Busby Reclaims with Roadtec SX-8s in the Granite State

BY Sue Luse

Recently, a longtime commercial customer came to Busby Construction Co. Inc., Atkinson, New Hampshire, with a problem: its industrial park in Salem needed pavement rehabilitation. Unfortunately, the pavement had been neglected for almost three decades. This surface hadn’t had any overlay or preventative measures performed at the recommended intervals, so the entire surface had declined to the point where it required complete reclamation, re-grading and re-paving.

Paul Busby, president of Busby Construction, explained, “In New England the surfaces deteriorate based on the freeze/thaw cycles that we go through. During the thawing period in the springtime, the base underneath the pavement becomes weakened and that can enhance the deterioration process.”

Since 1977, Busby Construction Co. Inc., has offered services ranging from asphalt reclamation to utility installations to site work. The company is a member of the New Hampshire Good Roads Association and the Associated General Contractors of America.

Fortunately, the company has built a strong reclamation business with the Roadtec SX series and is a leader in reclamation in New England.

“It’s not about getting a job done as fast as possible,” Busby explained. “It’s about giving a quality job to the customer and making sure the pace is appropriate for the conditions.”

He said, “I’ve tried to champion reclamation throughout our area by doing quality jobs that perform well and last…It’s not just a side business for us. It’s something for us to go out and promote to the industry.”

In fact, if a customer is new to reclamation, or if they don’t understand the process, Busby will spend time with them and explain it. “It’s a vital part of the business. I like to go see my jobs 15 years after they were done…I like to be able to send customers to those jobs as examples of our work.”

It’s not just customers who come to Busby Construction for expertise. “We get a lot of calls from engineers because we are known for accepting the new process and working with it and trying to use it when it’s needed,” said Busby.

Busby Construction crews have been using Roadtec stabilizers since 2012. They previously used the SX-7 and have moved to the newest model, the SX-8. For this industrial park job, they used two Roadtec SX-8 stabilizer/reclaimers.

Busby Construction has been a leading force in reclamation in the New England area with their finger on the pulse of the reclamation process; they’re able to spot potential complications or obstacles.

Busby said, “We experimented with the SX-7 and our guys like it.” After running the SX-7 for two seasons they moved to the SX-8. “We’ve been real happy with quality of the product that the machine puts out and speed at which we can go.”

The Busby team split the 30,000-square-yard project into two phases to accommodate the client’s tenant parking needs.

The fact that the Roadtec SX line is made in America is also important to Busby. “American-made means something to me. I like the fact that it is made in Chattanooga with American steel.”

Challenging Environment

Part of the reason Busby selected the SX-8 was due to the challenges the New England region presents: hard rock and varying depths. To deal with these challenges, they need machines that have high horsepower but remain maneuverable. The SX-8’s 755 horsepower and 83,000-pound weight is ideal for the New England reclamation jobs Busby Construction completes.

Part of the reason Busby selected the SX-8 was due to the challenges the New England region presents: hard rock and varying depths. To deal with these challenges, they need machines that have high horsepower but remain maneuverable. The SX-8’s 755 horsepower and 83,000-pound weight is ideal for the New England reclamation jobs Busby Construction completes.

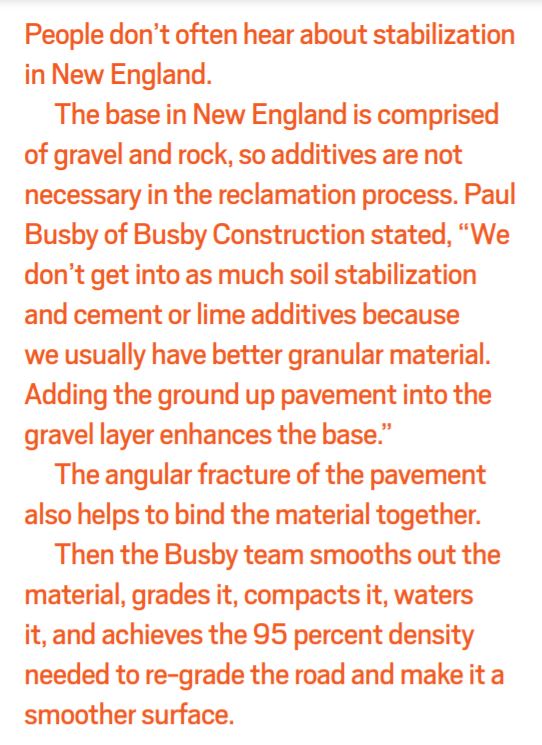

Hard Rock

“I like to say that New Hampshire is the granite state for a reason,” Busby said. “Our rock is very hard and the rock under that pavement is very hard. We do have certain things we deal with that other parts of the country don’t.”

Not only is the rock hard, it is also abrasive, which causes a lot of tooth wear on the stabilizers/reclaimers. “We have had many tooth experts come here and watch us and they are amazed with what happens and how much rock we deal with,” Busby said.

Varying Depths

In addition, New England jobs present the challenge of dealing with varying depth thickness in the same job. “A lot of our roads are old cart paths that got paved and widened and then paved again.” That process is generally repeated until the surface is reclaimed. As a result, Busby said it is not unusual to see pavement depths up to 18 inches.

For this industrial park job, the Busby Construction team used two Roadtec SX-8 stabilizer/reclaimers.

Typically, Busby explained, they measure the thickness of the base of the pavement and then reclaim twice that depth. But, they also consider the base material and make modifications when necessary.

“We don’t want to get down into the sub base material that’s underneath the gravel layer.”

For this industrial park they aimed for an 8-inch reclaimed base.

COVID Curveball

Once the depth of the industrial park project was determined, the Busby crew and the SX-8s were ready to get to work. However, due to the recent COVID-19 pandemic, the industrial park owner was not certain all of his tenants would be able to submit their rental payments on time. This uncertainty caused him to consider delaying the much-needed project, due to budget constraints.

Busby quickly found a solution.

Busby quickly found a solution.

The road in front of the business park was undergoing paving at the same time. Because Busby Construction had an established relationship with the asphalt supplier, they were able to negotiate pricing, based on volume. Then, Busby was able to extend payment terms to their customer. “That made the difference in him doing the job right now,” said Busby.

The customer was flexible, understanding the road and the industrial park needed to be on a similar schedule. However, his tenants still needed a place to park while the reclamation was happening.

Again, Busby came up with a solution.

They split the approximate 30,000-square-yard job into two phases and two sections. Because they were using two SX-8s on the job, they were able to work twice as fast. Tenants were able to park on the old pavement while the Busby Construction crew paved the first section—phase 1. “And then we shifted parking to phase 1 and we were able to get in and get phase 2 reclaimed,” Busby explained.

“Everything has gone with the schedule that we gave to the owner. We have also been able to reach production goals that we wanted,” Busby said.

Busby and his team tackled this job in the same way they approach all reclamation jobs, with a focus on quality. However, due to the pandemic, he had to think creatively. He relied on Roadtec machines, as well as his established partnerships with vendors, to achieve a quality result, on time.

Sue Luse is a writer for Roadtec Inc., an Astec company. For more information, visit www.roadtecinc.com.