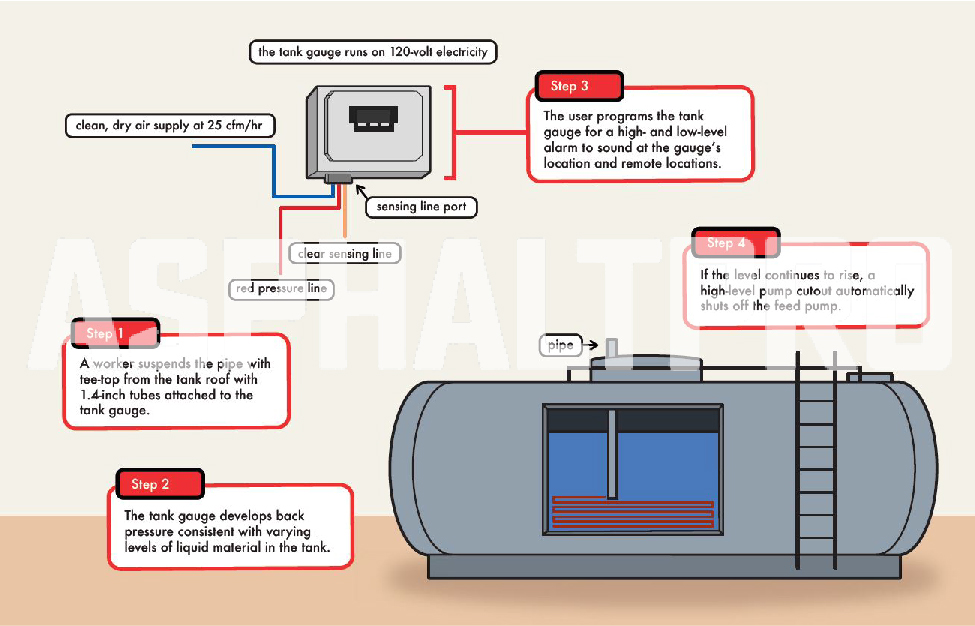

First, a worker installs the system by suspending a 2-inch-diameter pipe into the tank to be monitored. When the pipe is inserted to a distance that will keep it just above a coil heating obstruction in the tank, he attaches two sensing lines on the tee attached to the top of the pipe.

The sensing lines, made of quarter-inch-diameter nylon tubing, sense the asphalt level in the tank via back-pressure from the amount of force it takes to push liquid material out of the pipe. A transmitter within the gauge continually sends a signal from the tank gauge to the indicator-controller, which the plant manager can affix to a point at the tank farm or in the control house. The signal is transmitted digitally in tenths of an inch, and then can be converted to gallons or tons.

In the event that the level of material in the tank falls below a pre-determined level that the plant manager programs into the indicator-controller, a horn will sound and/or a pump will cut on or off. High-level alarms also warn personnel of impending problems.

The manufacturer states this system complies with the high liquid level alarms required by the Environmental Protection Agency 40 CFR Part 112.

The system can also be used with vertical tanks, which requires different installation.

For more information, contact Clarence Richard at (952) 939-6000.